A moisture-retaining self-curing concrete pouring material

A self-curing and concrete technology, which is applied in the field of building materials, can solve the problems of insufficient use of mixing water and large water demand, and achieve the effects of good work performance, reduced mixing water consumption, and reduced drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

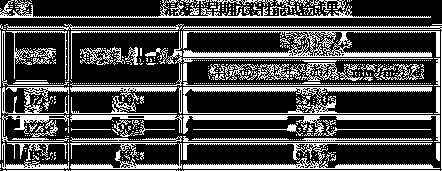

Embodiment 1

[0021] Concrete lining construction of water delivery channel of a water conservancy project in Huanxian County, Gansu Province. The project is located in an arid zone, with dry climate, evaporation far exceeds precipitation, and requires high maintenance and crack resistance of concrete. The preparation method of the channel lining concrete pouring material used is as follows:

[0022] The first step is to accurately weigh 145kg of water, 322kg of cement, 821kg of natural medium sand, 1095kg of gravel, and 16.11kg of hydrophobic agent;

[0023] In the second step, add the weighed cement, sand, gravel, and hydrophobic agent into the mixer, and dry mix for 1 minute;

[0024] In the third step, slowly add the mixing water taken in the first step into the material of the mixer, and stir for 3 minutes;

[0025] In the fourth step, the mixed material obtained in the third step is taken out, and the slump and workability tests are carried out, and pouring can be carried out after m...

Embodiment 2

[0027] For the construction of a water conservancy project reservoir in Lanzhou, Gansu, the bottom plate of the reservoir is a large-area thin-walled structure, and the requirements for impermeability and crack resistance are high. The preparation method of the concrete pouring material used is:

[0028] The first step is to accurately weigh 150kg of water, 267kg of cement, 67kg of fly ash, 758kg of artificial medium sand, 1148kg of gravel, and 8.33kg of hydrophobic agent;

[0029] In the second step, add the weighed cement, fly ash, sand, gravel, and hydrophobic agent into the mixer, and dry mix for 1 minute;

[0030] In the third step, slowly add the mixing water taken in the first step into the material of the mixer, and stir for 3 minutes;

[0031] In the fourth step, the mixed material obtained in the third step is taken out, and the slump and workability tests are carried out, and pouring can be carried out after meeting the requirements.

[0032] In this case, the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com