Pneumatic gear shifting control device and gear shifting control method of automated mechanical transmission

A technology of automatic transmission and pneumatic shifting, applied in the direction of transmission control, fluid pressure actuating device, mechanical equipment, etc., to achieve the effect of simple and reliable control, simple structure, and convenient installation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

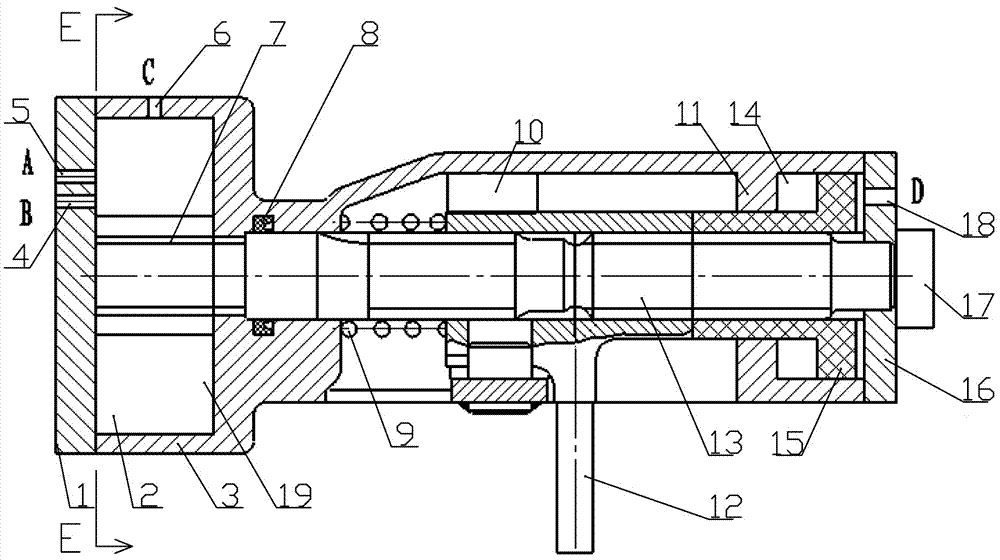

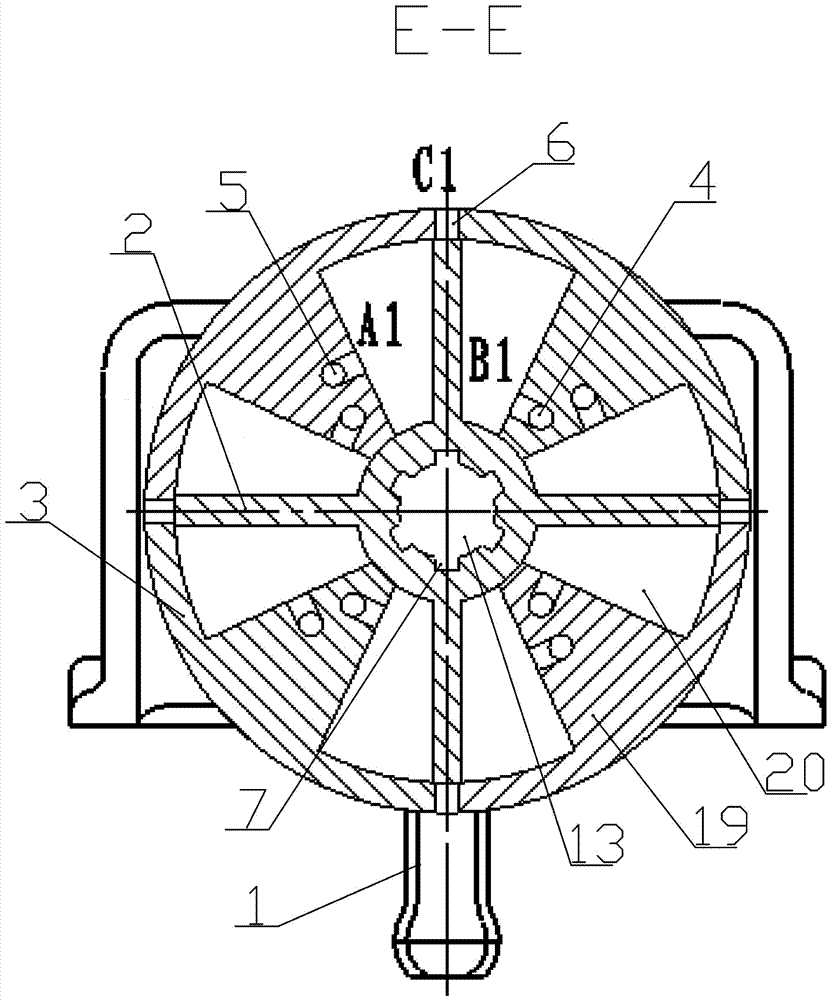

[0036] Such as Figure 1-5 As shown, a pneumatic shift control device for a mechanical automatic transmission includes a shift cylinder housing 3, a shift shaft 13 is installed inside the shift cylinder housing 3, and one end of the shift shaft 13 is provided with a useful The rotary gear shifting mechanism is used for gear shifting, and the other end is provided with a pneumatic gear selecting mechanism for gear selection; a shift dial 12 is installed on the shift shaft 13 .

