Cooling liquid for diamond wire cutting circulation system and preparation method and use method thereof

A diamond wire and circulation system technology, applied in the petroleum industry, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of large fluctuations in the yield rate of cutting workpieces, difficult concentration indicators, and difficult control of recycled water quality indicators. Achieve the effect of easy index detection and quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

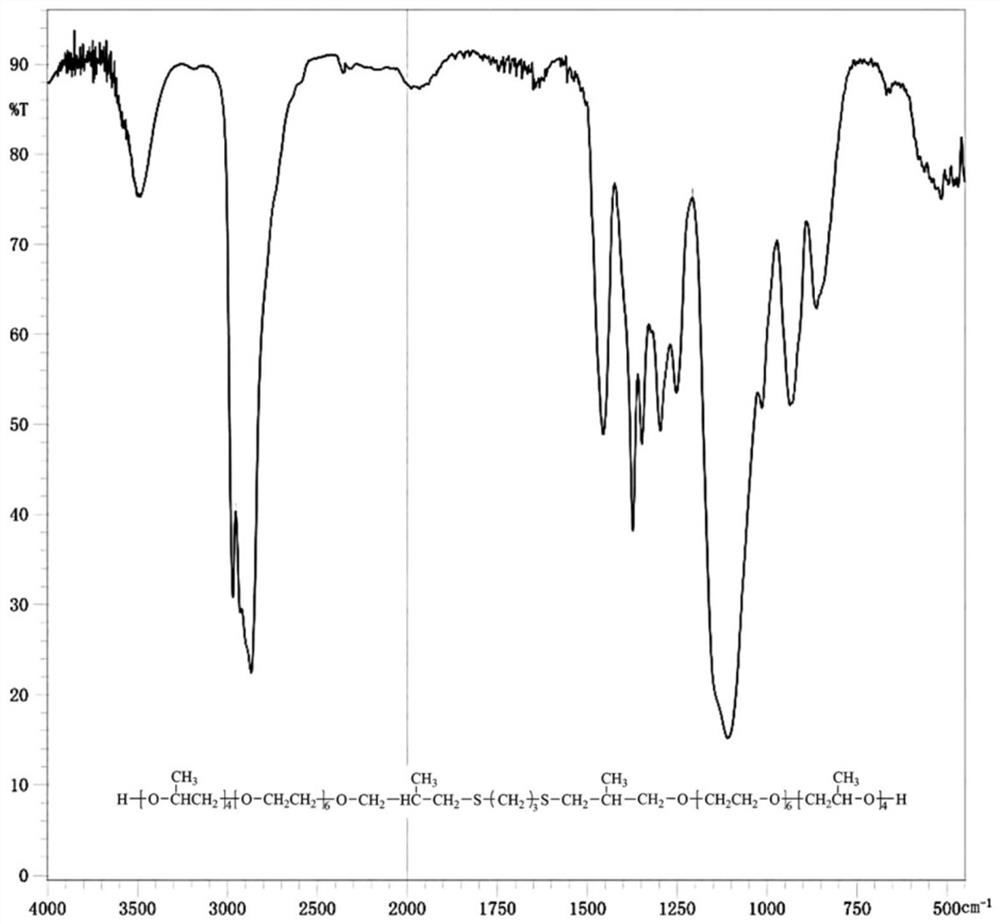

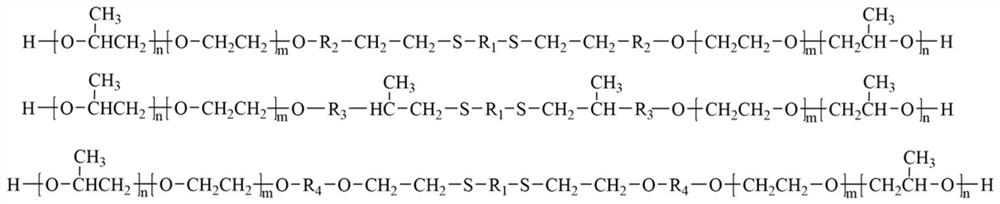

Method used

Image

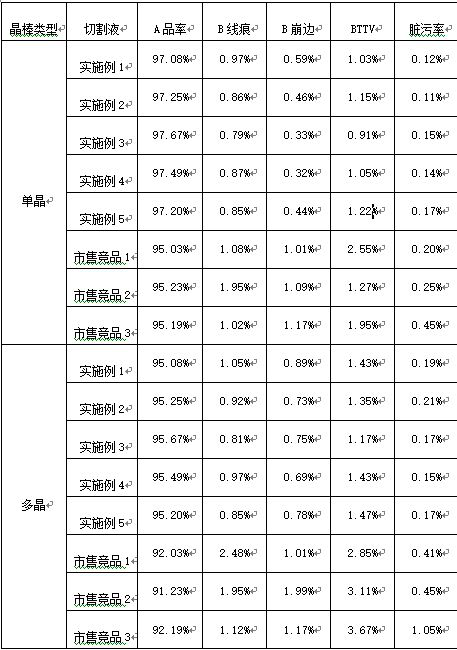

Examples

Embodiment 1

[0037] The parts by weight of the formula are as follows (the total parts by weight is 100):

[0038] Modified polyether: 18

[0039] water: balance

[0040] The thioether modifier of the above-mentioned modified polyether is 1,3-dimercaptopropane, and the polyether is propylene polyoxyethylene polyoxypropylene ether (m=5, n=5).

Embodiment 2

[0042] The parts by weight of the formula are as follows (the total parts by weight is 100):

[0043] Modified polyether: 15

[0044] water: balance

[0045] The silicon modifier of the above-mentioned modified polyether is 1,3-dimercaptopropane, and the polyether is methyl pentyl polyoxyethylene polyoxypropylene ether (m=6, n=4).

Embodiment 3

[0047] The parts by weight of the formula are as follows (the total parts by weight is 100):

[0048] Modified polyether: 15.5

[0049] water: balance

[0050] The silicon modifier of the above-mentioned modified polyether is 1,4-dimercaptopropane, and the polyether is vinyl butanediol ether polyoxyethylene ether polyoxypropylene ether (m=8, n=6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com