Sweetener composition and food containing same

A technology of composition and sweetener, applied in the direction of food ingredients, food ingredients as taste improvers, food science, etc., can solve the problems of difficult practical application of cost, low content, etc., achieve excellent sweetness quality and improve sweetness quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111]The extract was obtained by extracting three times from 1000 g of dry Stevia leaves with 15 volumes of warm water. The resulting extract was passed through a column packed with 1000 ml of nonpolar adsorption resin (Diaion HP20, Mitsubishi Chemical Corporation) and washed with water. The sweet component is then eluted with ethanol, and the eluate is vacuum concentrated to remove the alcohol. The concentrate was diluted with water so that the solids were about 4%. The mixture was passed through a column packed with 200 ml of cation exchange resin (Diaion PA408, Mitsubishi Chemical Corporation) and a column packed with 200 ml of anion exchange resin (Diaion WA30, Mitsubishi Chemical Corporation) and decolorized. The decolorized solution was subjected to reduced pressure to concentrate the solution until the solid was about 30%, and the solution was dried with a vacuum drier to obtain 105 g of powder (powder a).

Embodiment 2

[0113] Powder a obtained in Example 1 contained 65% by weight of rebaudioside, 11% by weight of stevioside and 8% by weight of rebaudioside C. After the powder was heated and dissolved in 10 volumes of 90% ethanol, the solution was cooled to 4°C and left to stand for 24 hours. Crystals (90% by weight of rebaudioside A, 4% by weight of stevioside C and 1% by weight of rebaudioside C) obtained after the solution was allowed to stand were separated and removed.

