Rail clamping device and rail vehicle thereof

A technology of rail clamps and clips, which is applied in the direction of track contact components, brake components interacting with the track, brake types, etc., which can solve problems such as low reliability, mutual interference, and property loss, and achieve reliability and high safety, improved interference and wear, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

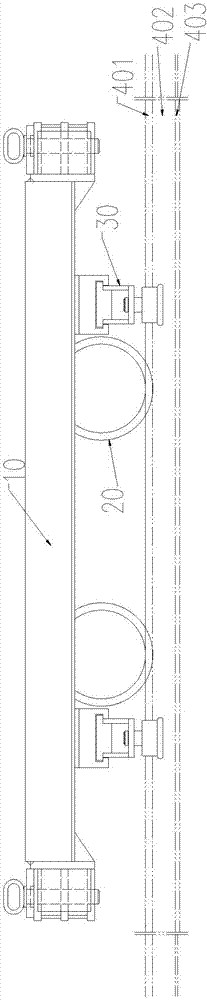

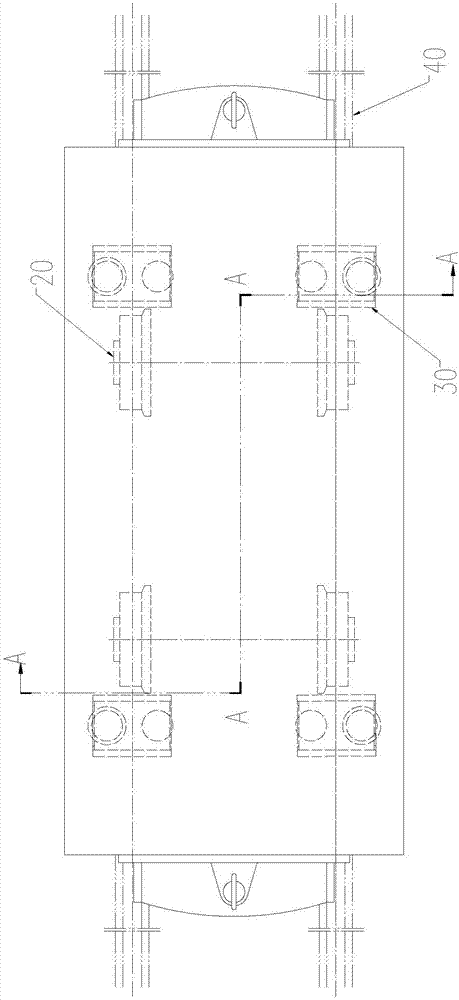

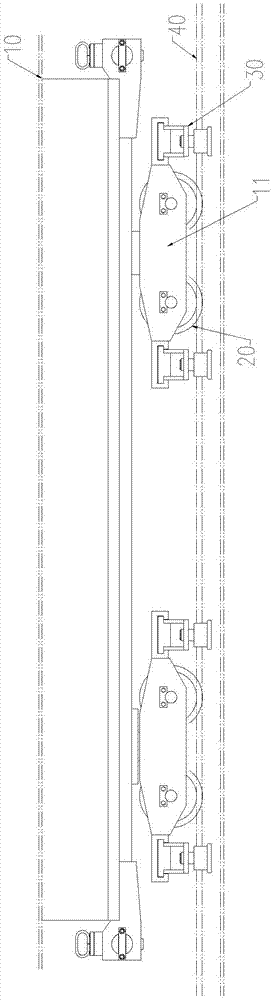

[0051] In the above-mentioned two embodiments, the rail holder 30 is the same type, which is combined below Figure 5 to Figure 7 Describe it.

[0052] Such as Figure 5 to Figure 7 As shown, the rail clamp 30 includes a fixed seat 31 and a sliding seat 32, the fixed seat 31 is connected with the vehicle frame 10 or the bogie 11, and its connection can be through welding or mechanical connection, preferably a detachable connection; the bottom of the fixed seat 31 is concave The hollow forms a T-shaped slot, and the top of the sliding seat 32 protrudes through the bottom of the fixed seat 31 and the top protrusion of the sliding seat 32 in a "T"-shaped nesting connection. The T-shaped slot is used as a guide groove, and the sliding seat 32 can be relatively fixed. Seat 31 slides left and right.

[0053] The sliding seat 32 has an integrated structure, the middle part is hollow and penetrates left and right, and the bottom is connected with a clamp, preferably left and right v...

Embodiment 4

[0063] Such as Figure 12 and Figure 13 As shown, the cross-section of the fixing seat 31 is positive T-shaped, wherein the lower circular guide hole penetrates left and right; the cross-section of the outer sliding seat 322 and the inner sliding seat 321 is L-shaped, wherein the upper circular fixing hole penetrates left and right, and they are opposite to each other. It is arranged on the left and right sides of the fixed seat 31; the slide bar 324 passes through the guide hole, and the outer slide seat 322 and the inner slide seat 321 are respectively fixed at the two ends of the slide bar 324. The slide bar 324 is preferably straight cylindrical, and the diameter of the guide hole Adapt to the diameter in the middle of the slide bar 324, the diameter of the fixing hole is adapted to the diameter of the two ends of the slide bar 324, preferably the diameter of the guide hole is greater than the diameter of the fixing hole, so that the two ends of the slide bar 324 can be m...

Embodiment 5

[0066] Such as Figure 14 and Figure 15 As shown, the cross section of the fixing seat 31 is concave, and the left and right side walls are respectively provided with circular fixing holes; the outer sliding seat 322 and the inner sliding seat 321 are against each other, and are fixedly connected to the upper part by screws 323 , the four corners are preferably distributed and fixedly connected by four screws 323, and the four screws 323 are preferably distributed in a positive trapezoidal shape. A circular sliding hole is provided at the center of the trapezoid, and the sliding hole penetrates the upper part of the outer sliding seat 322 and the inner sliding seat 321. And corresponding to the fixed hole, the guide rod 327 passes through the above-mentioned sliding hole, and its two ends respectively pass through the fixing hole and then fixed. The guide rod 327 is preferably straight cylindrical, and the diameter of the slide hole is compatible with the diameter in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com