Synchronous construction method of near height-unequal foundation pit

A construction method and synchronous construction technology, which can be used in basic structure engineering, excavation, construction, etc., can solve the problems of waste of steel bars, concrete, poor connection conditions of steel bars, and large workload of planting steel bars, so as to reduce the amount of engineering and ensure the integrity. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solution of the construction method of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the description.

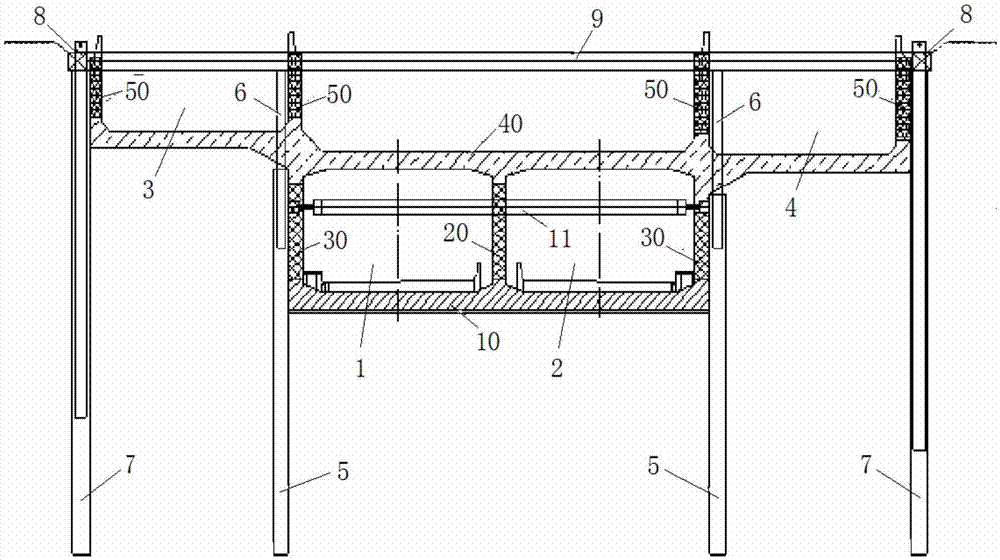

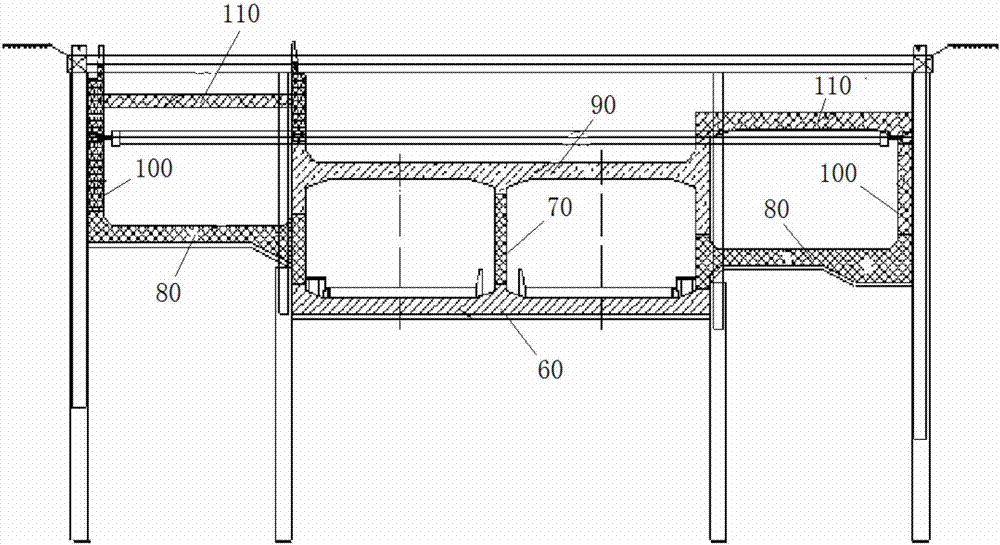

[0059] The construction method of the present invention includes figure 1 The construction of the initial section shown with the figure 2 The terminal section shown is constructed in two phases.

[0060] Step 1, construction steps of a typical section in the initial section:

[0061] Step 1, adjust the height of the ground connection wall and the position of the steel support:

[0062] (11) adjust the height of ground connection wall 5, the height of ground connection wall 5 is below the bottom plate 40 of 2 of the first deep foundation pit 1 and the second deep foundation pit all the time;

[0063] (12) Adjust the position of the steel support. When the height difference between the first deep foundation pit 1, the second deep foundation pit 2, the third shallow foundation pit 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com