Self-shrinking chemical reagent barrel

A self-shrinking, chemical technology, applied in the direction of packaging, variable capacity containers, external accessories, etc., can solve the problems of large chemical reagent barrels, human skin damage, and inconvenient use, and achieve easy sliding, convenient drug taking, The effect of taking the reagent conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

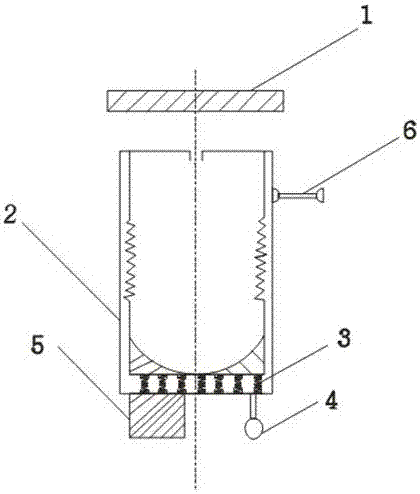

[0031] As shown in the accompanying drawing 1, it is a kind of self-shrinking chemical reagent barrel of the present invention, and the chemical reagent barrel comprises a barrel body and a bung 1 installed on the upper part of the barrel body; the barrel body 2 is a double-layer barrel body, wherein the outer barrel The bottom surface of the body is a plane, the inner wall shape of the bottom of the inner barrel body is an arc surface, and the outer wall shape is a plane; a spring 3 is arranged between the bottom surfaces of the inner barrel body and the outer barrel body, and at the same time, part of the barrel wall in the inner barrel body is in the shape of a telescopic bellows . The barrel wall height of the telescopic bellows in the inner barrel body accounts for 1 / 3 of the total height of the barrel wall of the inner barrel body.

[0032] The chemical reagent barrel also includes a base 5 and wheels, and the base 5 and wheels 4 are correspondingly installed under the b...

Embodiment 2

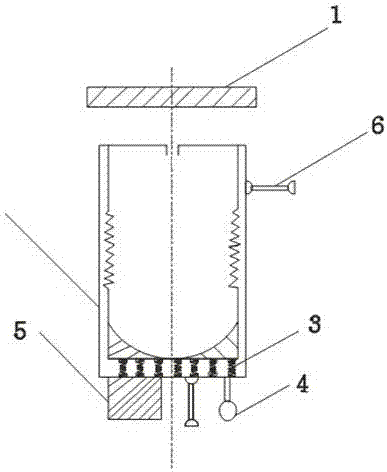

[0034] A self-shrinking chemical reagent barrel of the present invention, the chemical reagent barrel comprises a barrel body and a barrel cover 1 installed on the upper part of the barrel body; the barrel body 2 is a double-layer barrel body, wherein the bottom surface of the outer barrel body is a plane, and the inner barrel body The inner wall shape of the bottom is an arc surface, and the outer wall shape is a plane; a spring 3 is arranged between the bottom surface of the inner barrel body and the outer barrel body, and at the same time, the shape of part of the barrel wall in the inner barrel body is a telescopic bellows shape. The barrel wall height of the telescopic bellows in the inner barrel body accounts for 2 / 3 of the total height of the barrel wall of the inner barrel body.

[0035] The chemical reagent barrel also includes a base 5 and wheels, and the base 5 and wheels 4 are correspondingly installed under the barrel body 2 . The outer wall of the chemical reagen...

Embodiment 3

[0038] A self-shrinking chemical reagent barrel of the present invention, the chemical reagent barrel comprises a barrel body and a barrel cover 1 installed on the upper part of the barrel body; the barrel body 2 is a double-layer barrel body, wherein the bottom surface of the outer barrel body is a plane, and the inner barrel body The inner wall shape of the bottom is an arc surface, and the outer wall shape is a plane; a spring 3 is arranged between the bottom surface of the inner barrel body and the outer barrel body, and at the same time, the shape of part of the barrel wall in the inner barrel body is a telescopic bellows shape. The barrel wall height of the telescopic bellows in the inner barrel body accounts for 1 / 2 of the total height of the barrel wall of the inner barrel body.

[0039] The chemical reagent barrel also includes a base 5 and wheels, and the base 5 and wheels 4 are correspondingly installed under the barrel body 2 . The outer wall of the chemical reagen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com