Embodiment 3

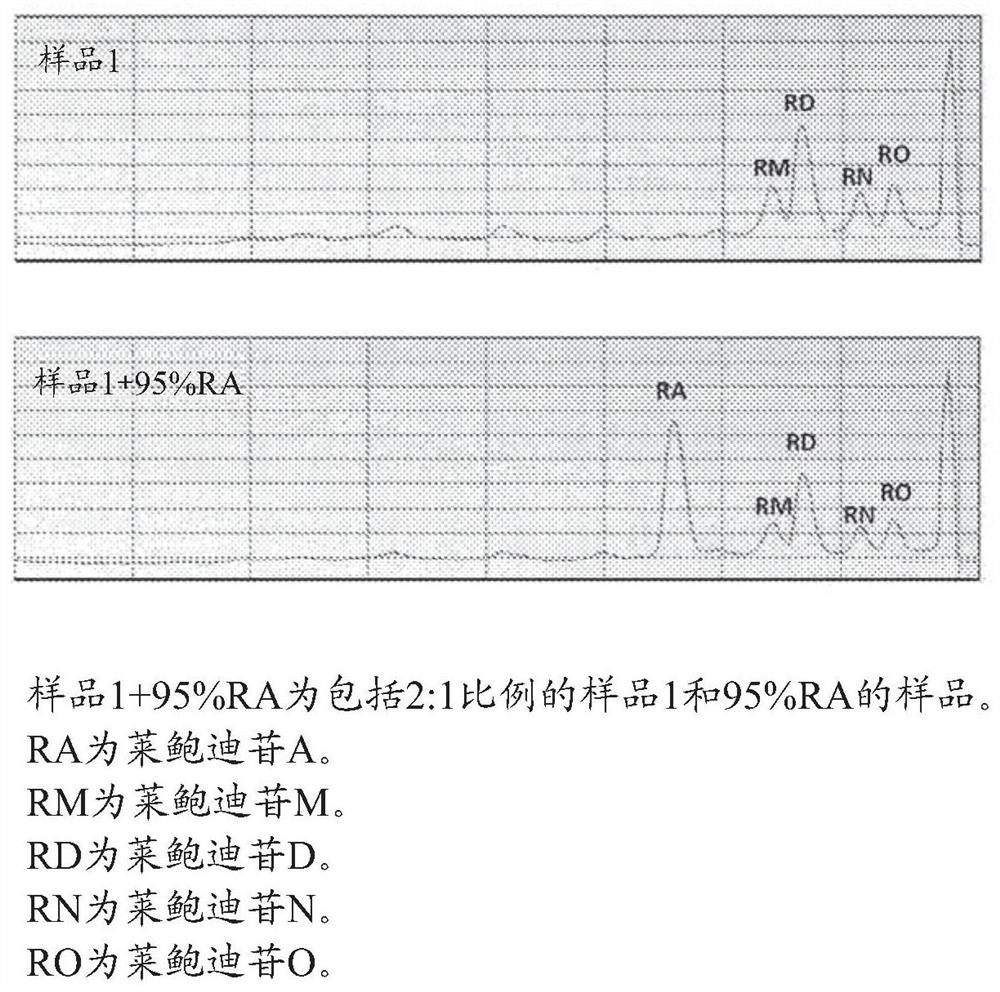

[0115] The mother liquor separated in Example 2 was concentrated in vacuo. Water was added to bring the concentrated solids to about 4%. The mixture was again passed through a column filled with nonpolar adsorption resin, a column filled with cation exchange resin, and a column filled with anion exchange resin, and concentrated and dried. After drying, the crystallization operation and removal of crystals were repeated three times. In addition, filtration was performed after adding activated carbon. The filtrate was again passed through a column filled with nonpolar adsorption resin, a column filled with cation exchange resin, and a column filled with anion exchange resin, and concentrated and dried. The final isolated mother liquor obtained by repeating the same procedure until rebaudioside A, stevioside, etc. could no longer be removed was concentrated and dried to obtain 8.5 g of a steviol glycoside-containing powder (sample 1).

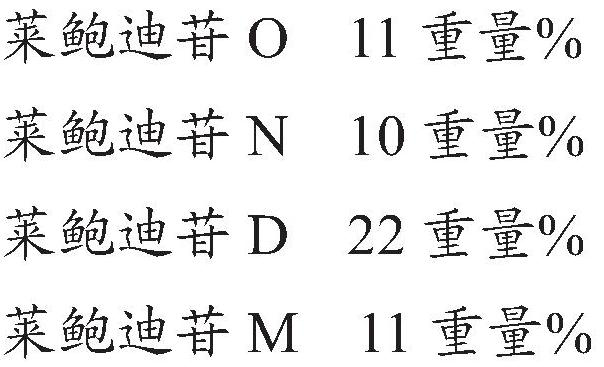

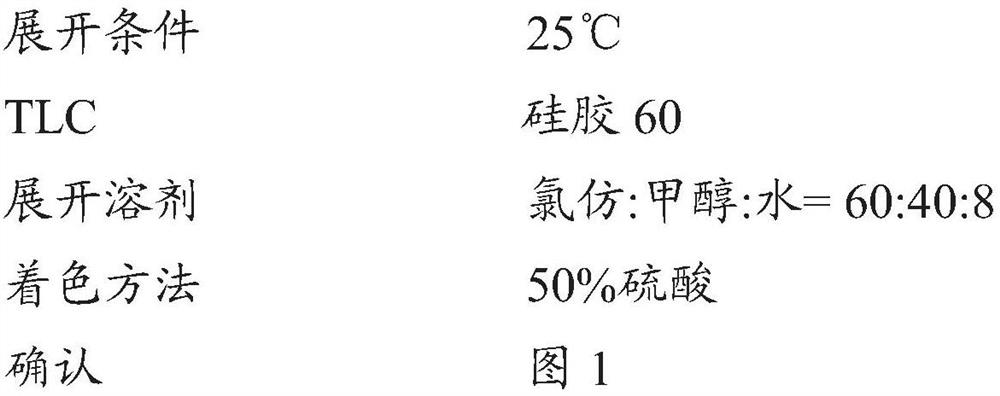

[0116] The components of the obtained sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com