System for producing three-dimensional objects

A technology of three-dimensional objects and objects, which is applied in the directions of processing and manufacturing, manufacturing tools, additive manufacturing, etc., and can solve problems such as equipment not being able to expand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

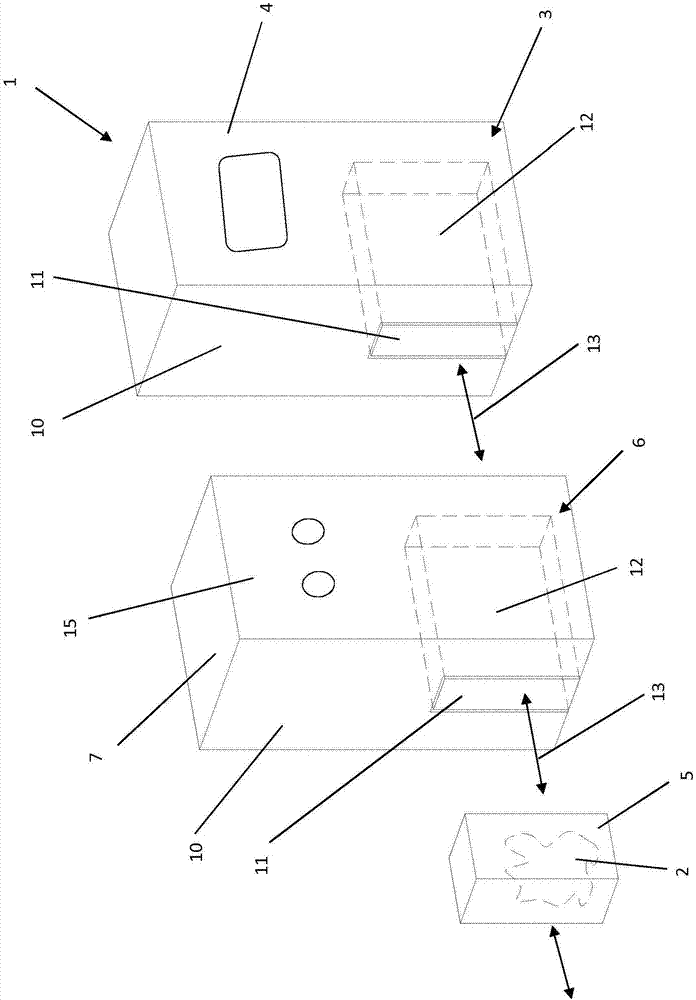

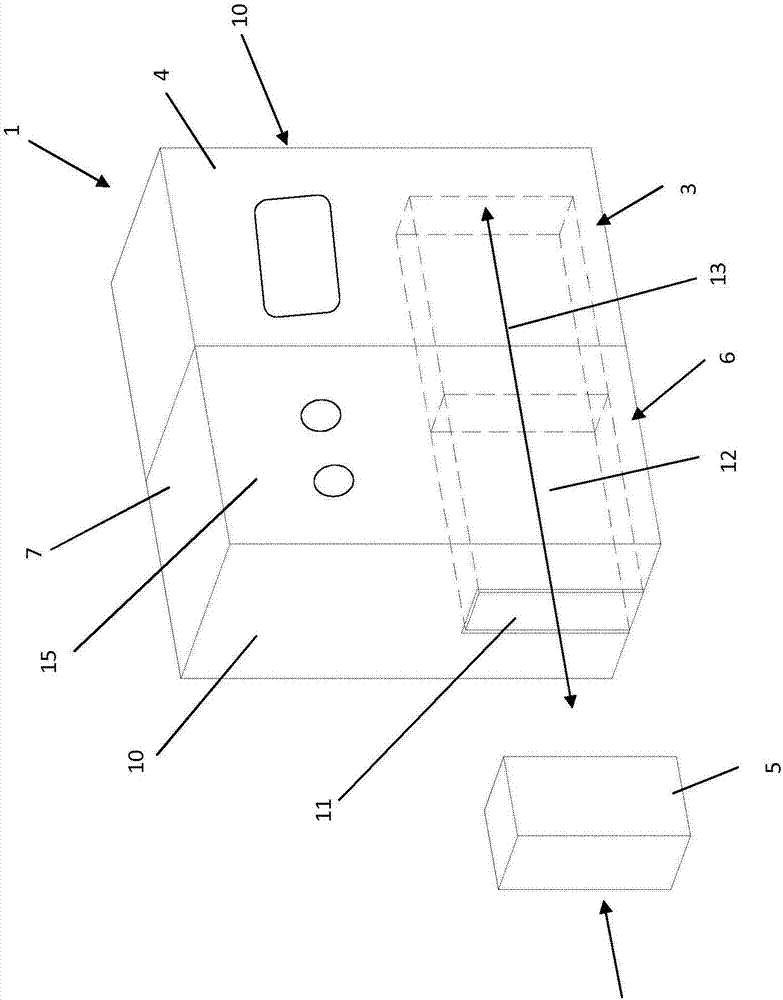

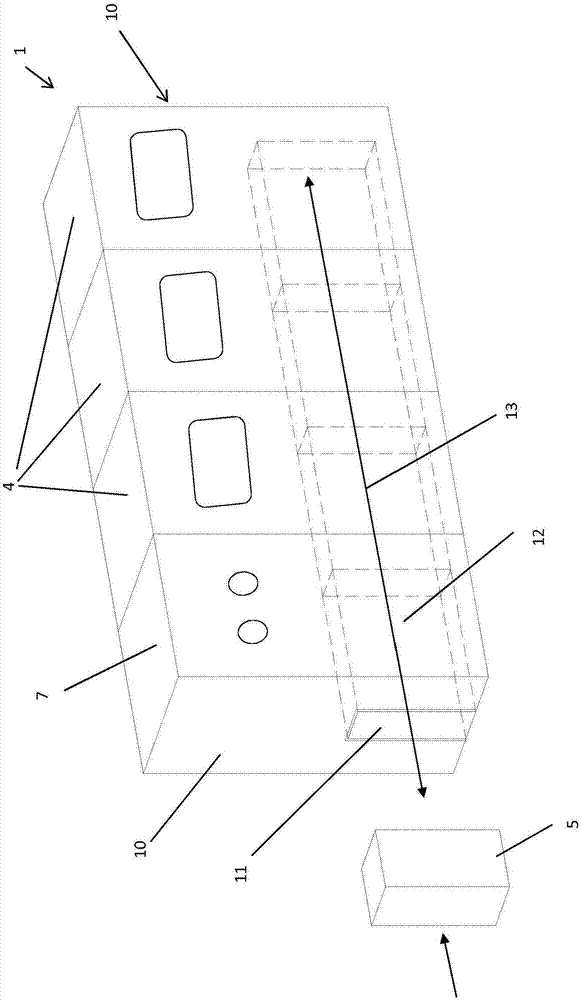

[0031]The system 1 shown in the illustration of the drawing is used to produce a three-dimensional object 2 by successively curing layers of a construction material that can be cured by means of radiation, in particular laser radiation, at locations corresponding to the respective cross-section of the object 2 . Such a system 1 comprises at least one process station 4 arranged in a first housing 3 for carrying out a layer-by-layer generative construction process in a construction vessel 5 and in at least one second housing 6 for The handling station 7 of the manufactured object 2 is removed from the container 5 , and the building container can be moved between the process station 4 and the handling station 7 .

[0032] At least one process station 4 and at least one control station 7 are arranged in a separate, detachable or individually set up housing unit (3, 6), which in the exemplary embodiment in its side wall region 10 are provided with supply openings 11 and are config...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap