Immersion-type automatic generation method for 3D (Three-dimensional) factory map, electronic equipment and storage medium

An automatic generation and immersive technology, applied in 3D modeling, image data processing, instruments, etc., can solve the problems of labor and time cost, 3D factory map cost, labor and time cost, etc., to save labor and time. Time cost, the effect of improving operational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

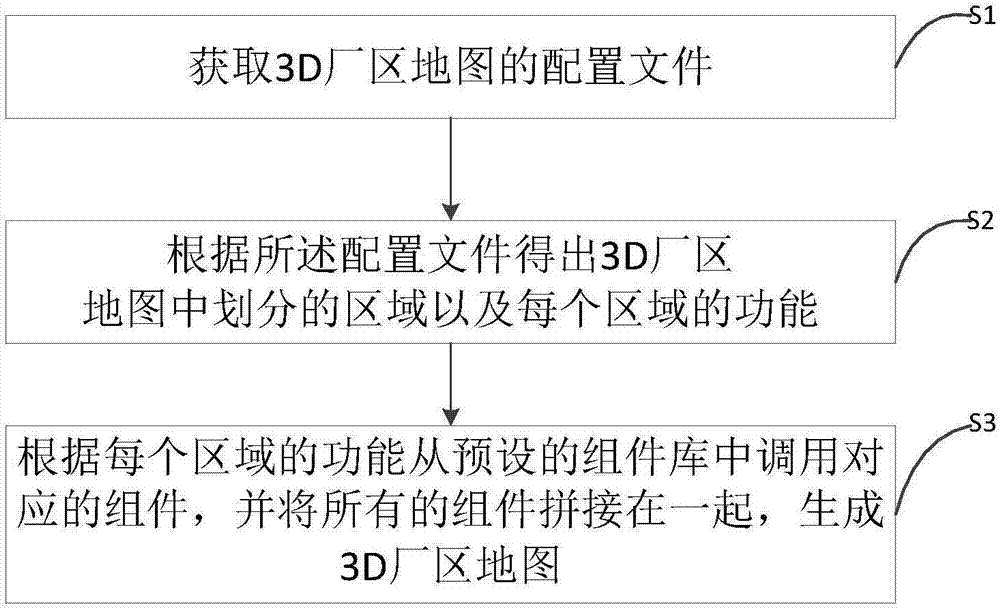

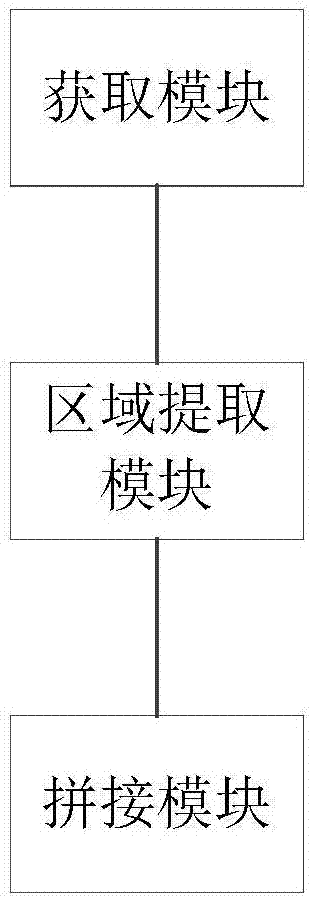

[0036] In order to solve the above-mentioned technical problems, the present invention makes the following design: the factory map is considered to be composed of multiple components of the same type or different types. The components include material maps and models, and the model refers to the attribute information such as the size, shape, and position of the component, which is equivalent to the model components in the 3D factory map; and the material map refers to the corresponding colors, icons, patterns, etc. on the model. . For example, for a street lamp, in a 3D large-scale factory model, the frame of the street lamp is the model, and the colors and patterns on the street lamp are material maps.

[0037] Before generating the factory map, first establish a component library, which is a collection of various components that have different functions and have a hierarchical structure that make up the factory map. For example, for a car model, it may include car cover comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com