A packaging film cutting control system and method

A control system and packaging film technology, applied in the computer field, can solve the problems affecting the alignment accuracy of the cutter and color mark, the inability to achieve precise position control, and the inability to perform real-time position and speed compensation, etc., to achieve accurate alignment and accurate Effects of Controlling and Improving Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

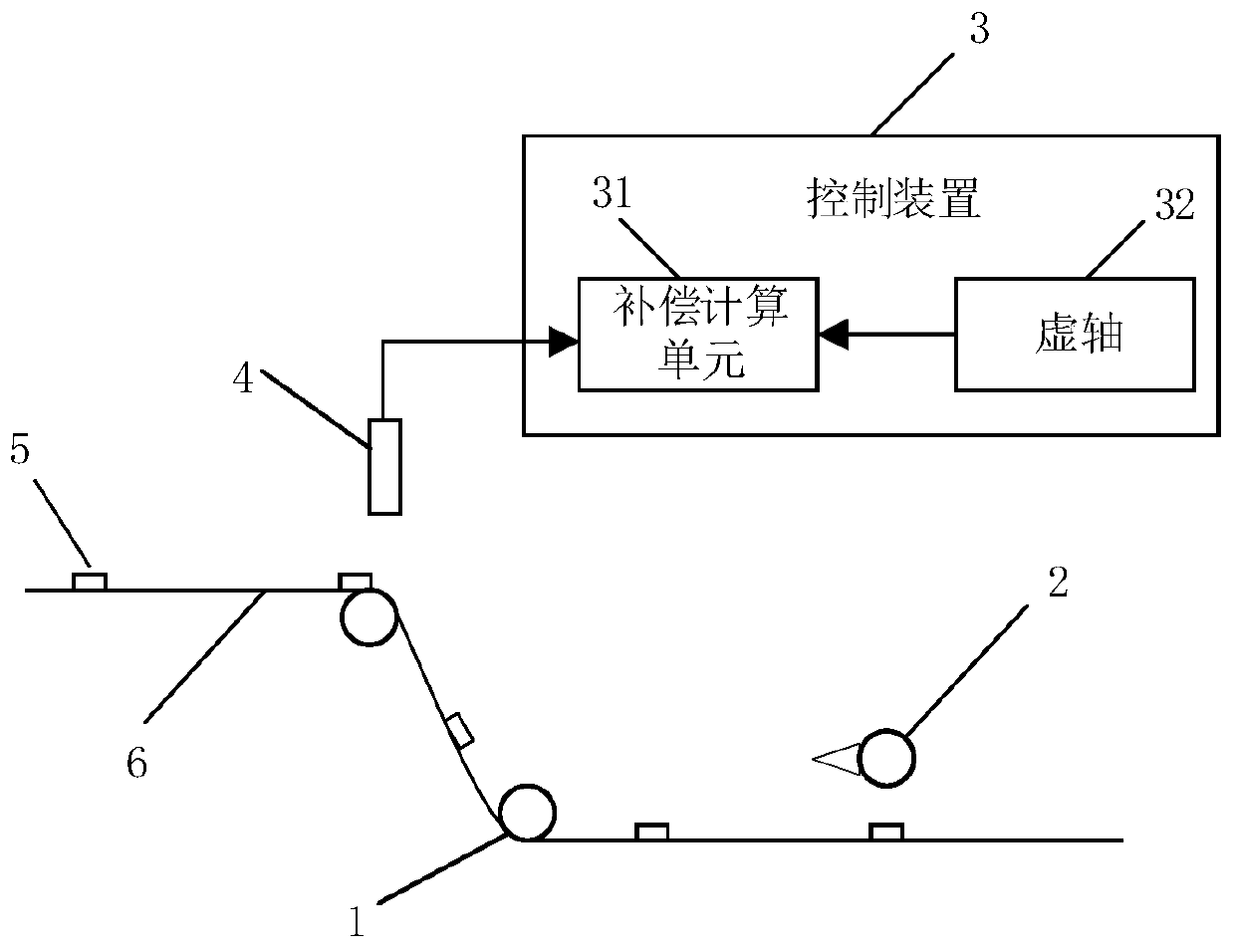

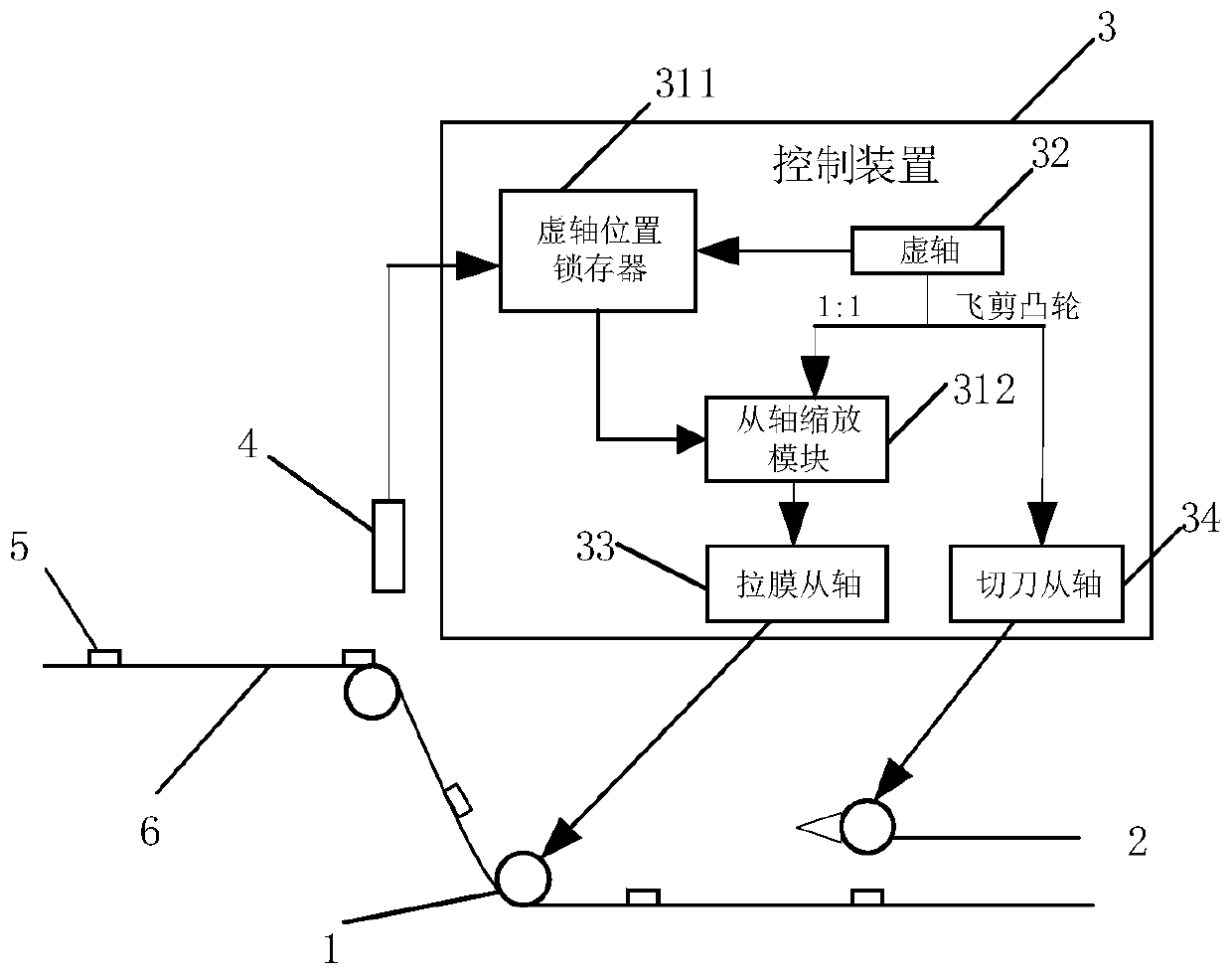

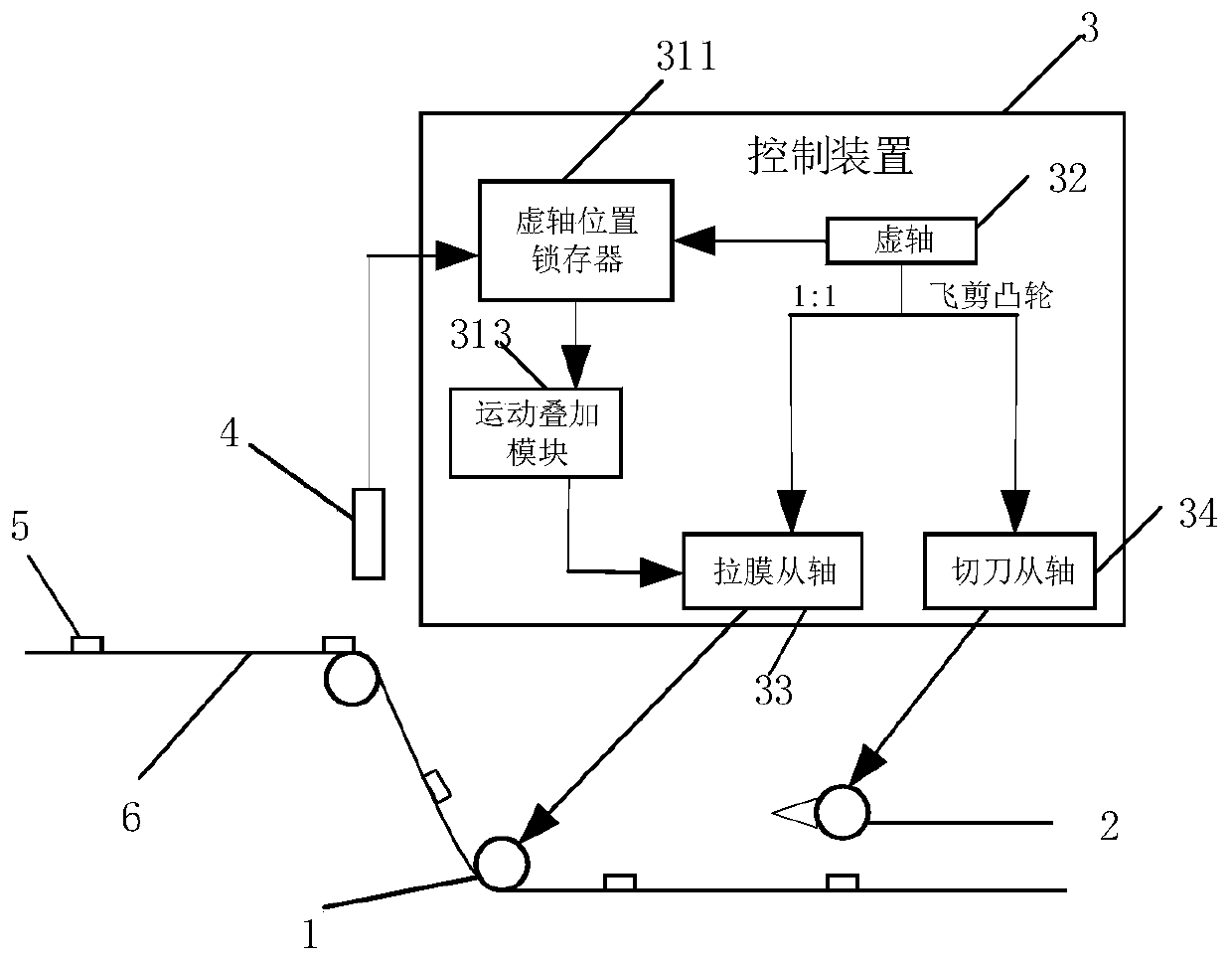

[0052] The embodiment of the present invention provides a packaging film shearing control system, see figure 1, the system includes a film pulling shaft 1, a cutter shaft 2, a control device 3, and a color mark sensor 4 arranged on the running path of the packaging film 6 and