High-sanitary-standard medicinal container inspection device

A technology for sanitation standards and inspection devices, which is applied in the field of inspection devices for medicinal containers and cans, can solve problems such as low efficiency, time-consuming and labor-intensive, and achieve the effect of improving monitoring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

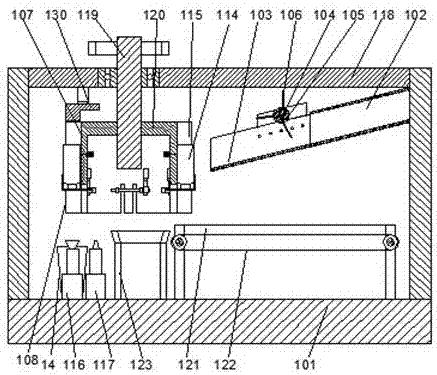

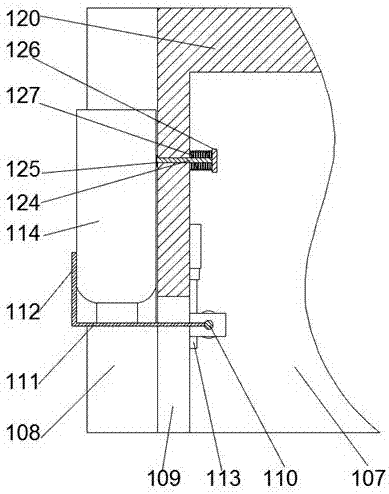

[0034] In this embodiment, in order to facilitate the rotation of the turntable, a preferred structure for driving the turntable to rotate is disclosed. Preferably, an upper cover 118 is arranged above the frame body 101, so that the upper cover is suspended relative to the frame body. A space for processing the tank body is formed between the upper cover and the frame body, and an intermediate shaft 119 is arranged on the upper cover 118, so that the intermediate shaft is connected to the upper cover by bearing rotation, and at the upper end of the turntable 107 The inner side is provided with a table top 120, and the lower end sleeve of the intermediate shaft 119 is arranged on the inner side of the table top 120, so that the table top and the intermediate shaft are fixed to each other. Above the upper cover 118, there is a device for driving the intermediate shaft 119. The rotary driver, when the driver rotates, drives the intermediate shaft to rotate synchronously, and at t...

Embodiment 2

[0036] Due to the light weight of the medicinal container jar, it may fall off from the fastening groove during washing or drying. This embodiment is based on Example 1, in order to avoid the medicinal container jar from flushing or blowing. The bottom moves out from above the fastening groove. Preferably, a pressing plate 130 is arranged above the turntable 107. When the turntable rotates, the lower end surface of the pressing plate is suspended relative to the turntable. A hydraulic device is provided on the lower end surface of the upper cover 118. The hydraulic rod of the hydraulic device is fixedly connected to the upper end surface of the pressure plate 130, so that the pressure rod can slide towards the turntable. The pressure plate 130 is located above the flushing shower head 116 and the blowing nozzle 117. When spraying flushing water into the tank, use the pressure plate to fix the bottom of the tank to keep it stable and prevent it from moving out from the top of th...

Embodiment 3

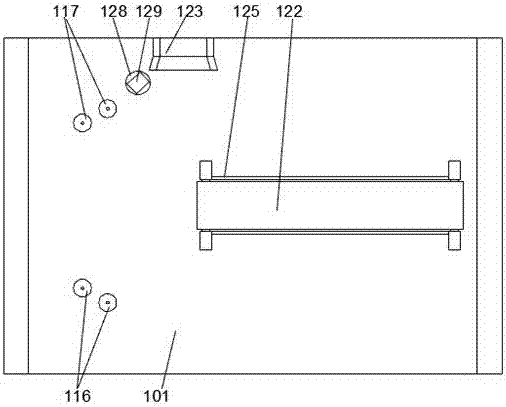

[0038] In this embodiment, in order to facilitate the collection of unqualified tanks, preferably, two shrouds 121 are arranged on the frame body 101 on the side of the through cavity 103, and between the two shrouds 121 A conveyor belt 122 is arranged between them, and the tank body falling from the discharge chute enters the inner side of the coaming plate, and is transported out by the conveyor belt inside the coaming plate for centralized processing.

[0039] In this embodiment, in order to facilitate the collection of tanks after washing, preferably, an external delivery pipe 123 is provided on one side of the frame body 101, and the input end of the external delivery pipe 123 is located at the Below the turntable 107, after the tank body is moved out from the fastening groove, it falls into the external delivery pipe to facilitate directional output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com