Connecting process of welded heat exchange tube and tube plate on heat exchanger of nuclear power plant with expanding rather than welding

A technology of heat exchangers and heat exchange tubes, which is applied in the field of expansion joints, can solve problems such as joint leakage, difficulty in repairing seal welding, and accelerated tube sheet corrosion, so as to achieve sealed connection, reduce weld reinforcement, and eliminate circular joints. The effect of degree deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

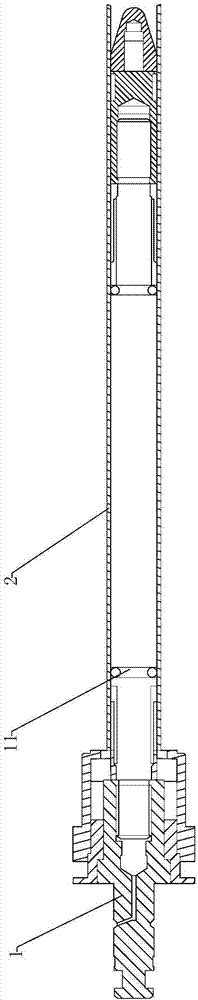

[0023] A connection process for welded heat exchange tubes on a heat exchanger of a nuclear power plant and a tube sheet that only expands but does not weld, comprising the following steps:

[0024] a. Clean the tube plate hole and grind the surface to be expanded of the welded heat exchange tube;

[0025] b. Initial positioning of welded heat exchange tubes and tube plate holes;

[0026] c. Apply low pressure to the welded heat exchange tube, and adjust the roundness of the welded heat exchange tube;

[0027] d. Continue for a period of time until the plastic deformation of the welded heat exchange tube is stable, and remove the low pressure applied to the welded heat exchange tube;

[0028] e. Apply high pressure to the welded heat exchange tube to compress the welded heat exchange tube and the tube sheet.

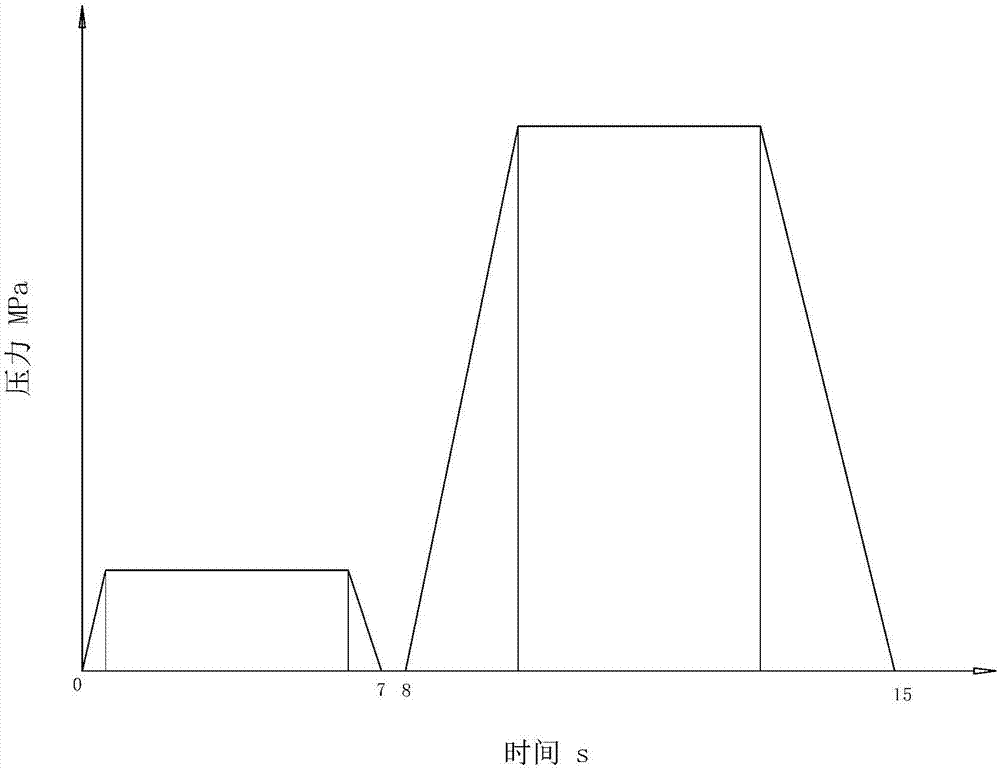

[0029] figure 1 0 to 7 seconds is the low pressure stage, 8 to 15 seconds is the high pressure stage, the low pressure is the pressure that can cause plastic deformat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com