Rubber-iron integrated backlight structure capable of avoiding defective product generated after tests

A backlight structure and post-test technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as poor product reliability, inability to dissipate water vapor, and membrane arching, so as to improve reliability and avoid product defects. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

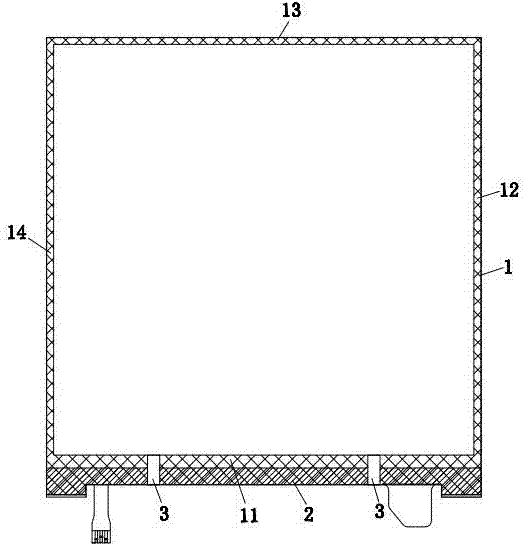

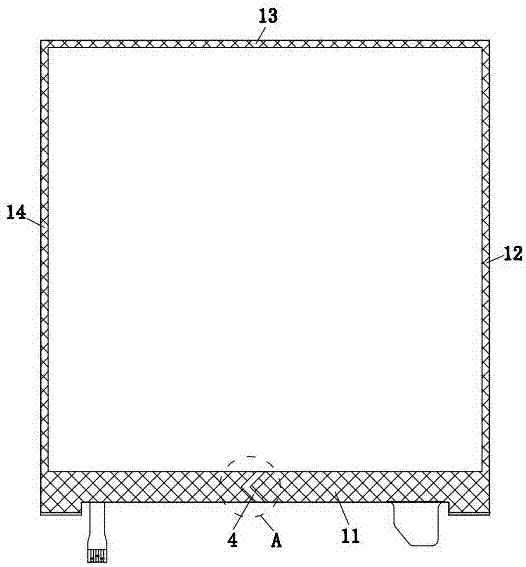

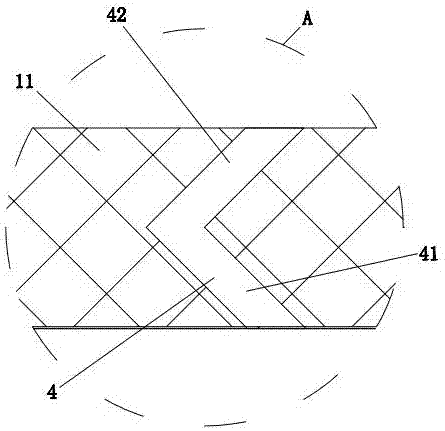

[0027] A rubber-iron integrated backlight structure that can avoid product failure after testing in this embodiment, such as Figure 1 to Figure 3 As shown, it includes an iron frame, a plastic frame covered with the iron frame and integrally formed with the iron frame; the plastic frame includes a first plastic frame body 1, and a second plastic frame body 2 arranged on the side of the first plastic frame body 1 ; The first plastic frame body 1 includes a first frame 11, a second frame 12, a third frame 13 and a fourth frame 14 which enclose a rectangular structure in turn; the second plastic frame body 2 is arranged on one side of the first frame 11; The second plastic frame body 2 is provided with a plurality of first ventilation holes 3 , and the first frame 11 is provided with a second ventilation hole 4 . Since the second plastic frame body 2 is provided with a number of first ventilation holes 3, and the first frame 11 is provided with a second ventilation hole 4, it ca...

Embodiment 2

[0033] An embodiment 2 of the rubber-iron integrated backlight structure of the present invention that can avoid product failure after testing. The difference between this embodiment and embodiment 1 is that in this embodiment, the second plastic frame body 2 is opened There are three first air holes 3, and the three first air holes 3 are evenly arranged on the second plastic frame body 2. The three first air holes 3 can effectively solve the problem of the plastic-iron integrated backlight structure and FOG assembled into a finished LCM. , After environmental tests (such as high temperature and high humidity, high temperature and high pressure or low temperature), problems such as membrane material arching, difficult moisture distribution and product deformation occur, thereby improving the reliability of LCM finished products. In this embodiment, the included angle between the first hole portion 41 and the second hole portion 42 is set to be 80 degrees. The angle between the...

Embodiment 3

[0035] Embodiment 3 of the rubber-iron integrated backlight structure of the present invention that can avoid product failure after testing. The difference between this embodiment and Embodiment 1 is that in this embodiment, the first hole 41 and the second hole The included angle between the two holes 42 is set to be 100 degrees. The angle between the first hole portion 41 and the second hole portion 42 can not only dissipate the water vapor, but also prevent the membrane material from arching and product deformation. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com