A method for enzymatic variable temperature high throughput preparation of glucosyl steviol glycosides

A technology based on stevioside and steviol glycoside, which is applied in the field of sweetener biosynthesis, can solve the problems of no rules to follow, no universal significance, and different effective stabilizers, so as to improve the quality of sweetness and ensure high efficiency and utilization, sweetness and mouthfeel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of cyclodextrin glucosyltransferase (cyclodextrin glucosyltransferase)

[0036] Geobacillus sp. strain (Geobacillus thermoglucosidasius, ATCC 43742) was used as the production strain, and the inoculation amount was 8% and then batch fermentation was carried out. The medium composition is: glucose 0.8%, lactose 0.05%, peptone 1.2%, yeast extract 2.4%, K 2 HPO 4 0.3%, KH 2 PO 4 0.98%, CaCl 2 0.28%. When the dissolved oxygen rises to 85%, start to feed the feed solution. The temperature is controlled at 33-37°C during the growth stage of the bacteria, and the dissolved oxygen is maintained at 25%-30%; 600 When it reaches 25, add 1% (mass volume fraction) glycine; when the bacteria OD 600 When it reaches 50, reduce the temperature to 23-27℃ and continuously add 0.2-0.4g·l -1 ·H -1 Lactose, while supplementing the feed liquid with a decreasing gradient; after 30 hours of fermentation, the fermentation was terminated, and the bacteria were removed by centrif...

Embodiment 2

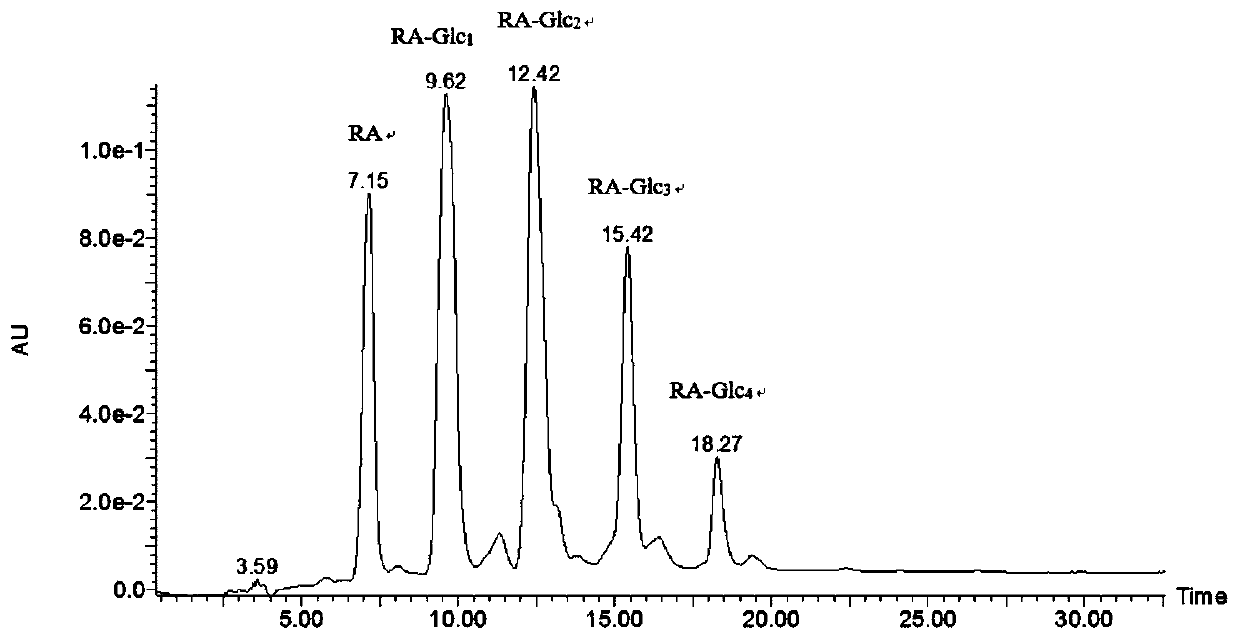

[0037] Example 2 Preparation of glucosyl steviol glycosides with tapioca dextrin and rebaudioside A as raw materials

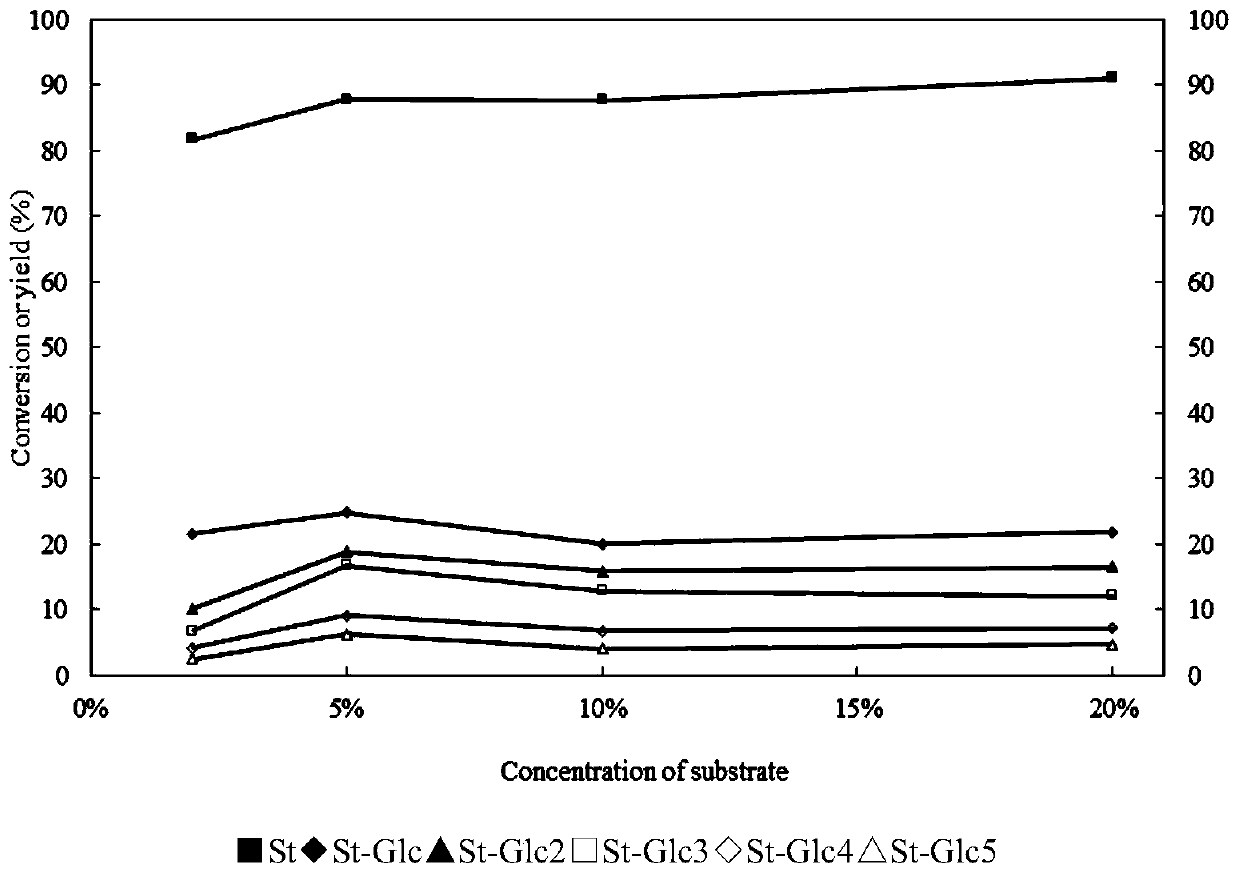

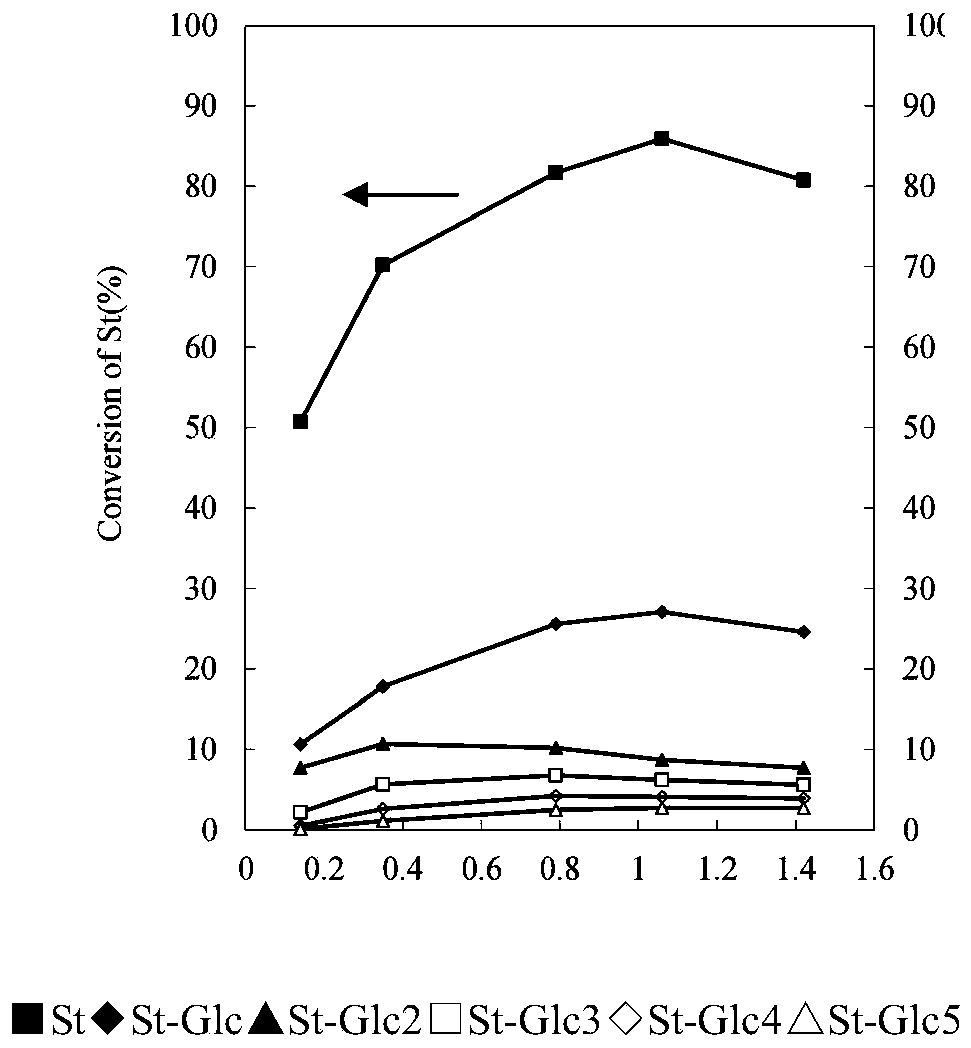

[0038] Add 100 kg of water into the jacketed reactor, and after heating to 85° C., 15 kg of tapioca dextrin and 15 kg of rebaudioside A (HPLC content 98%) are added successively, and stirred to dissolve. After being fully dissolved, quickly cool to 65°C, and add 5 mL of 1% calcium chloride and barium chloride (mass ratio 0.2:1) aqueous solution, 4 g of glycerol and 250 kU of the ring obtained in Example 1 into the jacketed reactor under stirring. A solution of dextrin glucosyltransferase. Reacted at 65°C for 3 hours, then heated to 75°C for 24 hours, and then heated to 80°C for 10 hours to complete the reaction. The product is directly spray-dried to obtain glucosyl steviol glycoside with a moisture content of 2.1%. The product can be directly used in products that do not require a total glycoside content of not less than 95% without decolorization. The content...

Embodiment 3

[0045] Example 3 Preparation of glucosyl steviol glycosides with β-cyclodextrin and rebaudioside A as raw materials

[0046] Add 100 kg of water into the jacketed reactor, and after heating to 82° C., add 10 kg of β-cyclodextrin and 25 kg of rebaudioside A (HPLC content 97%), and stir to dissolve. After being fully dissolved, quickly cool to 60°C, add 10mL of 1% calcium chloride and barium chloride (mass ratio 0.5:1) aqueous solution, 2g glycerol, 2g sorbitol and 1000kU into the jacketed reactor under stirring. 1 The resulting cyclodextrin glucosyltransferase solution. The reaction was carried out at 60°C for 3 hours, then the temperature was raised to 74°C for 15 hours, and then the temperature was raised to 80°C for 8 hours to complete the reaction. The product is spray-dried to obtain a glucose-based steviol glycoside with a moisture content of 2.0%. The product can be directly used in products that do not require a total glycoside content of not less than 95% without decolor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com