Visualized rheological method for evaluating emulsion stability

A technique for emulsion and stability, applied in the field of emulsion evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

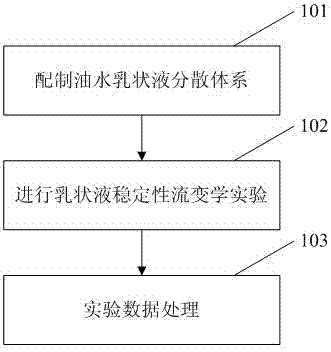

Image

Examples

Embodiment 1

[0022] Example 1: Partially hydrolyzed polyacrylamide polymer 1# is produced by Shengli Oilfield Baomo Chemical Co., Ltd., with a molecular weight of 22 million; crude oil and simulated formation water are provided by Shengli Oilfield, emulsifier (Changzhou Guohua Electric Co., Ltd.); Rheometer (MCR 301 Rheometer, Anton Paar, Austria).

[0023] The first step is to prepare an oil-water emulsion dispersion system with an oil-water ratio of 1:3 to make it fully emulsified. In a beaker, add 3 parts of simulated formation water (the polymer concentration is 1500mg / L), and then add a part of crude oil, put the mixed solution on the workbench of the emulsifier, turn on the switch of the emulsifier, and start emulsification to obtain a relative stable emulsion.

[0024] In the second step, a visual rheological experiment of emulsion stability was performed. Measurements were made using an MCR 301 rheometer from Anton Paar, Austria. The experimental operation is as follows: In the ...

Embodiment 2

[0026] Embodiment 2: Hydrophobic association polymer 2# is produced by Shengli Oilfield Baomo Chemical Co., Ltd., molecular weight is 20 million; Crude oil and simulated formation water are provided by Shengli Oilfield, emulsifier (Changzhou Guohua Electric Co., Ltd.); rheometer (MCR 301 rheometer, Anton Paar, Austria).

[0027] Step 1 and 2 are identical with embodiment 1;

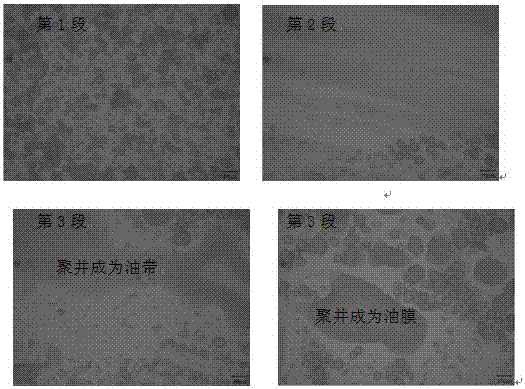

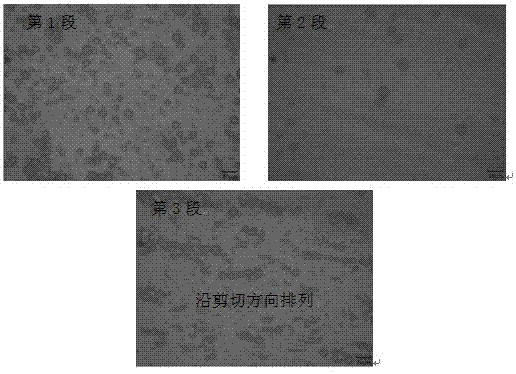

[0028] The third step is to process the experimental data and evaluate the stability and viscoelasticity of the emulsion. First observe the changes of the emulsion oil droplets during the experiment, whether the particle size of the oil droplets before and after high-speed shearing is uniform, whether the coalescence and demulsification of the oil droplets are obvious, and whether there is an oil film phenomenon. Such as image 3 and 4As shown, compared with Example 1, in the shock stage, the oil droplets are evenly distributed and the particle size is small. At this time, the storage modulus and loss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com