Horizontal pelletizing device and extruder

A pelletizing and horizontal technology, which is applied in the field of plastic processing equipment, can solve the troublesome, time-consuming and labor-intensive problems of knife changing in the pelletizing device, and achieve the effect of solving the troublesome and convenient operation of knife changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

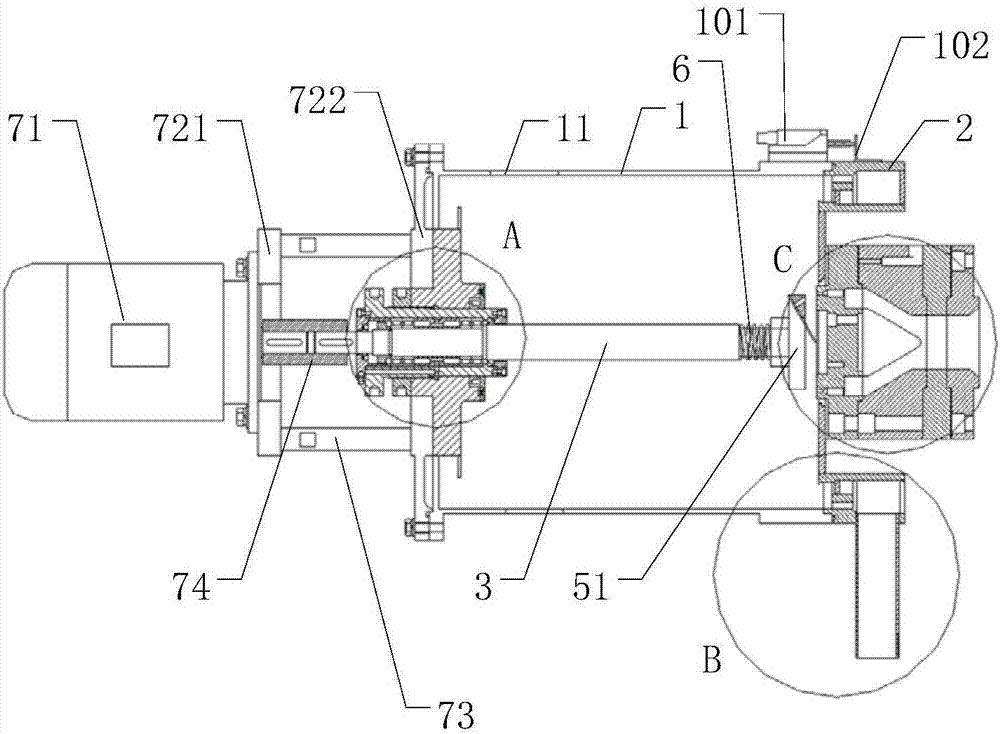

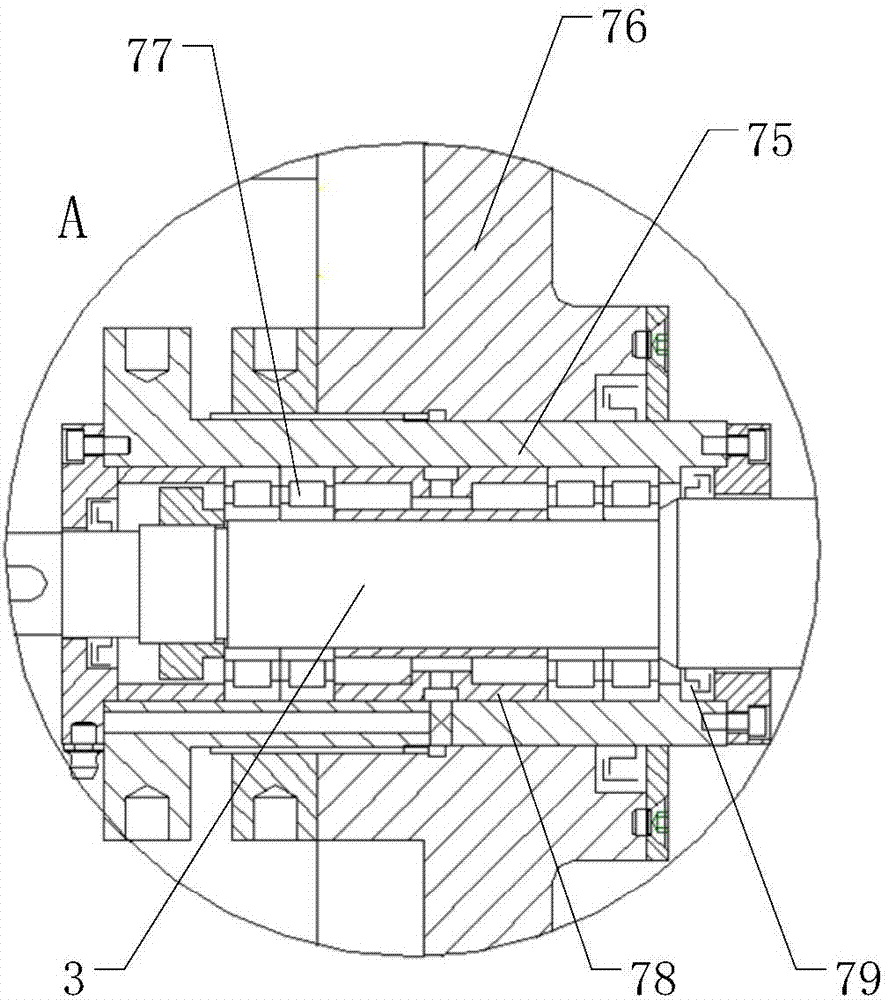

[0068] see Figure 1-Figure 6 As shown, this embodiment provides a horizontal pelletizing device, including a water ring cover 1, a water jacket 2, a rotating shaft 3, a guide rail 91 and a slider 92;

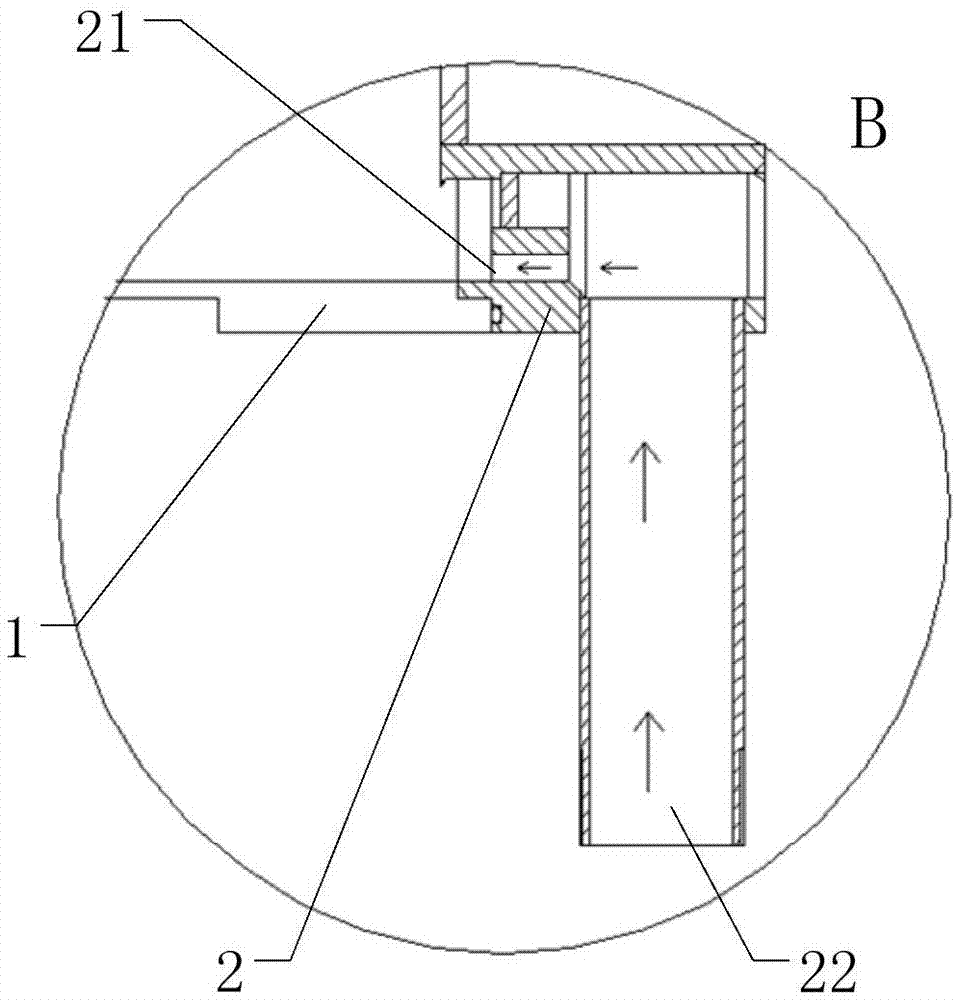

[0069] A cavity is opened in the water ring cover 1, and one end of the cavity along the extension direction penetrates the water ring cover 1, forming a first opening on the water ring cover;

[0070] The water jacket 2 is arranged on the first opening of the water ring cover, so that the water ring cover 1 and the water jacket 2 form a shell;

[0071] The rotating shaft 3 is arranged in the cavity and connected with the water ring cover 1, the rotating shaft 3 can rotate relative to the water ring cover 1, the axis direction of the rotating shaft 3 is in line with the extending direction of the cavity parallel;

[0072] A cutterhead 51 is connected to the side of the rotating shaft 3 close to the water jacket 2, and a blade 52 is arranged on the cutterhead 51;

[0073] The...

Embodiment 2

[0143] Embodiment 2 provides an extruder, said extruder includes the horizontal pelletizing device described in Embodiment 1, and the technical features of the horizontal pelletizing device disclosed in Embodiment 1 are also applicable to this embodiment, The technical features of the disclosed horizontal pelletizing device in Embodiment 1 will not be described repeatedly. The implementation of the extruder will be further described in detail below with reference to the accompanying drawings.

[0144] In order to save space, the improved features of this embodiment are also reflected in Figure 1-Figure 6 in, therefore, combined with Figure 1-Figure 6 The configuration of this example will be described.

[0145] see Figure 1-Figure 6 As shown, the extruder provided in this embodiment, including the horizontal pelletizing device, further solves the technical problems of troublesome, time-consuming and labor-intensive tool change of the pelletizing device in the prior art. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com