Linear reciprocating motion mechanism

A technology of linear reciprocating motion and motion platform, applied in mechanical equipment, transmission devices, friction transmission devices, etc., can solve problems such as uncontrollable noise, and achieve the effects of controllable laws, convenient design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

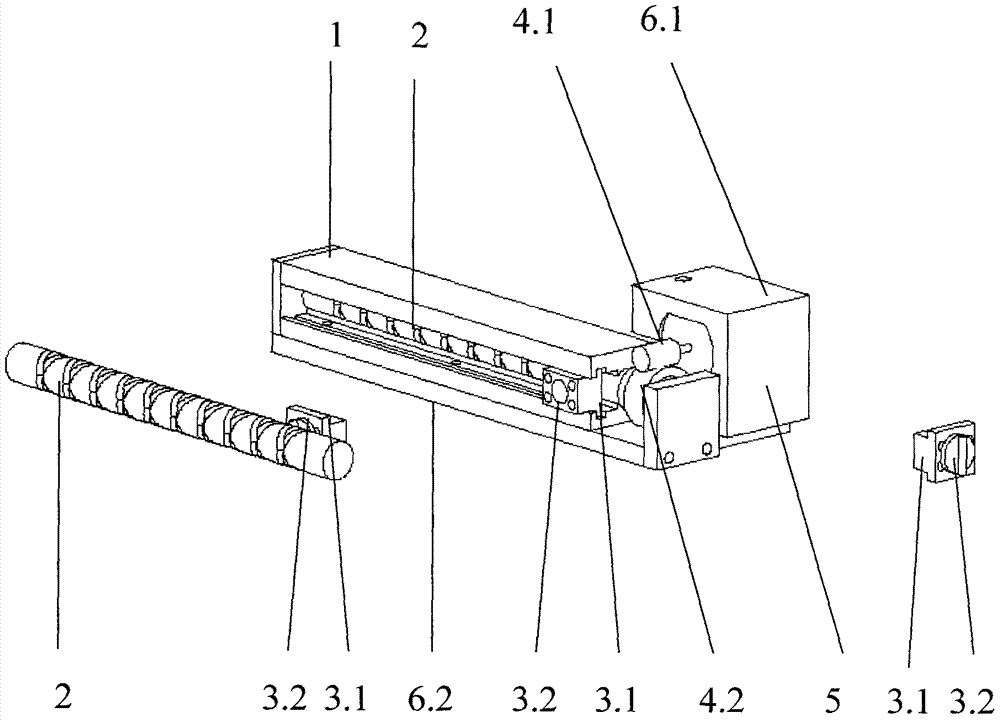

[0011] A linear reciprocating motion mechanism as shown in the figure, including 1 rotating shaft frame, 2 rotating shafts, 3.1 motion platform, 3.2 universal connection device, 4.1 motor gear, 4.2 rotating shaft gear, 5 built-in motors, 6.1, 6.2 fixed device, the rotating shaft is built into the rotating shaft frame, the rotating shaft frame is provided with a groove, the top of the frame is provided with a motion platform, the T surface of the platform is built with a frame groove, and the center of the motion platform is provided with a universal connection device. The circular concave rail connected to the rotating shaft protrudes from the bottom of the connecting device. The motor gear on the motor output shaft connects to the rotating shaft gear on the rotating shaft and controls its rotation. During the rotation, the raised position always follows the circular concave rail. The rail advances in the positive direction, and the direction change is realized at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com