located upstream of the film pulling shaft 1; the control device 3 includes a compensation calculation unit 31 and The imaginary shaft 32, wherein the imaginary shaft 32 forms a cam engagement relationship with the film pulling shaft 1 and the cutter shaft 2.

[0053] The color mark sensor 4 is used to send a detection signal every time a color mark 5 on the packaging film 6 is detected;

[0054] The compensation calculation unit 31 is used to calculate an adjustment amount according to the virtual axis position corresponding to the detection signal, and the adjustment amount is used to adjust the operation of the film pulling axis 1 .

[0055] It should be noted that the film pulling shaft is used to pu...

Embodiment 2

[0082] The embodiment of the present invention provides a method for controlling the shearing of the packaging film by using the packaging film shearing control system in the above embodiment, see Figure 5 , the packaging film shearing control method comprises:

[0083] S1. The color mark sensor sends a detection signal to the control device every time a color mark on the packaging film is detected; the color mark sensor is arranged on the running path of the packaging film and located upstream of the film pulling axis;

[0084] S2. The control device calculates an adjustment amount according to the position of the virtual axis corresponding to the detection signal, and adjusts the operation of the film-drawing shaft according to the adjustment amount; the film-drawing shaft, the cutter shaft and the virtual shaft form a cam engagement relationship.

[0085] In a preferred embodiment, the control device calculates the adjustment amount according to the virtual axis position c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com