Circulating peeling and cleaning mechanism

A cleaning mechanism and circulating technology, applied in the field of machinery, can solve the problems of high cost, low efficiency and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the improvement made by the present invention compared with the prior art, the specific embodiments of the present invention will be described in detail below.

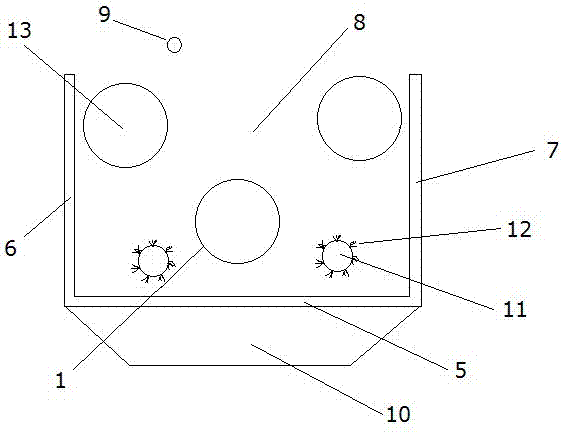

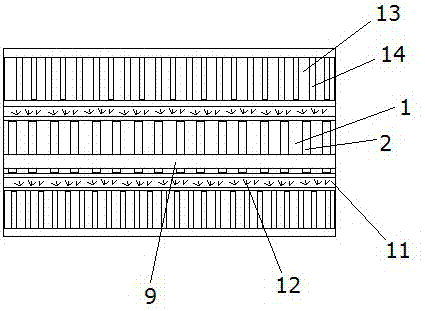

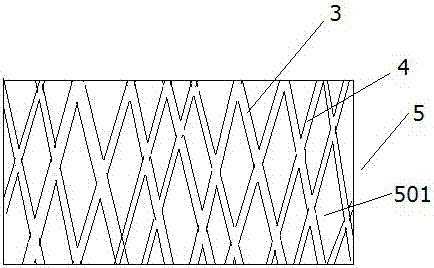

[0021] Such as figure 1 As shown, the circulation type peeling and cleaning mechanism includes a driving shaft 1, and on the driving shaft 1, a groove 2 is spirally wound from left to right, and the depth D of the groove 2 is 0.3~0.5cm, corresponding to The distance L between the adjacent grooves 2 is 1~1.5cm; it also includes a sawtooth bar 15, which is embedded in the groove 2, from Figure 4 It can be clearly seen that the sawtooth bar 15 includes a base 1501 and sawtooth 1502. When embedded, the base 1501 is inserted into the groove 2, and the sawtooth 1502 is exposed outside, and the sawtooth bar 15 moves along the groove 2 from spirally wound on the surface of the driving shaft 1 from left to right, such as figure 2 As shown, the surface of the driving shaft 1 is spirally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com