Novel Chinese cabbage combine harvester

A technology of combine harvester and Chinese cabbage, which is applied in the fields of harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of low work efficiency and high labor intensity of Chinese cabbage, save manpower, reduce labor intensity, and be widely popularized and applied. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

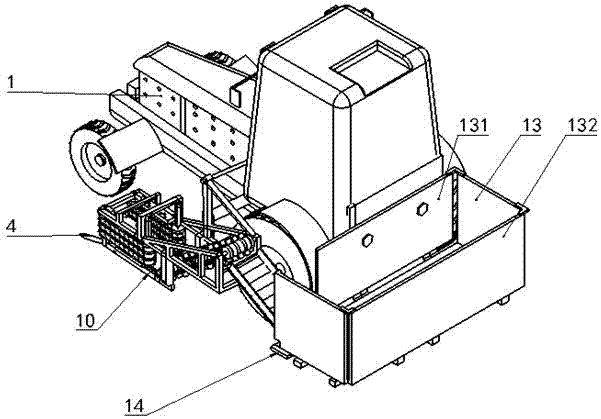

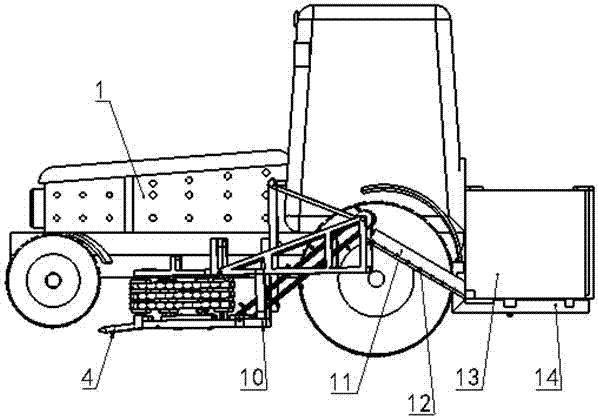

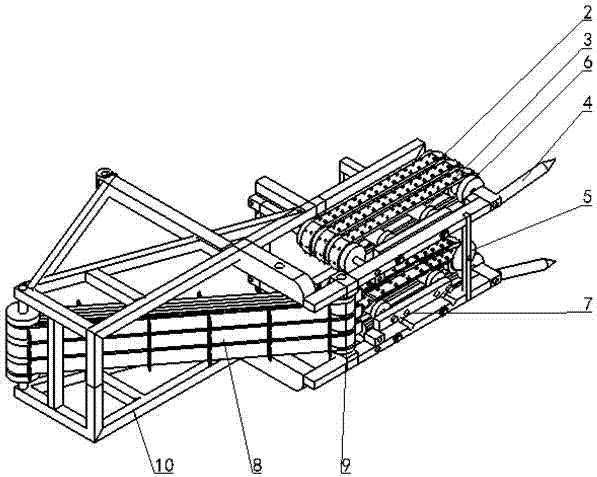

[0034] In order to clearly illustrate the technical features of the solution, the solution will be described below in conjunction with the accompanying drawings and specific implementation methods.

[0035] Refer to attached Figure 1-8 , a new type of Chinese cabbage combine harvester The specific embodiment: it includes a traction device 1 and a frame 10 on the upper side of the traction device 1, and the frame 10 is driven by the traction device 1 to move along the direction of harvesting cabbage. The frame 10 is also equipped with a conveying mechanism, a guide mechanism 4 and a root-cutting mechanism 5, and devices such as a transmission system, a power system, and a control system provided inside will not go into details here, and can be realized by existing technologies. The conveying mechanism includes a group of vertically arranged front belt conveyors 2 and a rear belt conveyor 8 with channels left, and the root cutting mechanism 5 is arranged at the bottom of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com