screw strap

A screw belt and screw technology, applied in the field of hardware manufacturing, can solve the problems of easy loosening and insufficient tightening force of the screw belt, and achieve the effect of large tightening force, random adjustment of bending direction and angle, and good tightening force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

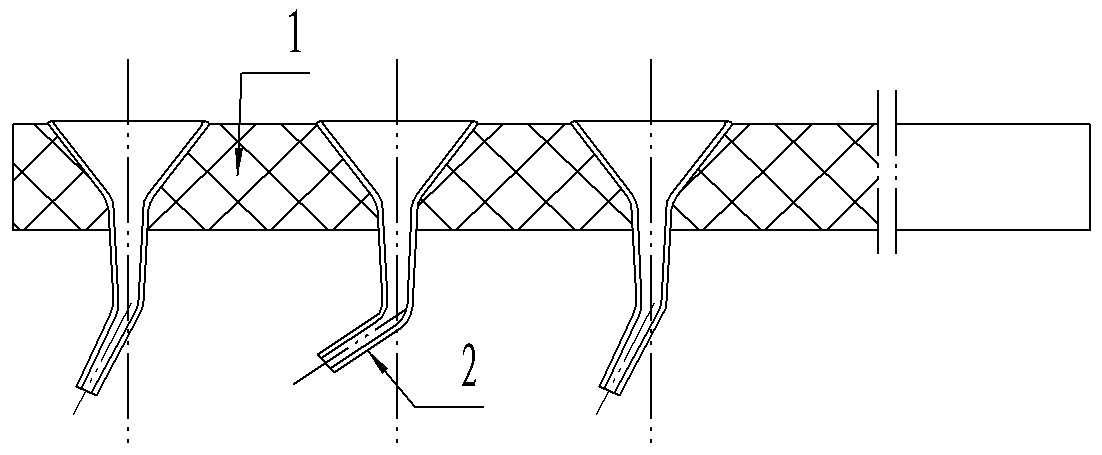

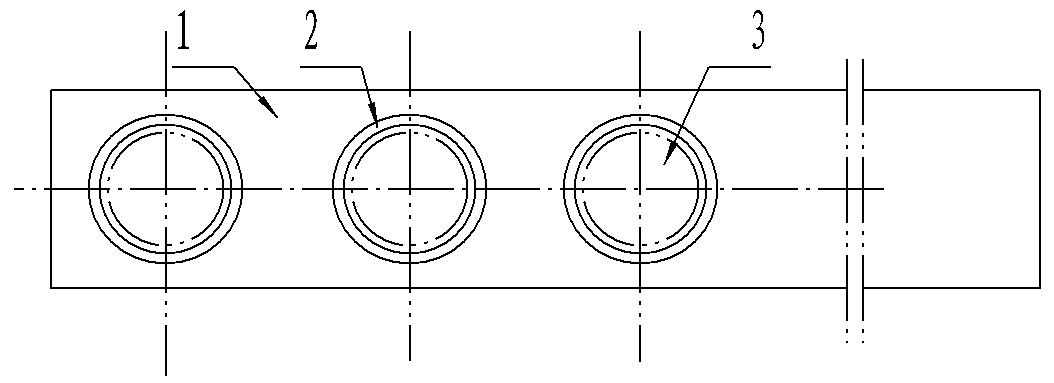

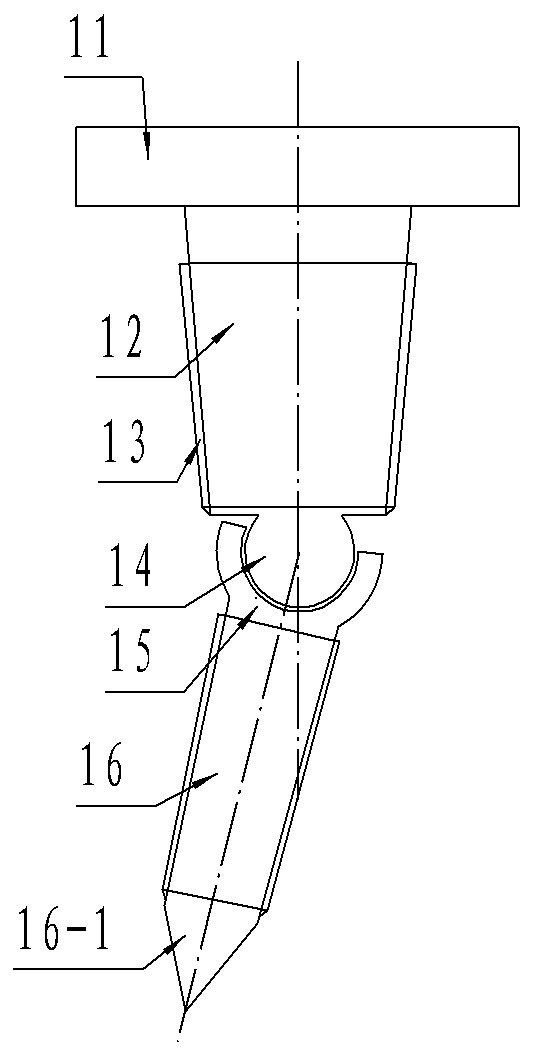

[0013] Such as figure 1 , figure 2 The screw belt shown includes a belt body 1, and a plurality of through holes are arranged on the belt body 1, and a guide nail 2 of a guide screw 3 is arranged in each through hole, and each guide nail 2 protrudes from the belt body The lower part of 1 is bent into an included angle, and the bending direction and angle of each nail guide 2 are not exactly the same; the guide nails of this screw belt can be bent in different directions and angles to maximize the increase Excellent fastening force, easy to use, and the bending direction and angle can be adjusted at will. figure 2 3 in the screw. The screw guide piece 2 of the screw band can have different bending directions and angles, so as to increase the fastening force after the screws are nailed in to the greatest extent. At the same time, it is convenien...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap