Safety power drawer cabinet equipment

A drawer cabinet and electric power technology, which is applied in the direction of pull-out switch cabinets, electrical components, switchgear, etc., can solve the problems of increasing the risk of electric shock for maintenance personnel, inconvenient maintenance of electrical components, and potential safety hazards, so as to avoid the risk of electric shock and facilitate Maintenance and repair, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

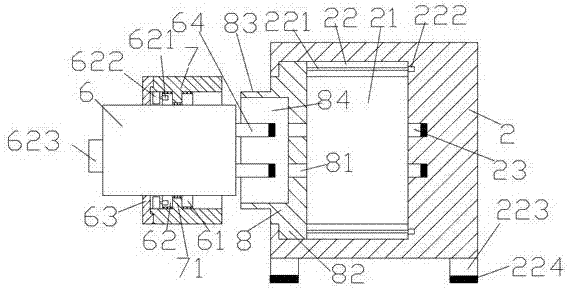

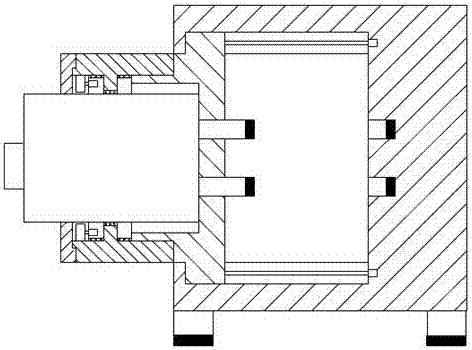

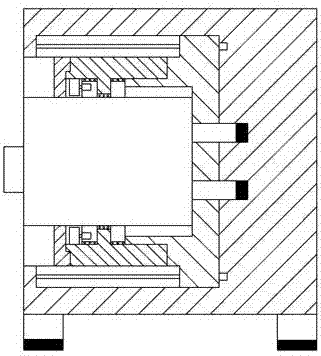

[0021] Such as Figure 1-Figure 5 As shown, a safe power drawer device of the present invention includes a cabinet base 2 and a drawer cabinet 6 arranged on the left side of the cabinet base 2, and a push chamber 21 is provided in the cabinet base 2, and the push chamber 21 The upper and lower sides are oppositely provided with a sliding cavity 22, the sliding cavity 22 is provided with a screw rod 221, the right end of the screw rod 221 is connected with the first motor 222, and the pushing cavity 21 is provided with a sliding Block 8, the upper and lower sides of the sliding block 8 are oppositely provided with a block 82 extending into the sliding cavity 22, the block 82 is threadedly connected with the screw rod 221, and the sliding The left side of the moving block 8 is provided with an external thread connecting portion 83, and the external thread connecting portion 83 is provided with a push groove 84, and the sliding block 8 on the right side of the push groove 84 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com