Disc type rotor craft

A rotorcraft and aircraft technology, applied in the field of aviation aircraft, can solve problems such as difficult control, poor anti-interference ability, and drop in lift, and achieve the effects of enhanced thrust or lift, strong anti-interference ability, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

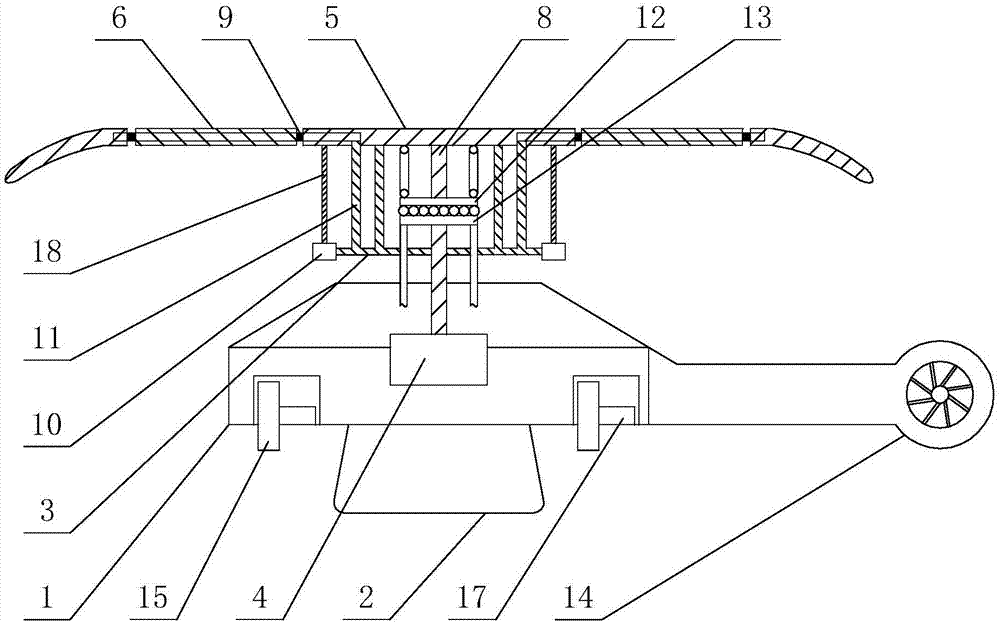

[0033] A dish rotorcraft, such as figure 1 Shown, comprise fuselage 1, rotor system and landing gear 2, described rotor system and landing gear 2 are respectively arranged on the upper and lower parts of fuselage 1, control room and engine 4 are established in fuselage 1, and this aircraft also includes control system ;

