Fresh konjak mashing machine

A technology of fresh konjac and mashing, applied in food science, application, juice extraction, etc., can solve the problems of high labor cost, poor taste of konjac tofu, high labor cost, etc., and achieve the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

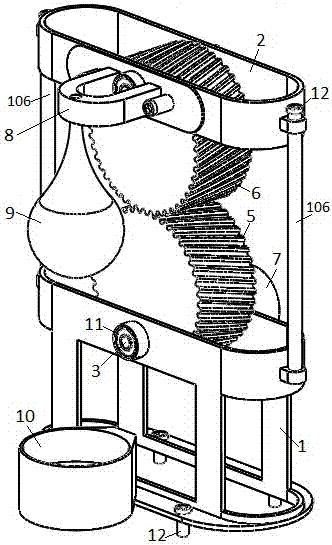

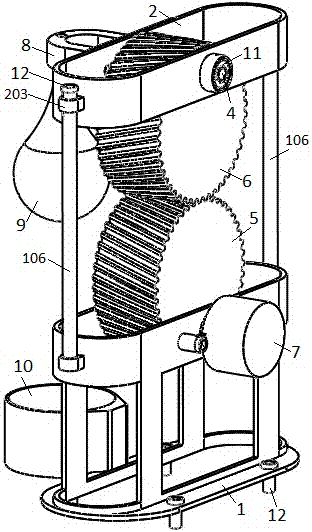

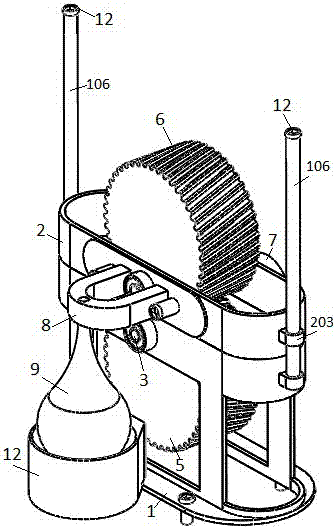

[0045] A kind of fresh konjac beating and pureeing machine of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment.

[0046] A fresh konjac pulping machine is characterized in that it includes a fixed frame 1, a moving frame 2, a lower shaft 3, an upper shaft 4, a lower gear 5, an upper gear 6, a motor 7, a hammering bracket 8, a hammer 9, Holder 10, bearing 11, screw 12.

[0047] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the fixed piece 101 at the bottom of the fixed frame 1 is fixed on the operating platform by screws 12, and the left and right ends of the fixed frame 1 are respectively provided with vertical upright columns 106; the left and right ends of the mobile frame 2 are provided with The column sleeve 203, the column sleeve 203 is set on the column 106 of the fixed frame 1; the front and rear directions of the lower rotating shaft 3 are installed on the fixed frame 1, and the low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap