An external heating device for manufacturing led straight tube lamps

A LED straight tube lamp and external heating technology, which is applied to mechanical equipment, devices for coating liquid on the surface, connecting components, etc., can solve the problems of affecting the appearance, reducing the service life of hot melt adhesive, and the limited effect of magnetic connection, etc. Achieve the effect of optimizing design and use, avoiding reliability decline, and avoiding electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention, in a glass tube, we propose a novel LED lamp straight tube, in order to solve the problems mentioned in the background art and the problems described above. For the above objects, features and advantages of the present invention can be more fully understood by reading the following detailed description of the drawings Specific embodiments of the present invention binds. The following description of embodiments of the present invention is only illustrative for purposes of illustration and do not represent embodiments or to limit the invention to the particular embodiment all of the embodiments of the present invention.

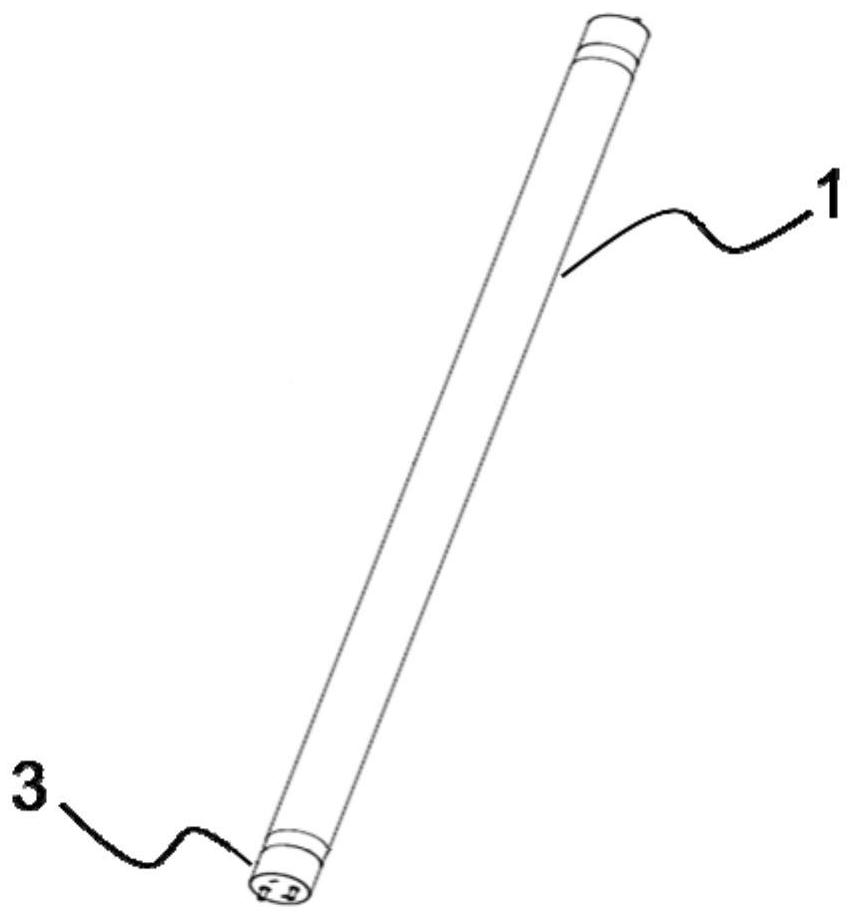

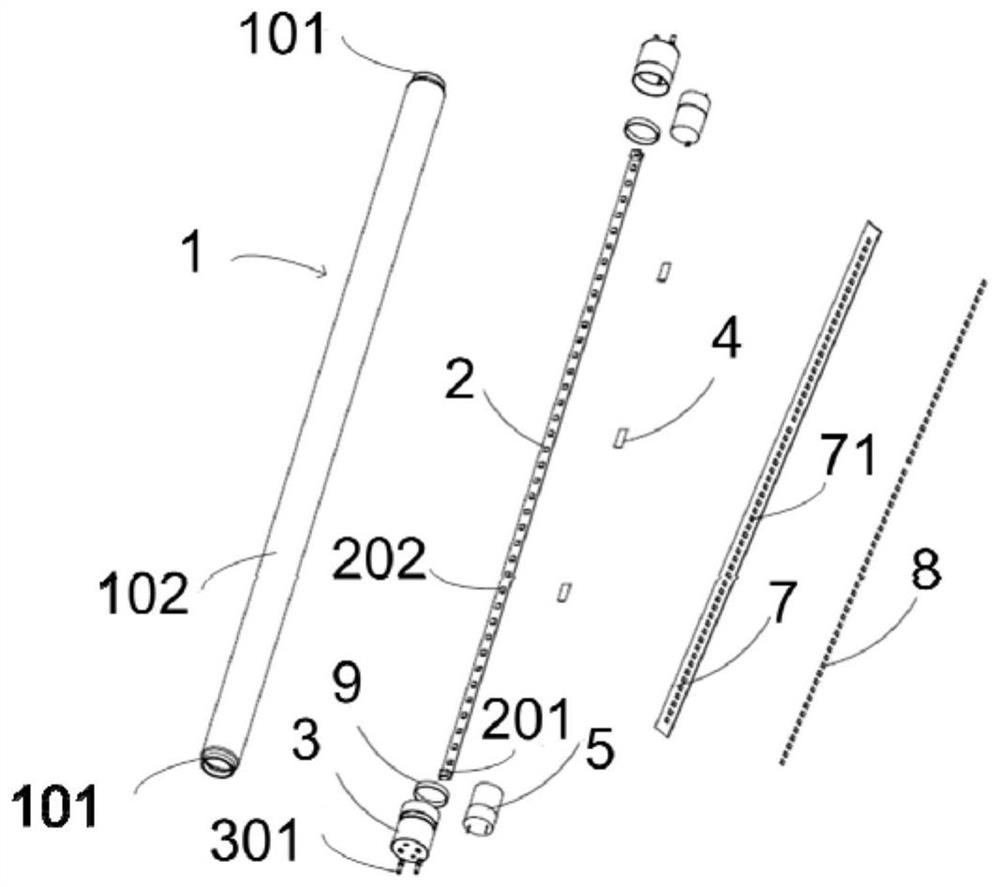

[0087] Please refer to figure 1 and figure 2 , In the embodiment of the present invention provides an LED lamp a straight tube embodiment, which comprises: a lamp tube 1, a lamp disposed within the tube plate 12, and the cap 3 are provided on the two ends of the tube 1. Lamp tube 1 may be plastic or glass tube, the size of the base is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com