[0037] Further, the rotary shifting mechanism includes a rotor piston 2, which is sleeved on the end of the shift shaft 13 through a spline 7, and the rotor piston 2 is connected to a plurality of parts on the head of the shift cylinder housing 3. Cylinders 19 are matched, and the cylinders 19 are uniformly arranged on the head of the shift cylinder housing 3, and a plurality of sealed fan-shaped shift cavities 20 are formed between the plurality of cylinders 19. The outer end surface of the body 19 is...

Embodiment 2

[0050] The gear shift control method adopting any one of the pneumatic gear shift control device of the mechanical automatic transmission comprises the following steps:

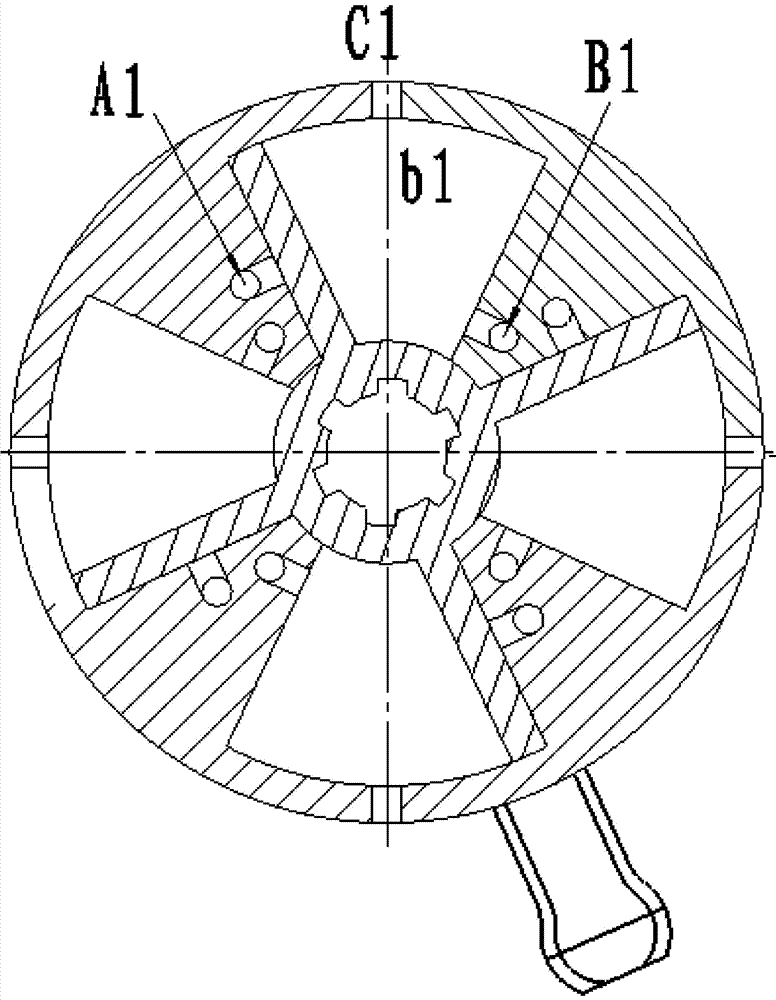

[0051] Step1: When working, the cylinders of the four cylinder blocks 19 participate in the work at the same time, taking the No. 1 cylinder as an example;

[0052] Step2: Shift from first gear to second gear. Initially, the shift knob 12 is in the first and third gear positions. At this time, the working chamber a1 of the fan-shaped shift chamber 20 is the smallest, and the working chamber b1 is the largest; the electromagnetic valve is controlled to make the A1 port intake, Port B1 is exhausted and port C1 is closed. At this time, the working chamber a1 of the No. 1 cylinder intakes air, and the working chamber b1 exhausts. Drive the shift shaft 13 to rotate, and the shift shaft 13 drives the shift dial 12 to rotate clockwise to the right to complete the action of shifting to the second gear. At this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com