Water-fertilizer all-in-one machine

An all-in-one machine, water and fertilizer technology, applied in the direction of fertilization device, liquid fertilizer distribution, liquid fertilizer pressurized spreading method, etc., can solve the problems of affecting crops, retaining water, fertilizer and impurities, and large changes in water intake, so as to improve irrigation effect , stable pressure and consistent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

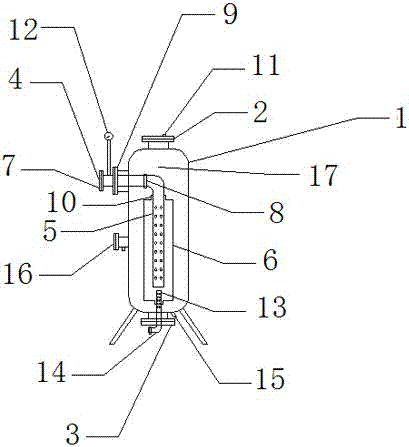

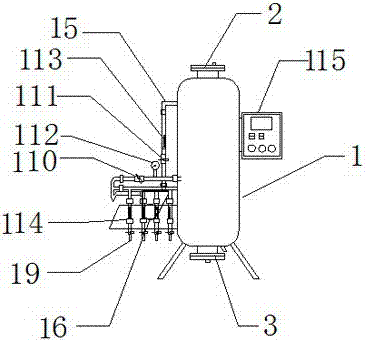

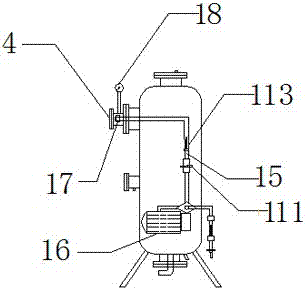

[0023] like Figure 1-3 As shown, a water and fertilizer integrated machine includes a tank body 1, and the tank body 1 is provided with an upper bin 2, a lower bin 3, and a water and fertilizer inlet 4, and the water and fertilizer inlet 4 is connected to a fertilizer inlet pipe 5 and a water inlet pipe respectively Then the water and fertilizer enter the inner cavity together, the upper bin is used to put in the filter screen and filter element, and it is also used as a replacement, and the lower bin is used to put in the sewage pipe; the water and fertilizer inlet is set at the upper end of the side of the tank body, The air pressure chamber 17 is formed on the top of the tank cavity, and the water and fertilizer enter from the upper end of the side. The filter element is an elbow structure, and the traditional straight-through filter element is changed into an elbow filter element. The pressure chamber, the amount of water and fertilizer in the tank will affect the air spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com