A kind of technology that utilizes acid cellulase to remove cotton cloth scratch marks

An acid cellulase, cotton cloth technology, applied in the field of dyeing and finishing, can solve the problems of affecting the appearance quality of cotton cloth, unable to remove scratches and prints, etc., and achieve the effects of improving hydrolysis and polishing, removing scratches and improving smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

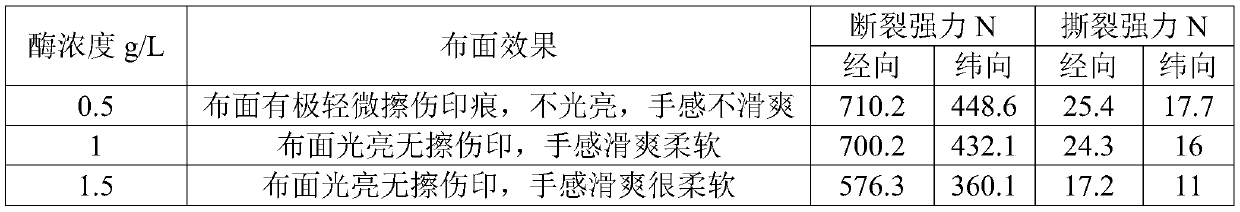

[0028] The specific technological process that present embodiment utilizes acid cellulase to remove cotton cloth scratch marks is as follows:

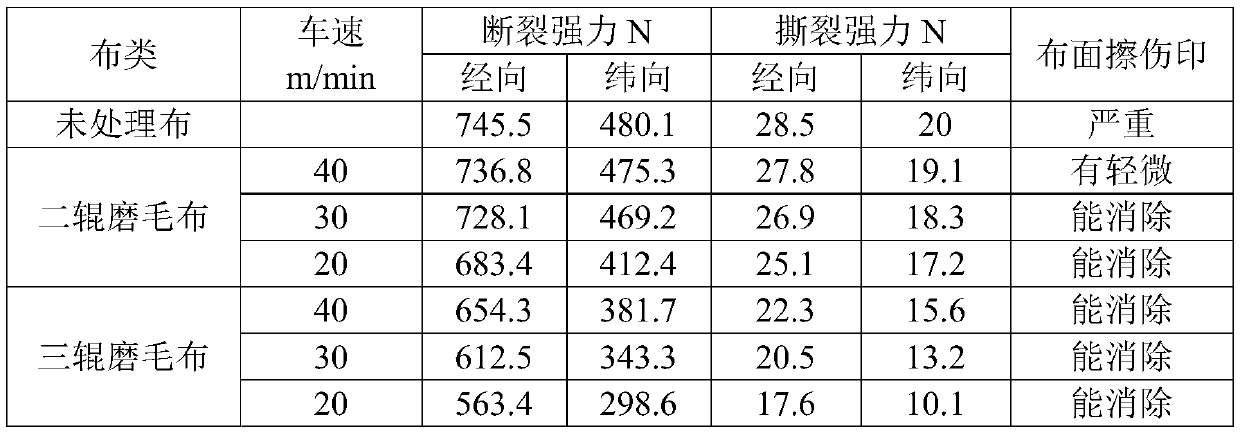

[0029] A. Sanding: pass the cotton cloth through the sanding machine, and use the carbon roller in the sanding machine to lightly sand the cotton cloth with scratch marks; among them, two rollers are used for sanding, and the speed of the sanding machine is 30m / min.

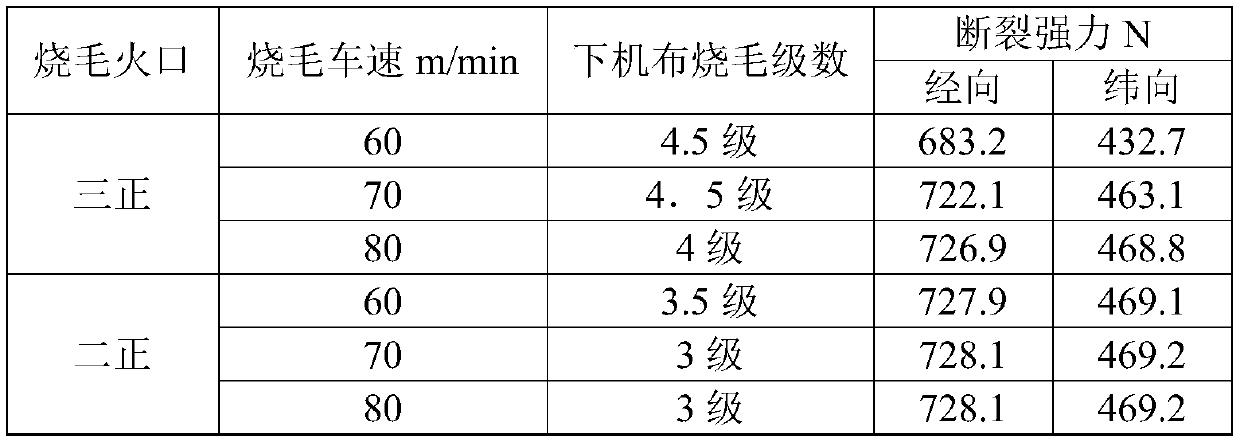

[0030] B. Singeing: Singeing the sanded cotton cloth through a gas singeing machine; wherein, the gas singeing machine adopts three normal burners, the flame temperature is 900 ° C, the distance between the flame and the fabric is 1 cm, and the speed of the singeing machine is 1 cm. 70m / min.

[0031] C. Mercerizing: Pass the singeed cotton cloth through a mercerizing machine, and carry out mercerizing treatment under the action of caustic soda solution; wherein, the concentration of caustic soda solution is 240g / L, the temperature is 22°C, the tension of the mercerizing ...

Embodiment 2

[0037] The specific technological process that present embodiment utilizes acid cellulase to remove cotton cloth scratch marks is as follows:

[0038] A. Sanding: pass the cotton cloth through the sanding machine, and use the carbon roller in the sanding machine to lightly sand the cotton cloth with scratch marks; among them, two rollers are used for sanding, and the speed of the sanding machine is 30m / min.

[0039] B. Singeing: Singeing the sanded cotton cloth through a gas singeing machine; wherein, the gas singeing machine adopts three normal burners, the flame temperature is 900°C, the distance between the flame and the fabric is 2cm, and the speed of the singeing machine is 70m / min.

[0040] C. Mercerizing: Pass the singeed cotton cloth through a mercerizing machine, and carry out mercerizing treatment under the action of caustic soda solution; wherein, the concentration of caustic soda solution is 240g / L, the temperature is 25°C, and the tension of the mercerizing machi...

Embodiment 3

[0046] The specific technological process that present embodiment utilizes acid cellulase to remove cotton cloth scratch marks is as follows:

[0047] A. Sanding: pass the cotton cloth through the sanding machine, and use the carbon roller in the sanding machine to lightly sand the cotton cloth with scratch marks; among them, two rollers are used for sanding, and the speed of the sanding machine is 30m / min.

[0048] B. Singeing: Singeing the sanded cotton cloth through a gas singeing machine; wherein, the gas singeing machine adopts three normal burners, the flame temperature is 900°C, the distance between the flame and the fabric is 2cm, and the speed of the singeing machine is 70m / min.

[0049] C. Mercerizing: Pass the singeed cotton cloth through a mercerizing machine, and carry out mercerizing treatment under the action of caustic soda solution; wherein, the concentration of caustic soda solution is 240g / L, the temperature is 30°C, the tension of the mercerizing machine i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com