Manufacturing tool of packing bags for experiments and manufacturing method of packing bags for experiments

A technology for making tools and packaging bags, which is applied in the field of experimental packaging bag making tools, can solve problems such as uneven glue application, affecting the quality of high-temperature-resistant packaging bags, and unevenness, so as to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

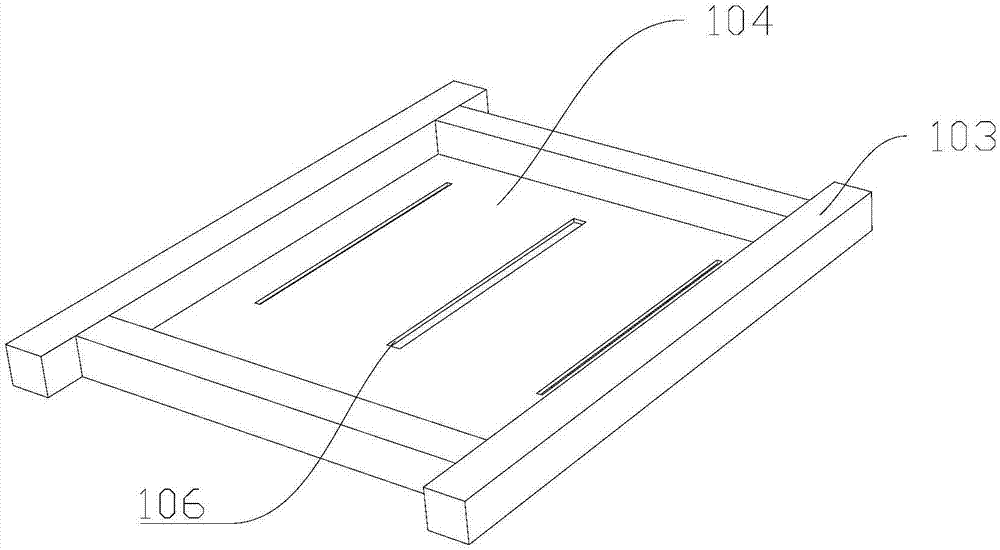

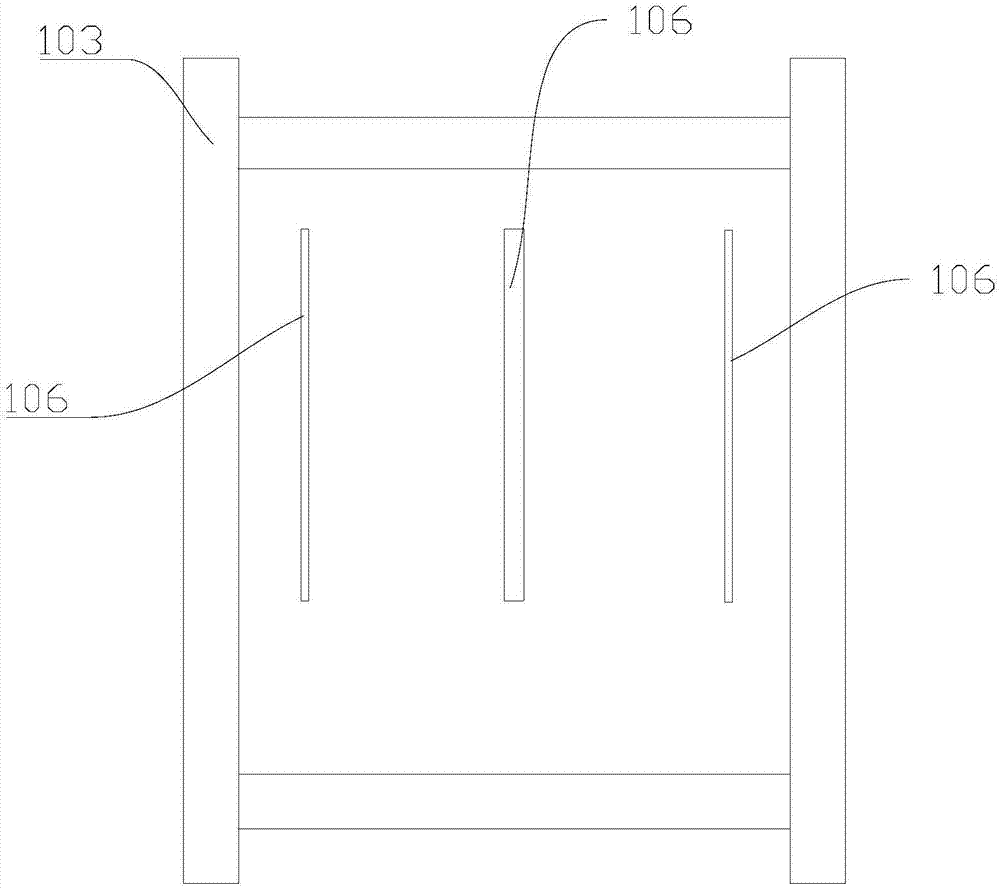

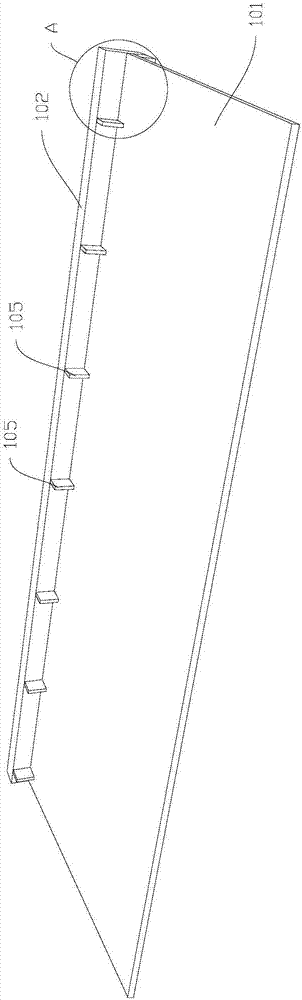

[0036] see Figure 1 to Figure 5 As shown, Embodiment 1 of the present invention provides a packaging bag making tool for experiments, including a painting tray, a panel 101 and a chassis 102, and the panel is installed on the chassis 102; the painting tray includes a tray frame 103 and a brush plate 104 , the brush plate is installed in the frame of the tray frame 103; the brush plate is provided with a plurality of leakage holes arranged at intervals.

[0037] Specifically, the tray frame 103 is rectangular; the brush plate is detachably connected to the tray frame 103, which facilitates the replacement of the brush plate; the panel is supported by the bottom frame 102, and one long side of the bottom frame 102 has a limit block 105, A gap is formed between the stopper 105 and the top frame of the underframe 102, and the panel is limited in the gap. On the one hand, the position of the panel can be positioned, and on the other hand, it is also beneficial to the positioning o...

Embodiment 2

[0052] The experimental packaging bag making tool in this example is an improvement on the basis of Example 1. The technical content disclosed in Example 1 will not be described repeatedly, and the content disclosed in Example 1 also belongs to the content disclosed in Example 2.

[0053] see Image 6 As shown, in this embodiment, a scale 108 is fixed on the lower surface of the transparent panel. The scale 108 is a straight edge or a square square.

Embodiment 3

[0055] The experimental packaging bag making tool in this example is an improvement on the basis of Example 1 or Example 2. The technical content disclosed in Example 1 or Example 2 will not be described repeatedly. The content also belongs to the content disclosed in the third embodiment.

[0056] In this embodiment, a lifting positioning corner is installed on the panel for positioning the bag-making film placed on the upper surface of the panel.

[0057] see Figure 7 to Figure 10 As shown, specifically, the lifting and lowering positioning corner includes a telescopic corner 109, a base 110 and a spring 111; one end of the spring 111 abuts against the bottom end surface of the telescoping corner 109, and the other end of the spring 111 abuts against the bottom of the cavity of the base 110 Then, the spring 111 is located in the cavity of the base 110; A corner hole is opened on the panel, and the telescopic corner 109 is penetrated in the corner hole, and the base 110 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com