A direction adjusting device for laying cables

A direction adjustment and cable technology, applied in the direction of cable laying equipment, etc., can solve the problems of dead knots, failure of carrying, and tangled cables, so as to improve work efficiency, ensure work efficiency, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

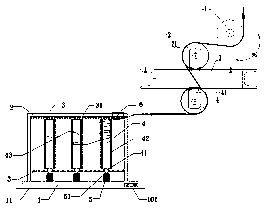

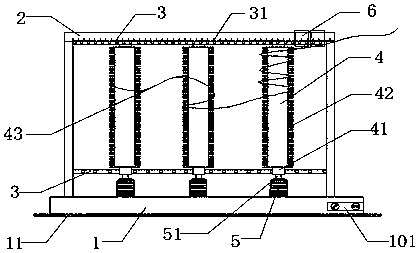

[0032] Example 3 see Figures 1 to 5 , on the basis of Embodiment 1, Embodiment 2 and Embodiment 3, the following is a detailed description of the tensioning direction wheel in a direction adjustment device for laying cables of the present invention, specifically a direction adjustment for laying cables The device includes a box body 1, and at least one volume control wheel is installed in the box body 1. In this embodiment, a carding volume control wheel consisting of three volume control wheels is preferred. Specifically, the combing control wheel includes a chassis 1, a support body 2, a control wheel 4, a slideway 3, and a working motor 5. The support body is a square frame structure, and is arranged on the top of the chassis 1, and the top of the support body 2 The cable-winding detection head 6 is socketed, the slideway 3 is arranged on the upper and lower symmetrical positions of the support body 2, and several control wheels 4 are arranged in the vertical direction bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com