An Efficient Dust Monitoring System in Factory Workshop

A technology of monitoring system and dust detection device, which is applied in the direction of measuring device, suspension and porous material analysis, scientific instruments, etc., can solve the problems of large number of casualties, no effective monitoring measures for dust in the workshop, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described in conjunction with the following examples.

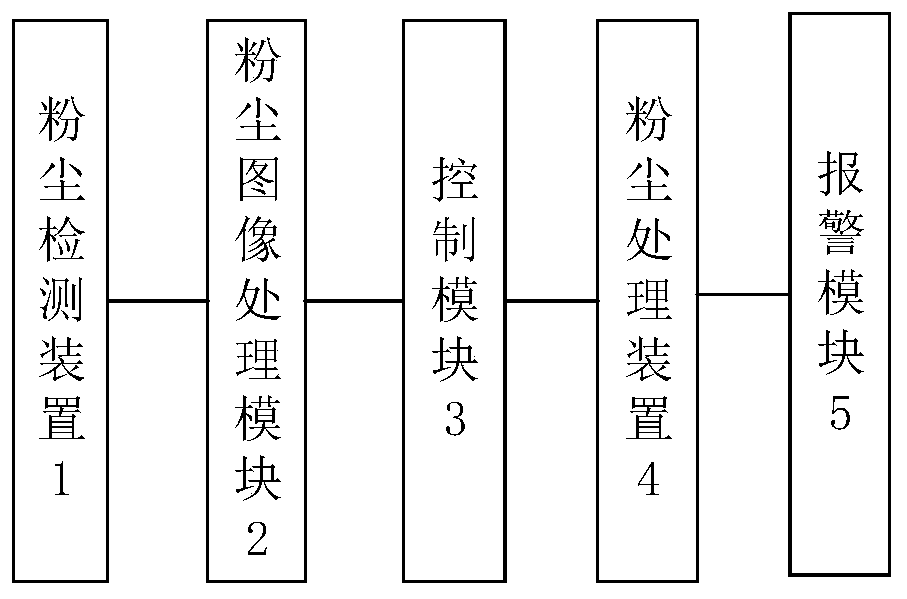

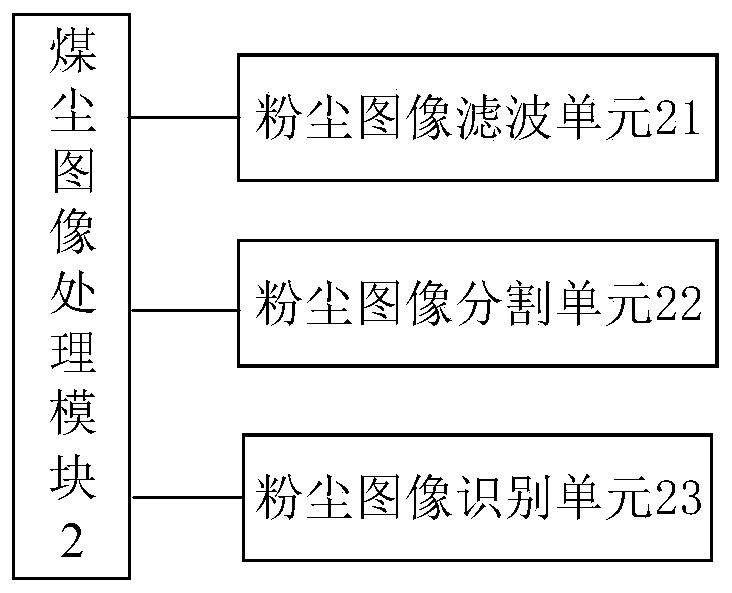

[0013] see figure 1 and figure 2 , a kind of high-efficiency factory floor dust monitoring system of the present embodiment, comprises dust detection device 1, dust image processing module 2, control module 3, dust processing device 4 and alarm module 5, and described dust detection device 1 is a rotatable camera , for collecting dust images in the workshop, the dust image processing module 2 is used for processing, segmenting and identifying the dust images, thereby calculating the dust content in the workshop, when the dust content in the workshop exceeds the standard, the alarm module 5 to give an alarm, and use the dust processing device 4 to process the dust in the workshop. The control module 3 is installed in the monitoring room and is used to control the dust detection device 1, the dust processing device 4 and the alarm device 5.

[0014] Preferably, the alarm device 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com