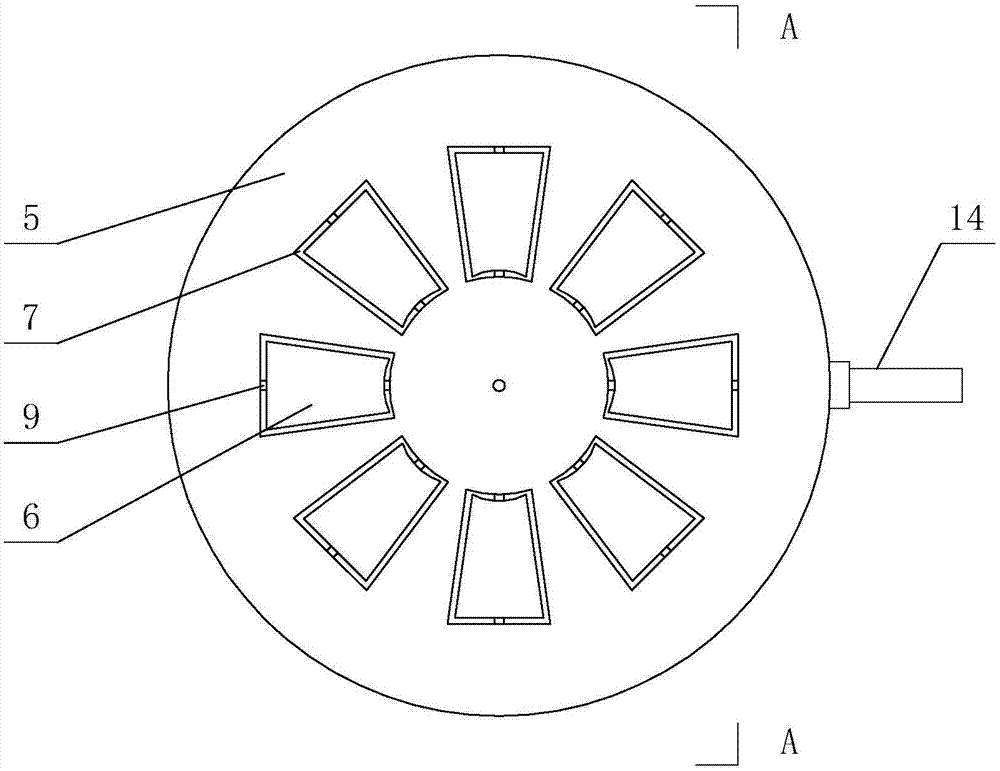

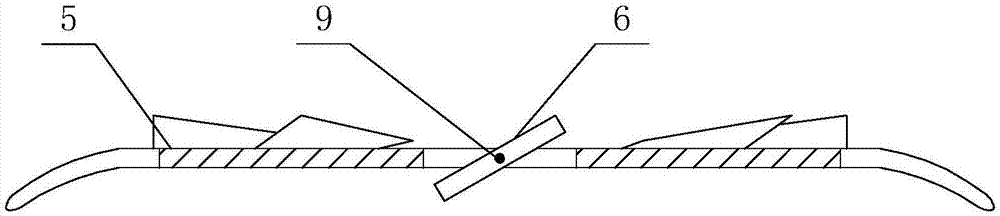

[0034] Such as figure 1 , figure 2 As shown, the rotor system includes a disc rotor 5 and a movable rudder surface 6, the disc rotor 5 is dish-shaped, and its upper surface is uniformly provided with rudder surface openings 7 of the same shape and size as the movable rudder surface 6, The middle part of the bottom surface of the disc rotor 5 is connected to a central shaft 8 in rotation, and the other end of the central shaft 8 is connected to the transmission system of the engine 4. There are 8 movable rudder surfaces, which are respectively embedded in the rudder surface openings 7, and each movable rudder surface 6 The middle part traverses a rotating ...

Embodiment 2

[0042] A dish rotorcraft, its structure is basically the same as that of Embodiment 1, the difference is that there are 2 to 6 movable rudder surfaces, and the corresponding rudder surface control panels are connected to the rotating shaft through 2 to 6 connecting rods, There are 2 ducted propellers, which are located on both sides of the aircraft.

Embodiment 3

[0044] A kind of disc rotorcraft, its structure is basically the same as embodiment one or embodiment two, the difference is that, as Figure 6 As shown, the aircraft also includes a coaxial anti-propeller rotor 19, which replaces the balanced propeller 14 in the above-mentioned embodiment one and embodiment two. The upper part of the rotor 5 constitutes a coaxial anti-paddle type with the disc rotor 5, and the direction of rotation is opposite so as to offset the reaction force produced by the rotation of the disc rotor and stabilize the fuselage.

[0045] Action process:

[0046] ①Take off:

[0047] The engine 4 starts, the central shaft 8 rotates, the disc rotor 5 rotates horizontally, the movable rudder surface 6, the rudder surface control mechanism and the moving disk 12 of the automatic tilter rotate together, the fixed disk 13 is fixed, and the control room issues instructions , the rudder surface drive motor 10 drives the rudder surface control panel 3, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com