Position control of a boom tip

A boom and control system technology, which is applied in the processing of building materials, load hanging components, construction, etc., can solve the problem of not being able to use position control, and achieve the effect of preventing false values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

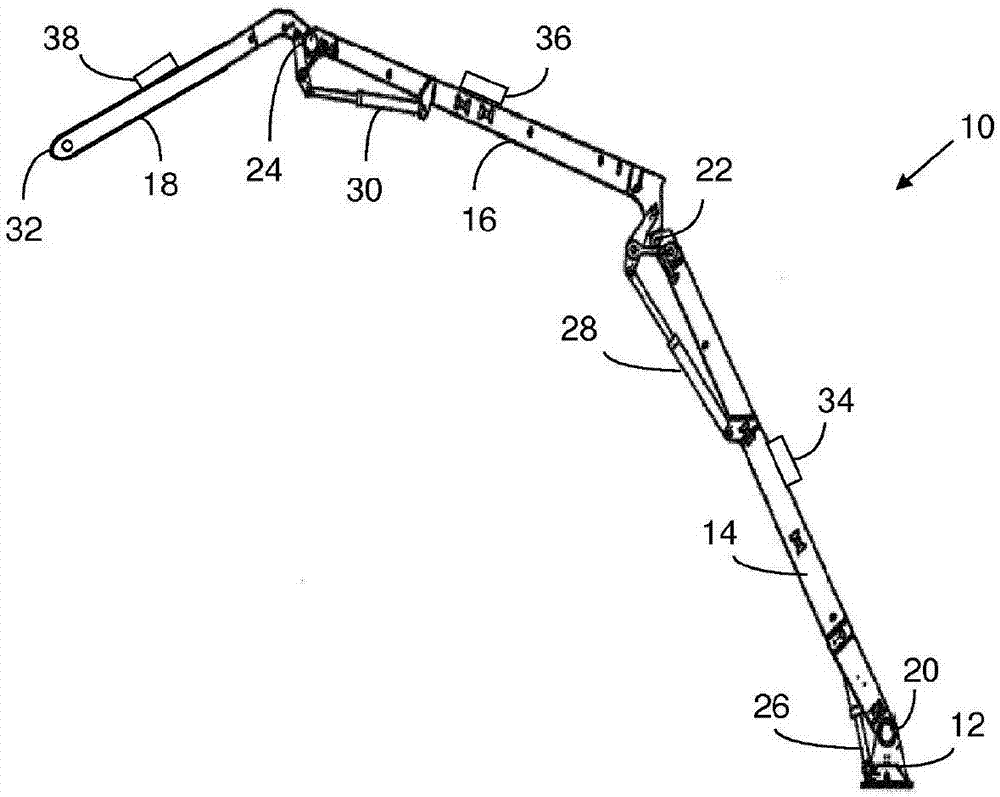

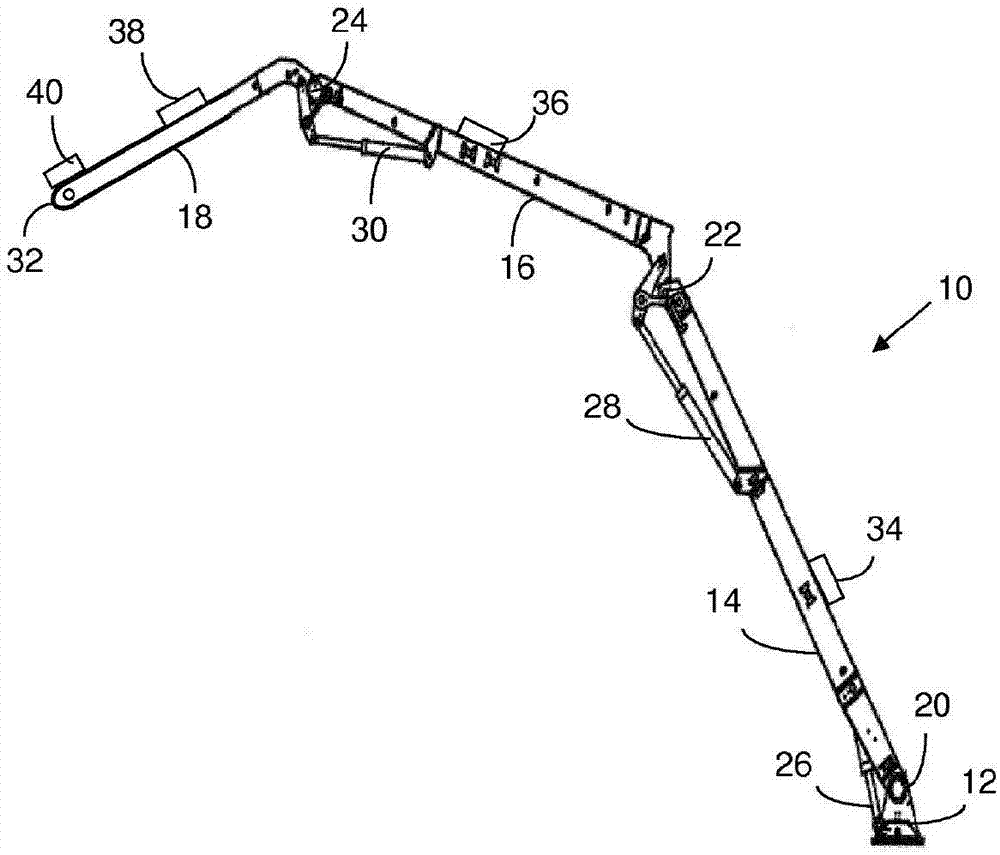

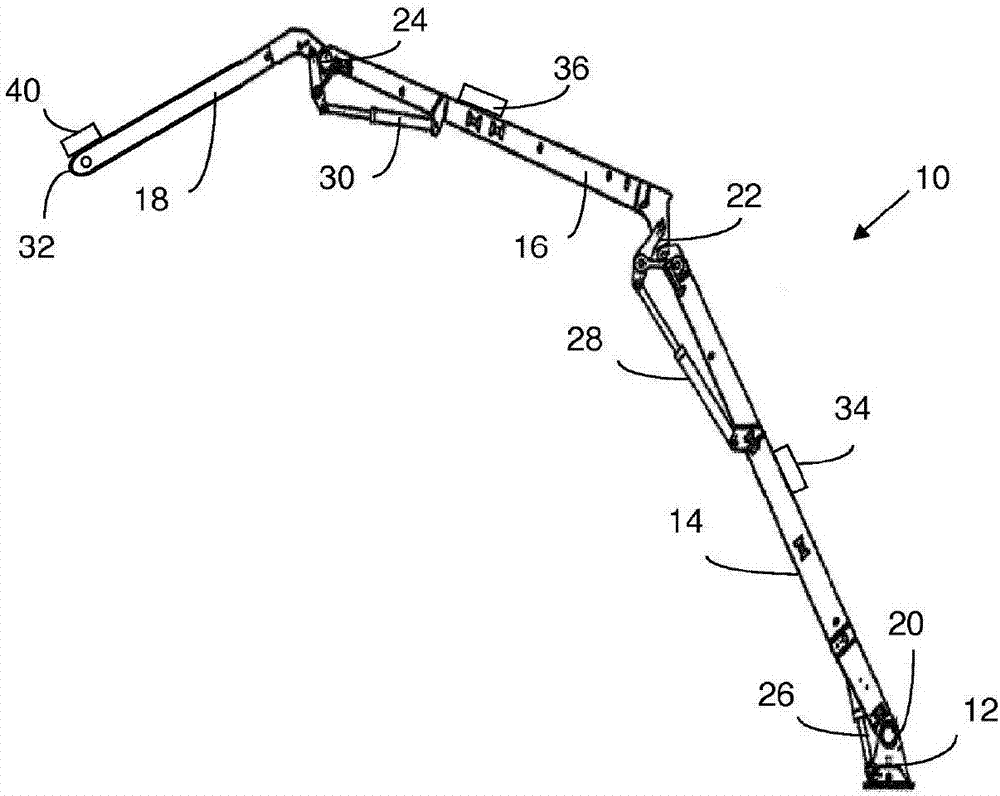

[0027] figure 1 A schematic view of a jib arm 10 according to the invention is shown with the means for measuring inclination 34 , 36 , 38 in a first configuration. The large robotic arm has a jib arm 10 which is foldable and has a turntable 12 rotatable about a vertical axis and a plurality of jib sections 14 , 16 , 18 . The boom sections 14 , 16 , 18 are pivotable to a limited extent relative to the adjacent boom sections 14 , 16 , 18 or the turntable 12 by means of a drive assembly 26 , 28 , 30 , respectively. The boom arm 10 preferably has three to five boom sections 14 , 16 , 18 . The large robotic arm according to the invention has at least one inertial sensor 34, 36, 38 for sensing the inclination of the boom section 14, 16, 18 relative to the earth. The inertial sensors 34, 36, 38 all preferably include biaxial acceleration sensors and rotational speed sensors. The axis of the rotational speed sensor is ideally positioned orthogonally to the acceleration axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com