A spark plug with a heated ignition chamber

An ignition chamber and spark plug technology, applied in the field of spark plugs, can solve the problems of limited improvement of fuel economy and inability to effectively reduce the lean limit of combustible mixture, and achieve the effects of improving fuel economy, increasing lean burn limit and reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

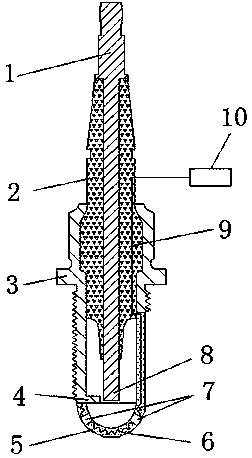

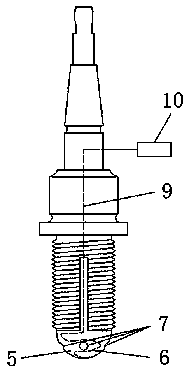

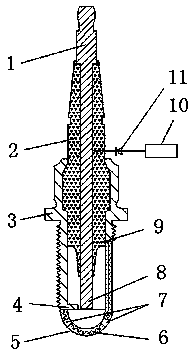

[0015] figure 1 , 2 A block diagram of a spark plug with a heated ignition chamber is shown. In the figure, the spark plug with a heated ignition chamber includes a positive pole terminal 1, an insulator 2, a spark plug body 3, an ignition chamber housing 5, a center electrode 8, a heating wire 6, a heating controller 10 and a one-way conducting element 11. The inner side of the lower end of the spark plug body 3 is provided with a grounded negative electrode 4 , and the lower end is fixedly connected to an ignition chamber housing 5 provided with one or more injection holes 7 . The center electrode 8 is wrapped by the insulator 2 and arranged at the center of the spark plug body 3 . There is an ignition gap between the lower end of the center electrode 8 and the grounded negative electrode 4 , and the positive pole terminal 1 is arranged at the upper end. A heating wire 6 is embedded in the wall of the ignition chamber housing 5, one end of the heating wire 6 is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com