Surgical cart with push handle

An operating table and handle technology, applied in the field of medical devices, can solve problems such as large detachment risk, poor stability, fatigue or discomfort, and achieve the effect of reducing the risk of slippage, increasing stability and reducing discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

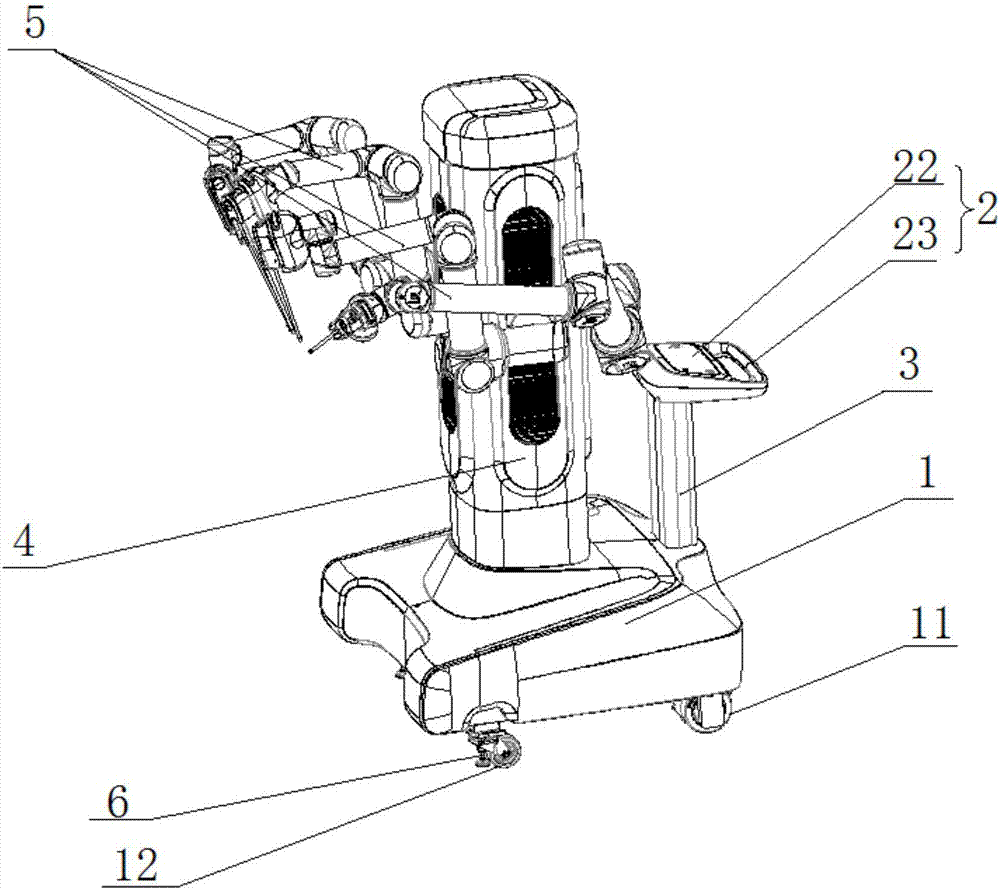

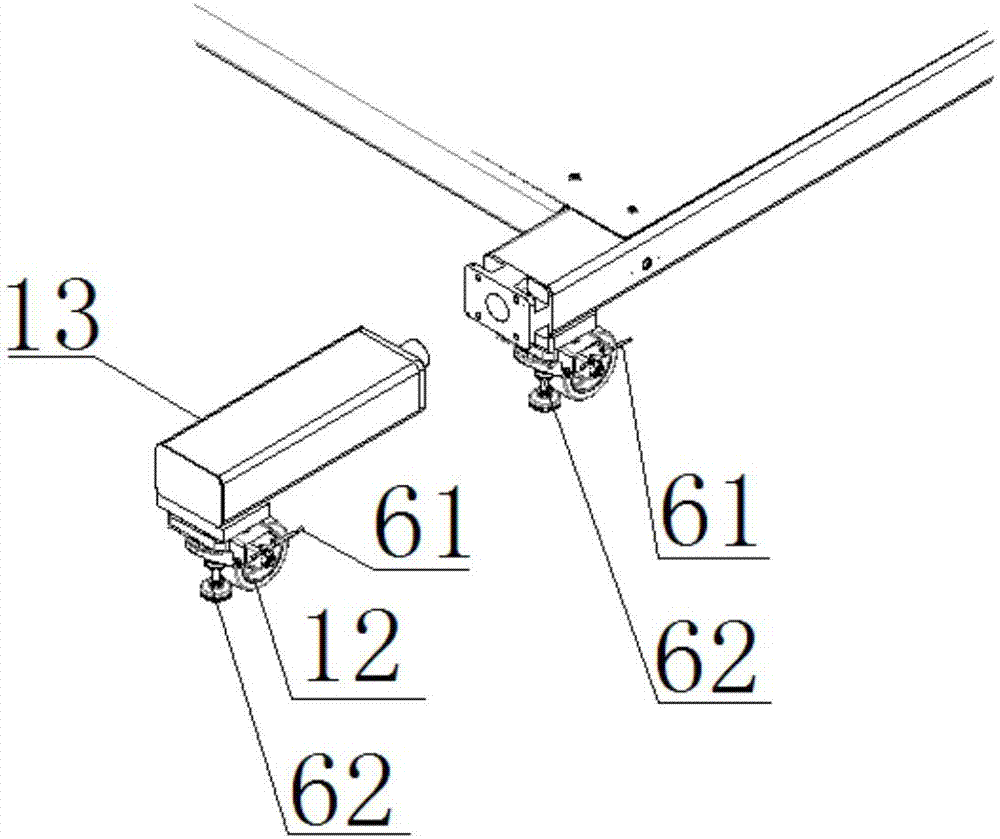

[0033] Such as figure 1 and Figure 4 , showing a surgical trolley with push handles, including:

[0034] base1;

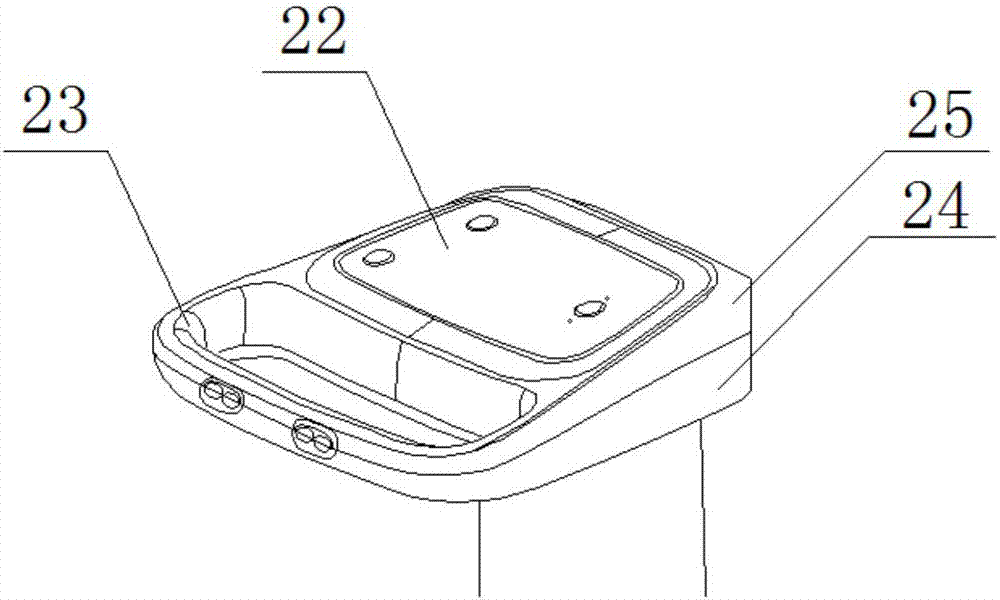

[0035] The push handle 2 is provided with reinforcing ribs 21 at the corners of the push handle 2, the push handle 2 includes a display screen 22 and a handle 23, and the side wall of the handle 23 is configured in an arc shape.

[0036] A support column 3 disposed near the edge of the base 1, the support column 3 is used to support the push handle 2;

[0037] The column 4 is provided with a mechanical arm 5 for assembling surgical instruments.

[0038] Because the wall thickness at the corner of the handle 23 is relatively thin, when the operating trolley is pushed, the thrust per unit area at the corner of the handle 23 is relatively large. The position is provided with ribs 21, which can disperse the thrust and prolong the life of the push handle.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com