A pressure testing device and pressure testing method for evaluating road surface smoothness

A pressure testing and flatness technology, applied in the direction of roads, roads, road repair, etc., can solve the problem of few dynamic detection methods, and achieve the effects of vibration uniformity control, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

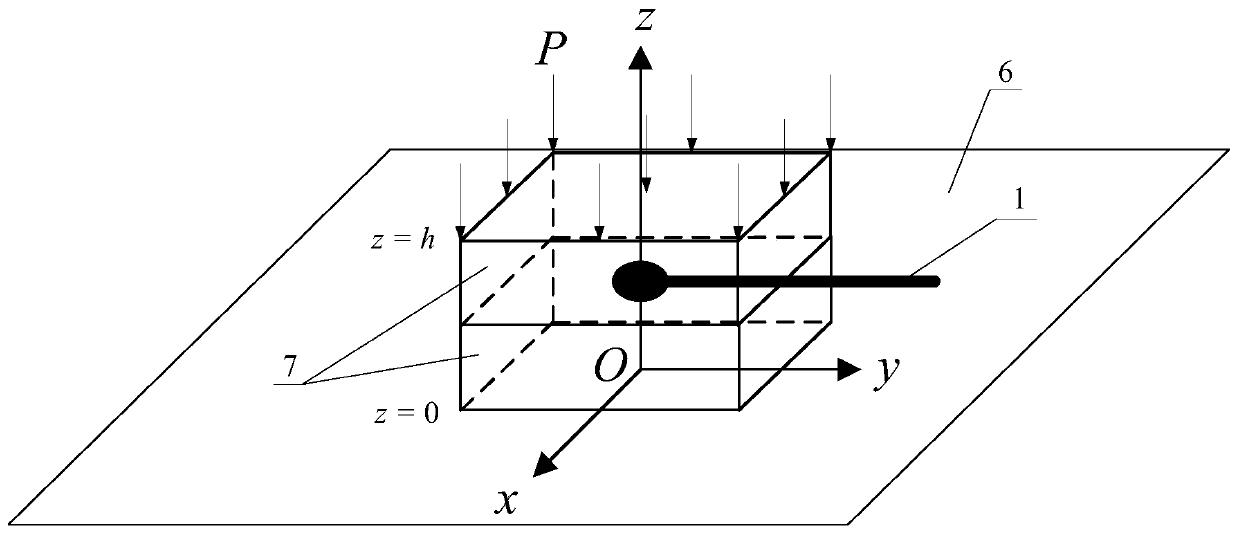

[0022] (1) Principle of stress test

[0023] According to the principle of elastic mechanics, the force of the rubber pad adopts the model of semi-infinite space body subjected to uniform load. Such as figure 1 As shown, the rubber pad is subjected to uniformly distributed unit area pressure P on the horizontal boundary of the rubber pad, the total height h of the two layers of the same rubber pad, and the horizontal deformation boundary condition u x = u y =0, the boundary condition u of the vertical deformation variable on the ground z = u h =0. Since only the deformation in the vertical direction (Z direction) is considered, when the depth of the sensor probe in the rubber pad is z, the deformation and stress of the rubber material at the probe position are respectively:

[0024]

[0025]

[0026] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com