Reciprocating lever conveyor line

A reciprocating rod and conveying line technology, which is applied in the field of reciprocating rod conveying lines, can solve problems such as workpiece deformation, achieve the effect of avoiding deformation and improving the conveying tempo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

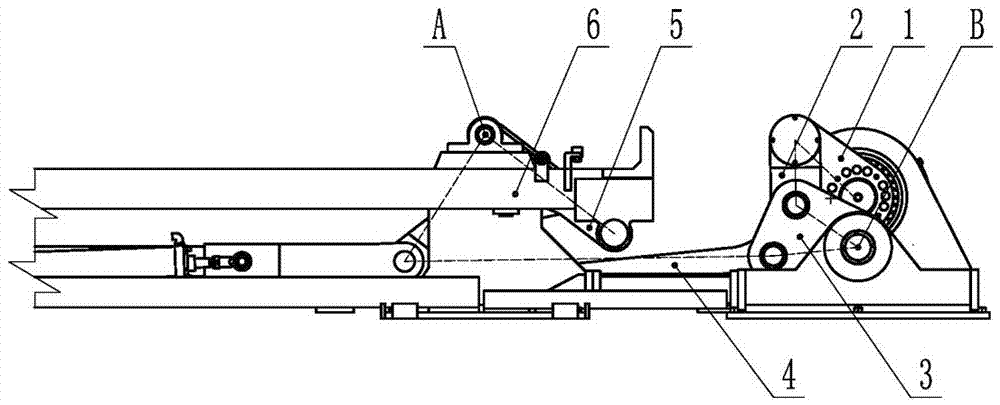

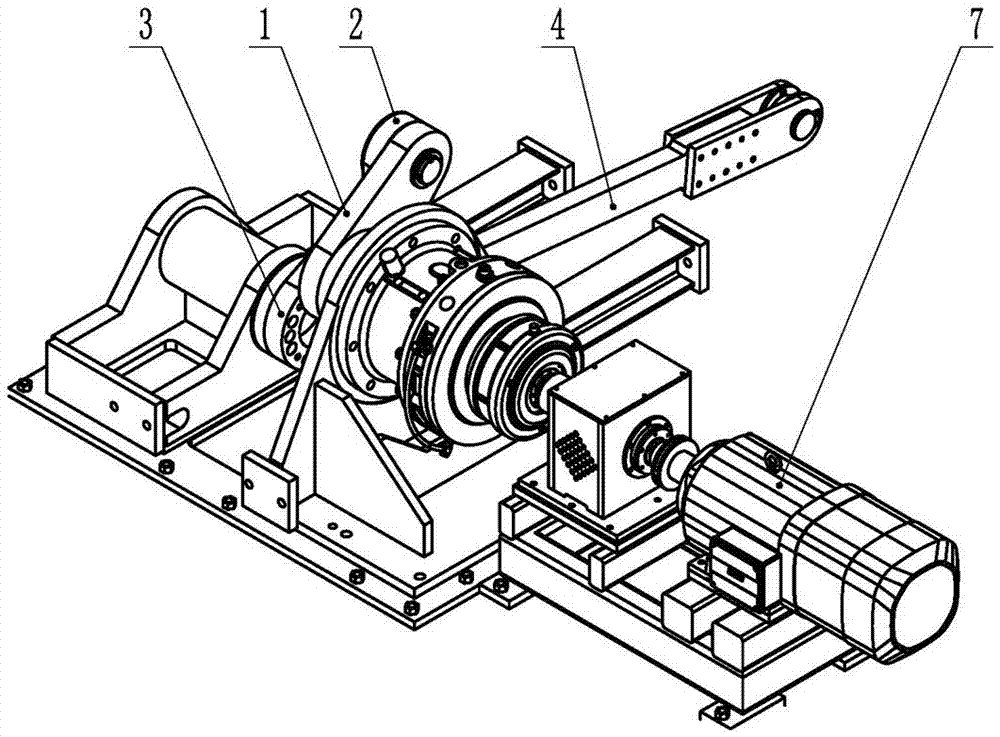

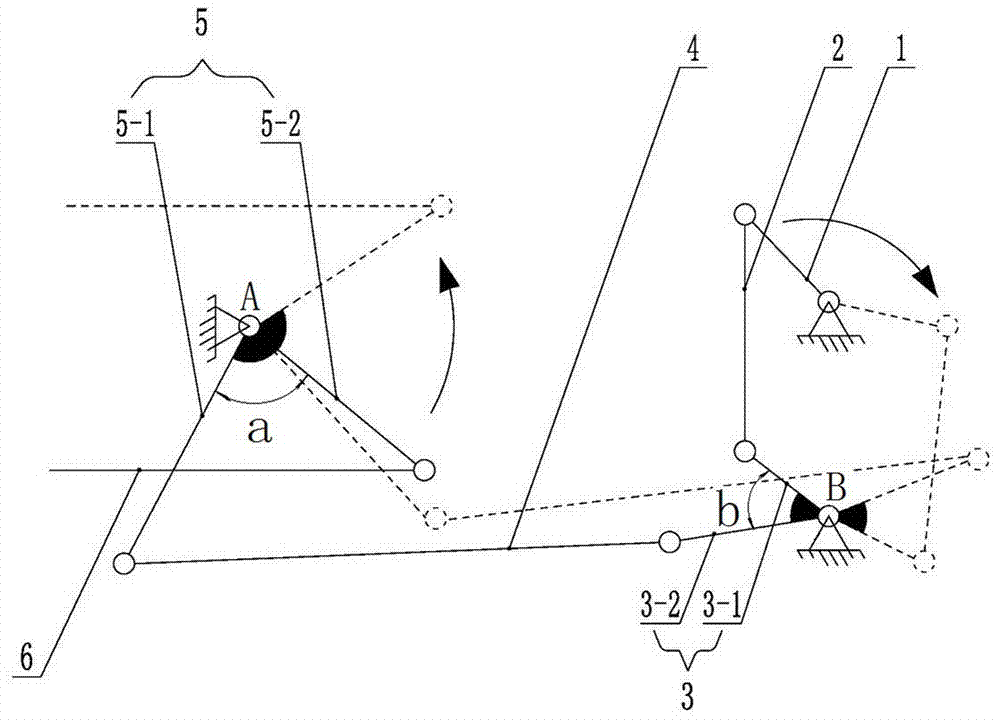

[0014] Such as figure 1 , figure 2 and image 3 The shown reciprocating rod conveying line includes a reciprocating rod bracket 6, and the reciprocating rod bracket 6 is connected to the drive motor 7 through a multi-link lifting unit. The multi-link lifting unit in this embodiment is a six-link lifting unit; The connecting rod lifting unit includes a swing arm 1 arranged on the output shaft of the drive motor 7, one end of the swing arm 1 is set on the output shaft of the drive motor 7 through an expansion sleeve, and the other end of the swing arm 1 is connected by a roller bearing and a short pull rod. One end of 2 is hinged; the other end of the short pull rod 2 is hinged with one end of the upper triangular link 3-1 of the triangular connecting rod 3 through an outer spherical roller bearing, and the triangular connecting rod 3 includes one end hinged on the hinge shaft IIB at an angle b The set triangle upper link 3-1 and the triangle lower link 3-2, the angle b betwe...

Embodiment 2

[0016] The angle b between the triangle upper link 3-1 and the triangle lower link 3-2 is 35°, the angle a between the lift lower link 5-1 and the lift upper link 5-2 is 65°, and the other features Same as Example 1.

Embodiment 3

[0018] The angle b between the triangle upper link 3-1 and the triangle lower link 3-2 is 45°, the angle a between the lift lower link 5-1 and the lift upper link 5-2 is 75°, and the other features Same as Example 1.

[0019] When working, the workpiece is placed on the process positioning, and the drive motor 7 rotates forward at a uniform speed to drive the swing arm 1, the swing arm 1 drives the short tie rod 2, the short tie rod 2 drives the triangular connecting rod 3, and the triangular connecting rod 3 drives the long pull rod 4, and The lifting swing arm 5 connected with the long pull rod 4 drives the reciprocating rod bracket 6 to perform a vertical variable-speed upward movement. When the reciprocating rod bracket 6 rises to 200mm, it contacts the workpiece. workpiece, so that the impact on the workpiece is small, the reciprocating rod bracket 6 will accelerate the movement after contacting the workpiece, and improve the conveying rhythm. When the workpiece is trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com