Geotechnical engineering supporting structure model test device and test method thereof

A model test device and a technology for supporting structures, which are applied in the testing of machine/structural components, measuring devices, and elasticity testing, etc., can solve the problems of less research on the optimization of supporting schemes and less research on optimization, and achieve easy The effect of grasping, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

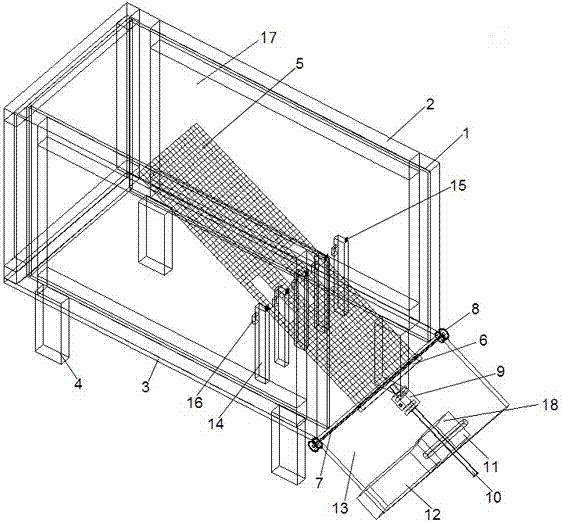

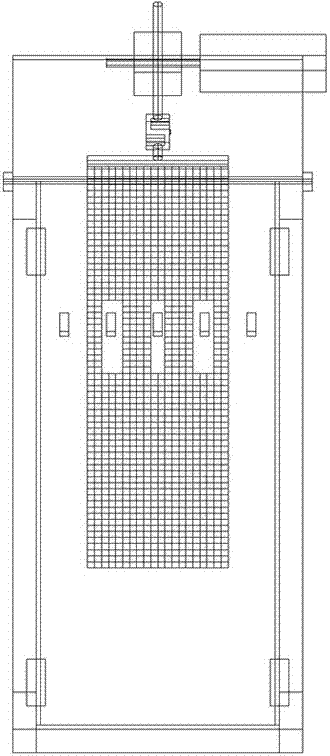

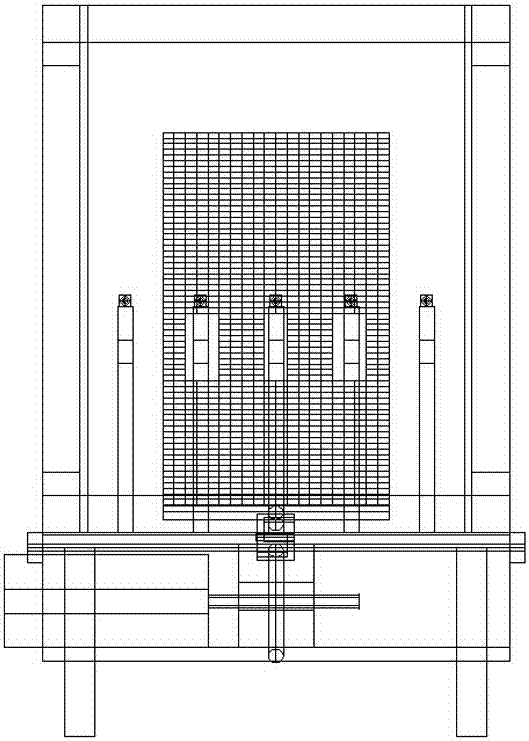

[0044] A geotechnical engineering support structure model test device, including a model box 17, a support structure 14, a traction model system 18, a sliding belt model 5 and a measurement system, the model box 17 is filled with soil, and the model box 17 is provided with a sliding belt model 5, the front end of the sliding belt model 5 is connected with the traction model system 18, the front end of the sliding belt model 5 is connected with the traction model system 18, the model box 17 is a cuboid with top and front openings, and the supporting structure 14 wears The opening on the sliding belt model 5 is inserted into the soil, and the measurement system is installed on the support structure 14 and one side of the model box 17 .

[0045] The model box 17 also includes a base plate 3, the plexiglass plate 1 and the iron frame 2 are vertically installed on the base plate 3, the plexiglass plate 1 is installed on the inside of the iron frame 2, and the front end of the base p...

Embodiment 2

[0063] This embodiment is basically the same as Embodiment 1, the difference is:

[0064] In this embodiment, the method of laying piles for the support structure 14 is changed from straight-line piles to broken-line piles, that is, under the condition that the shape of the slope body and the traction speed of the motor are kept unchanged, it is necessary to study the traction-type landslide in the broken-line pile arrangement support structure. In the case of 14, the change law of slope stress-strain, surface shape and pressure, combined with Example 1, can be used to compare and study the evolution law of slope stress-strain under different pile arrangements, so as to achieve support under different pile arrangements. preferred purpose.

Embodiment 3

[0065] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is:

[0066] In this embodiment, the support structure 14 is changed from pile support to anchor support 20, that is, under the condition that the shape of the slope body and the traction rate of the motor are kept constant, the situation of the traction landslide in the anchor support 20 is studied. The stress-strain, surface morphology, and pressure changes of the downslope, combined with Example 1, can be used to compare and study the stress-strain evolution of the slope under different support types, so as to achieve the purpose of support optimization under different support types.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com