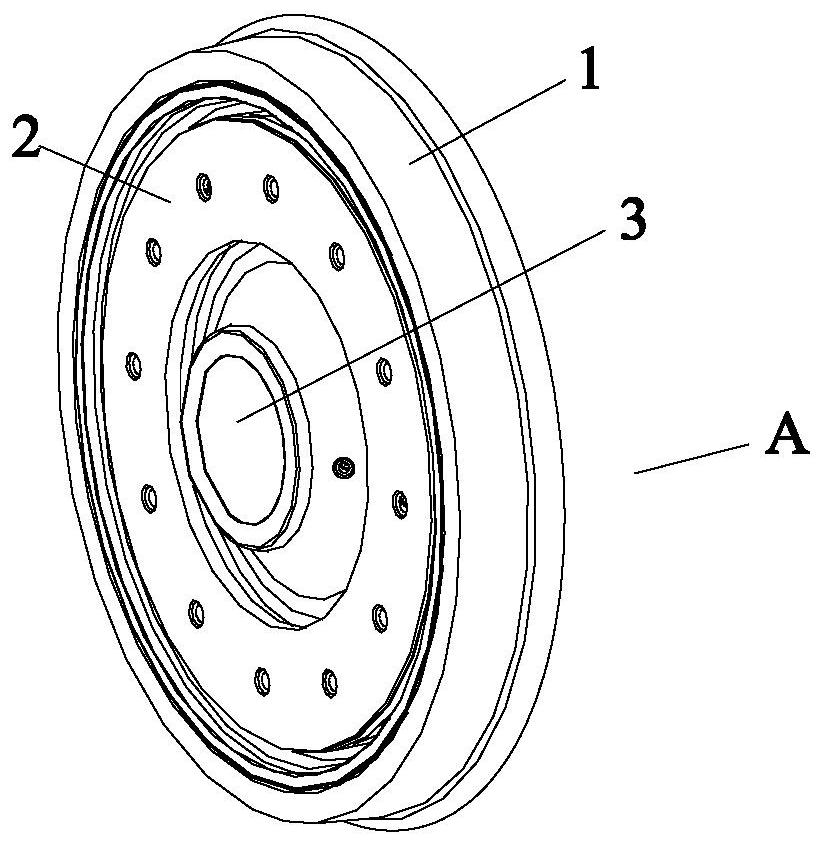

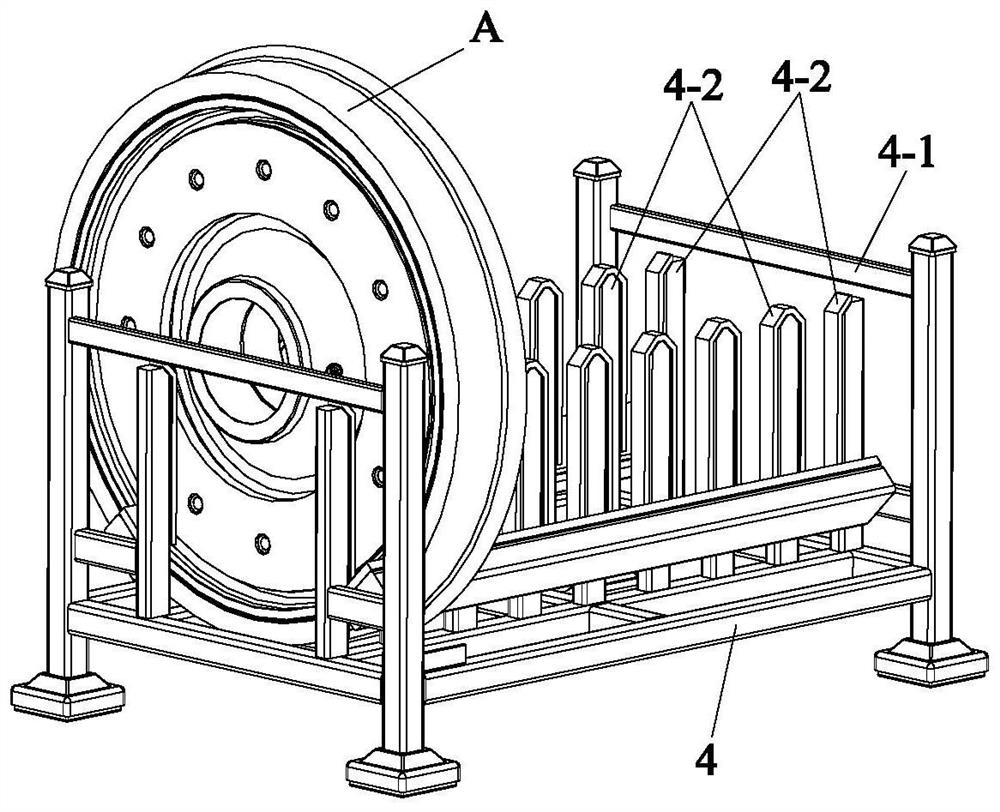

Pre-assembling device for wheel-mounted brake disc of motor train unit

A brake disc and pre-assembly technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to guarantee the quality and safety of assembly operations, bumps and scratches on wheel-mounted brake discs or hubs, brake disc installation and Acceptance obstacles and other problems, to achieve the effect of reducing the risk of slippage, reducing bumps and scratches, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

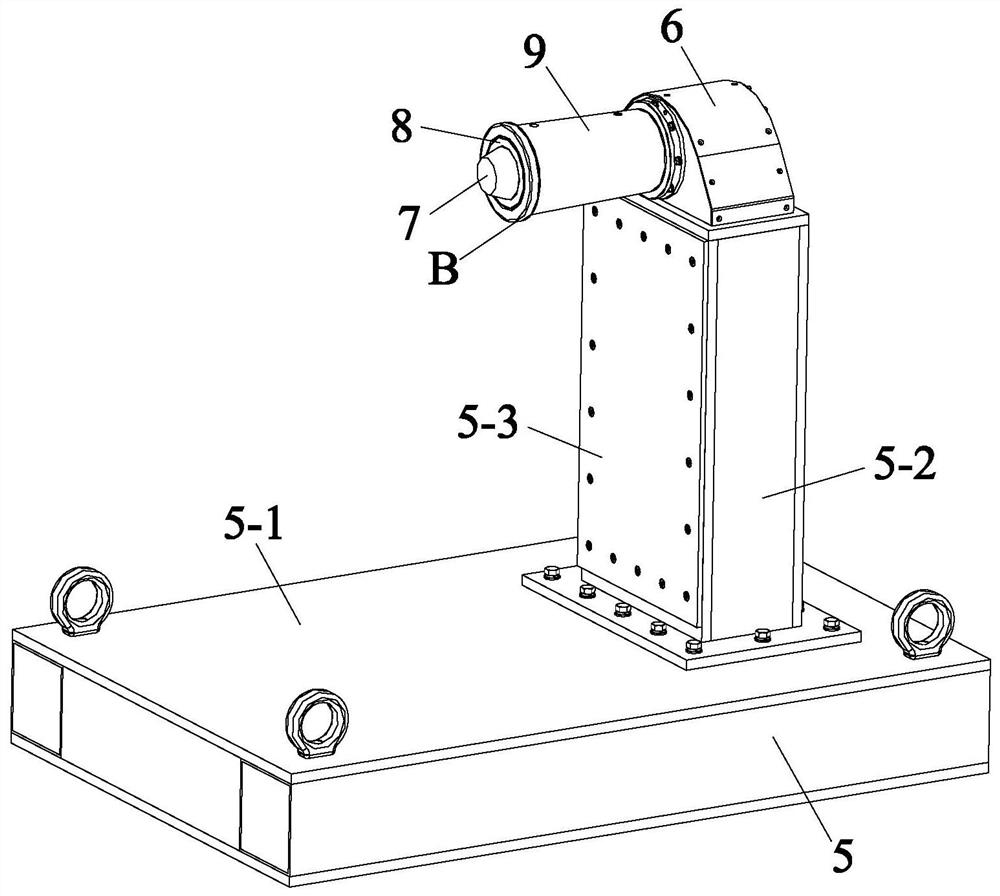

[0019] Such as Figure 3 to Figure 6 As shown, the EMU wheel-mounted brake disc pre-assembly device of the present invention includes a support platform 5, a bearing mechanism 6 and a mandrel mechanism B, and the support platform 5 includes a horizontal base 5-1, a vertical support 5- 2 and the anti-collision pad 5-3, the vertical support 5-2 is vertically connected to the upper end of the horizontal base 5-1, the bearing mechanism 6 is fixed to the top of the vertical support 5-2; the mandrel mechanism B Including a central shaft 7, an inner sleeve 8 and an outer sleeve 9, the axis of the central shaft 7 is parallel to the upper end surface of the horizontal base 5-1, and the second half of the central shaft 7 is inserted into the housing 6 of the bearing mechanism 6 in a horizontal posture -1 inside, the two are connected by bearing rotation; the inner sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com