Liquid crystal dripping nozzle, liquid crystal dripping device and liquid crystal dripping method

A liquid crystal dropping and liquid crystal technology, which is applied to the devices, instruments, coatings and other directions that apply liquid to the surface, can solve the problems of light leakage and easy puncture, and can reduce the impact, reduce the probability of corner light leakage, and reduce the risk of puncture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

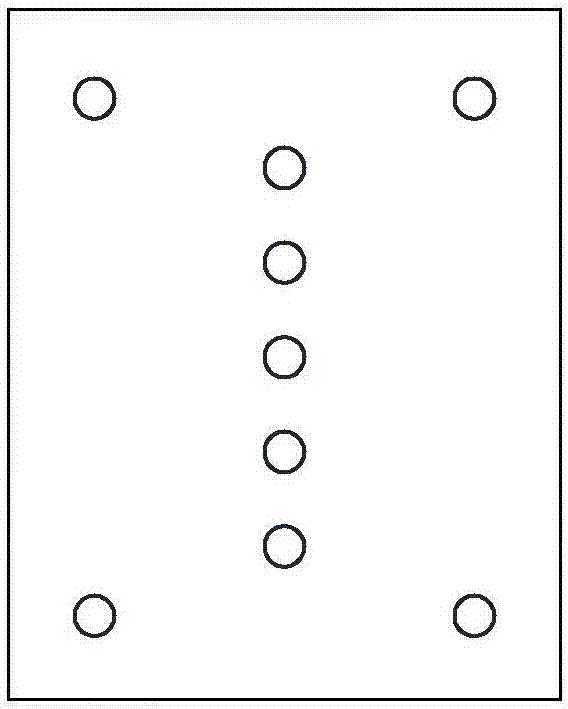

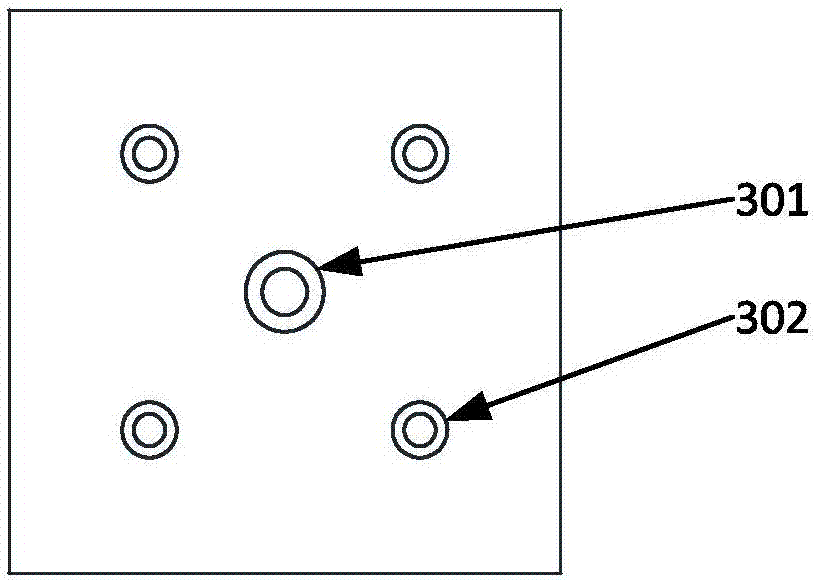

[0055] Such as figure 2 As shown, Embodiment 1 of the present invention provides a liquid crystal drop nozzle, including a main drop nozzle 301 and a plurality of auxiliary drop nozzles 302 , and the plurality of auxiliary drop nozzles 302 are arranged around the main drop nozzle 301 . Specifically, a plurality of auxiliary drip nozzles 302 are arranged around the main drip nozzle 301 in a uniform circumferential manner around the main drip nozzle 301 ; or, a plurality of auxiliary drip nozzles 302 are symmetrically arranged on both sides of the main drip nozzle 301 .

[0056]In the specific operation, through the setting of the above-mentioned main drip nozzle 301, the liquid crystal drop setting operation in the central area of the liquid crystal pattern can be realized, and the above-mentioned multiple auxiliary drip nozzles 302 that are uniformly distributed or symmetrically arranged on the circumference can realize the edge of the liquid crystal pattern. The liquid cry...

Embodiment 2

[0065] Such as Figure 4 As shown, Embodiment 2 of the present invention provides a kind of liquid crystal dripping device, comprises the liquid crystal drip nozzle described in Embodiment 1, also includes support 40, disperser 30 and liquid crystal storage irrigation (LC Bottle) 10, and disperser 30 sets On the bracket 40, the diffuser 30 communicates with the liquid crystal storage tank through a pipeline.

[0066] In this embodiment, the above-mentioned liquid crystal drip nozzle is arranged on the working end surface of the disperser 30; the main drip nozzle 301 is located in the middle of the working end surface 303, and a plurality of auxiliary drip nozzles 302 are located on the working end surface 303 and arranged around the main drip nozzle 301; The above-mentioned disperser 30 is also provided with a first valve and a second valve, the first valve is connected to the main drip nozzle 301, the second valve is connected to the auxiliary drip nozzle 302, and the main dr...

Embodiment 3

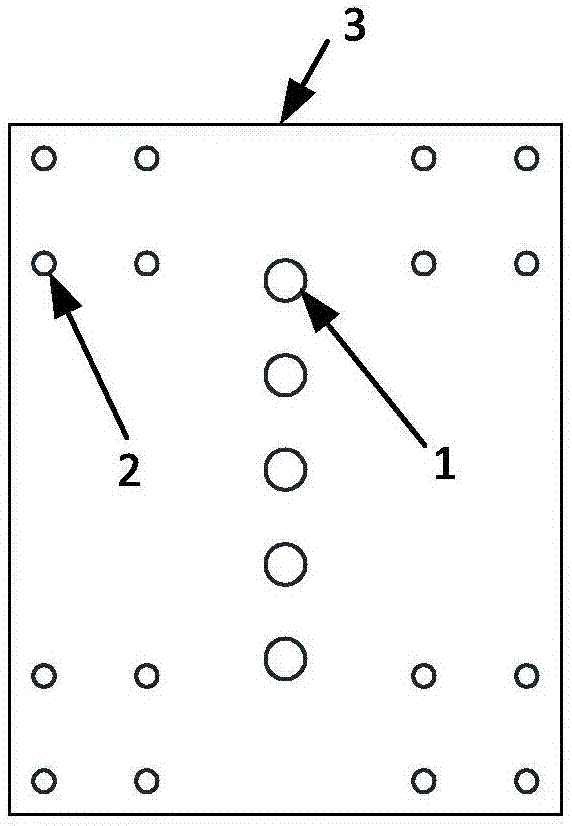

[0073] Embodiment 3 of the present invention provides a liquid crystal dripping device. The main structure is similar to that of Embodiment 2, and also includes a bracket and a disperser; for the specific configuration of the main structure, please refer to the description in Embodiment 2. The purpose here is to illustrate the two difference between.

[0074] Such as Image 6 As shown, in this embodiment, the above-mentioned position moving mechanism includes oblique moving rails 306 uniformly distributed around the main drip nozzle 301, and one end of the above-mentioned oblique moving rail 306 points to the main drip nozzle 301; that is, the above-mentioned oblique moving rail 306 Taking the main drip nozzle 301 as a circle, it is evenly distributed around the main drip nozzle 301 in a scattered shape; through the above-mentioned setting of the oblique moving track 306, the position adjustment between the auxiliary drip nozzle 302 and the main drip nozzle 301 can be realized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com