Device for collecting cable

A wire take-up device and cable technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, thin material handling, etc., can solve the problems of unstable take-up tension, irregular winding, and cable shaking, etc., and achieves simple structure, The effect of neat and flexible collection of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below:

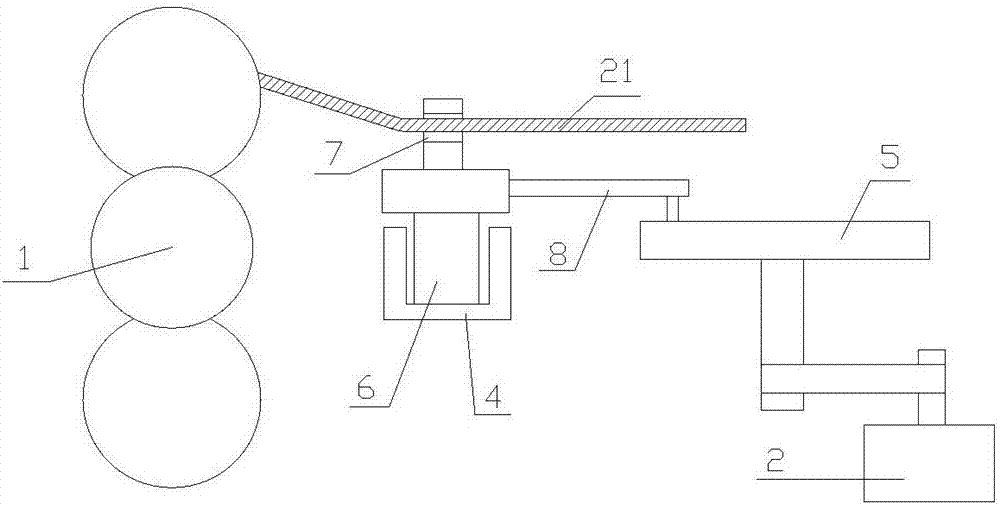

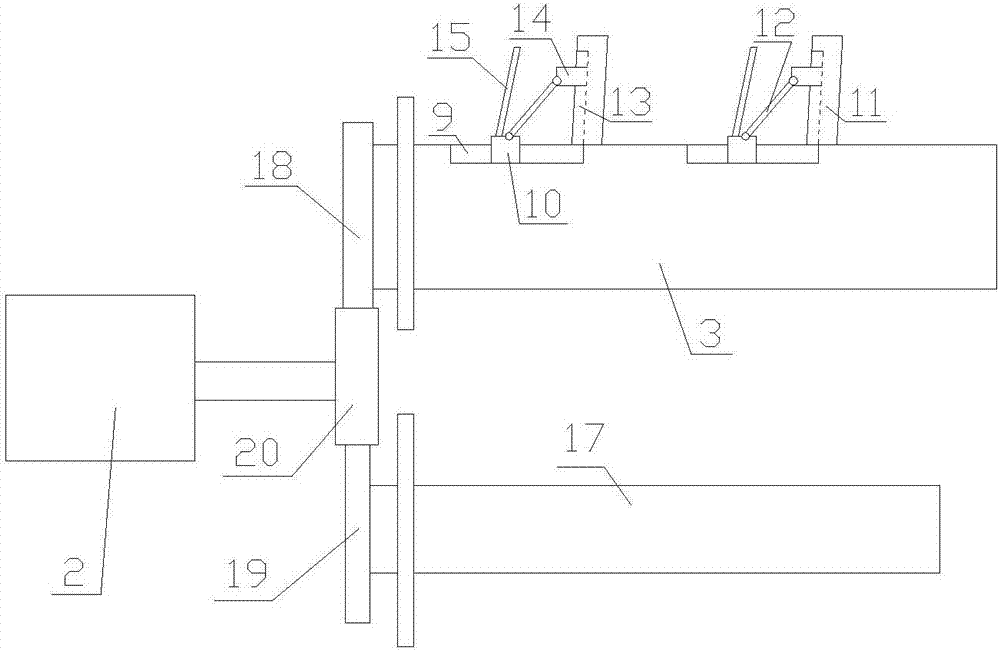

[0032] combine figure 1 , 2 , 3: A device for collecting cables, including a wire take-up device, the wire take-up device includes a first motor 1, a second motor 2, a first bobbin 3, and the first motor 1 and the first bobbin 3 drive connect;

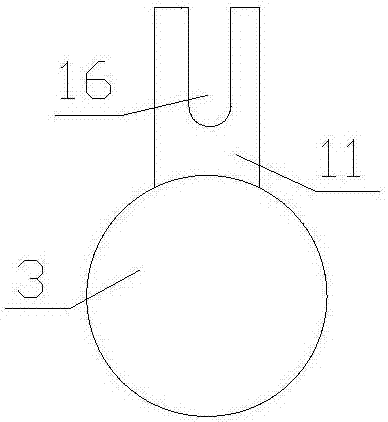

[0033] One side of the first reel 3 is provided with a first chute 4 and a turntable 5, the first chute 4 and the axial direction of the first reel 3 are oblique or parallel, and are arranged in parallel in this embodiment; the first A first sliding block 6 is provided in the chute 4. The first sliding block 6 is provided with a through hole 7 that allows the cable 21 to pass through. The first sliding block 6 is connected to the edge of the turntable 5 through a connecting rod 8. The turntable 5 is used to drive the first sliding block 6 to move back and forth along the extending direction of the first chute 4 , and the turntable 5 is drive-connected with the second motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com