Automatic pig feeding system and control method thereof

An automatic, hog-friendly technology, applied in animal feeding devices, non-electric variable control, control/regulation systems, etc., can solve the problem of overfilling, health impact of hogs, and failure to automatically feed ingredients into the batching bucket according to the preset ratio. Adding and other issues to achieve the effect of promoting digestion and absorption and improving food appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

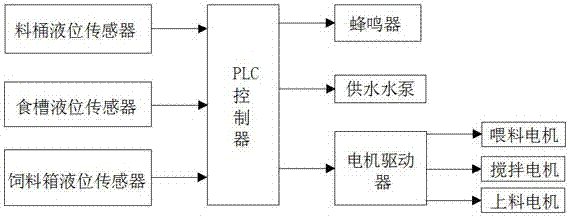

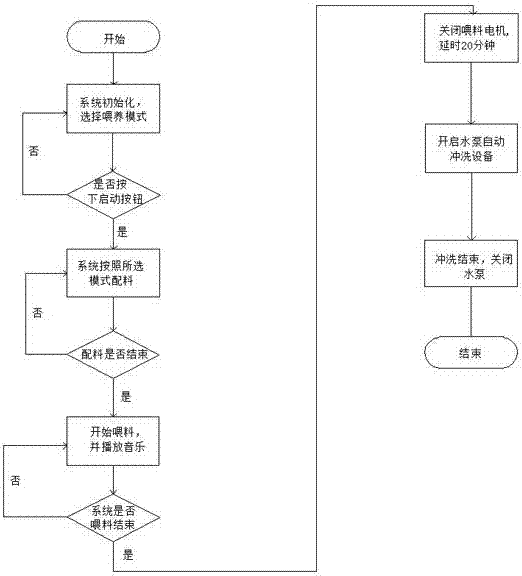

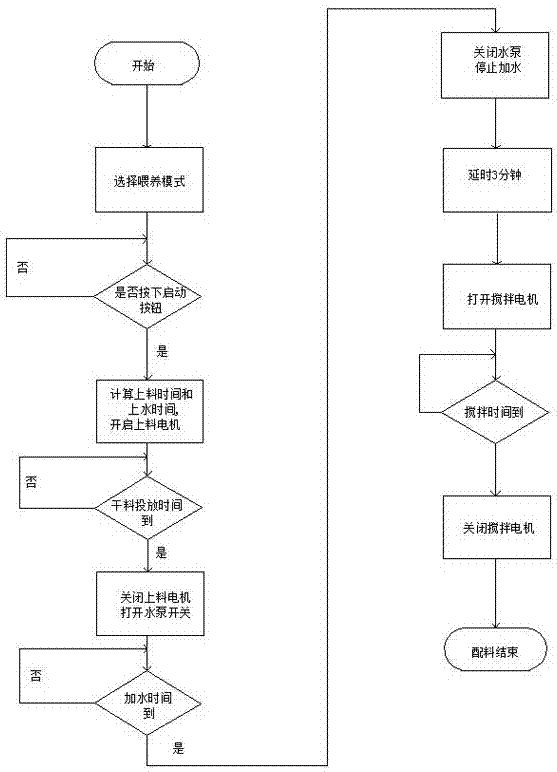

[0046] As shown in the figure, an automatic pig feeding system includes a batching device, a feeding device, a flushing device and a controller. The batching device includes a feeding device, a water supply device and a stirring device. The feeding device is used to drive the feed box The dry material inside is transported to the batching tank; the water supply device is used to supply water to the batching tank; the stirring device is used to mix and stir the dry material and water added to the batching tank in a certain proportion to obtain liquid dry material;

[0047] The feeding device is used to put the prepared liquid dry material into the trough for the pigs to eat. Among them, the feeding device, water supply device, stirring device and automatic feeding device are all controlled by the controller; the automatic flushing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com