Automobile charging pile

A car charging and charging cable technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of people stepping on, car rolling, charging cable life shortening, charging cable insulation damage, etc., to reduce labor costs. The effect of manually retracting the charging cable, preventing accidental electric shock, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

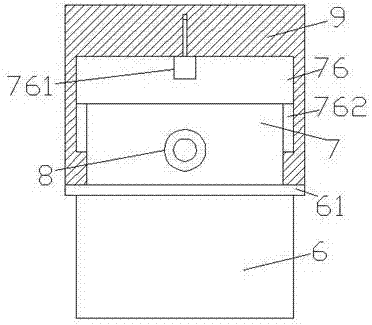

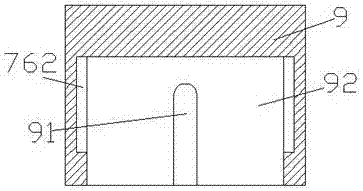

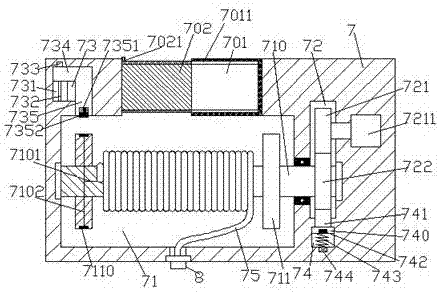

[0026] Such as Figure 1-Figure 8 As shown, a car charging pile of the present invention includes a support column 6, a body 7 fixed on the top of the support column 6, and a lifting protective cover 9 arranged outside the top of the body 7, and the body 7 is provided with The first cavity 71, the body 7 on the right side of the first cavity 71 is provided with a second cavity 72, and the body 7 above the left side of the first cavity 71 is provided with a first slide cavity 73, the body 7 below the second cavity 72 is provided with a second sliding cavity 74, the first cavity 71 is provided with a rotating shaft 710 extending to the left and right sides, and the rotating shaft The extension section on the right side of 710 runs through the inner wall of the body 7 and extends into the second cavity 72 and is connected in a rotational fit. The rotating shaft 710 in the first cavity 71 is symmetrically provided with baffles 711 left and right, The rotating shaft 710 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com