Worktable device for workpiece

A workbench and workpiece technology, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of operator raising and lowering adjustment, processing small quantities of workpieces, affecting work efficiency, etc., to achieve easy operation. , The structure is simple, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

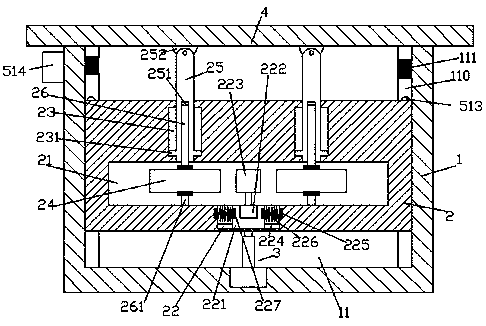

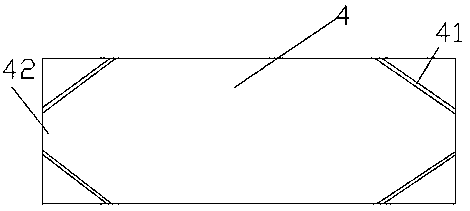

[0018] Such as figure 1 and figure 2 As shown, a workbench device for a workpiece of the present invention includes a processing table 1, a cavity 11 is provided in the processing table 1, and sliding joint grooves 110 are provided on the inner walls of both sides of the cavity 11. A positioning plate 111 is provided at the upper end of the connecting groove 110, and a slide table 2 is arranged in the cavity 11, and both ends of the sliding table 2 are arranged in the sliding connecting groove 110 and slide with the sliding connecting groove 110. The bottom of the slide table 2 is provided with a pushing device 3, the slide table 2 is provided with an assembly cavity 21, and the midpoint of the bottom of the assembly cavity 21 is provided with a placement groove 22, and the assembly cavity 21 The sliding table 2 at the top is provided with a push cavity 23 on the left and right, and a casing 25 is provided in the push cavity 23, and the casing 25 is elongated up and down alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com