Spinous Process Spacer Hammock

a technology of spacers and hammocks, which is applied in the field of spinous process spacer hammocks, can solve the problems of wear away of the spinous process bone, difficult implantation of devices, and inability to stay in place, so as to reduce the distraction, increase the distraction, and reduce the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

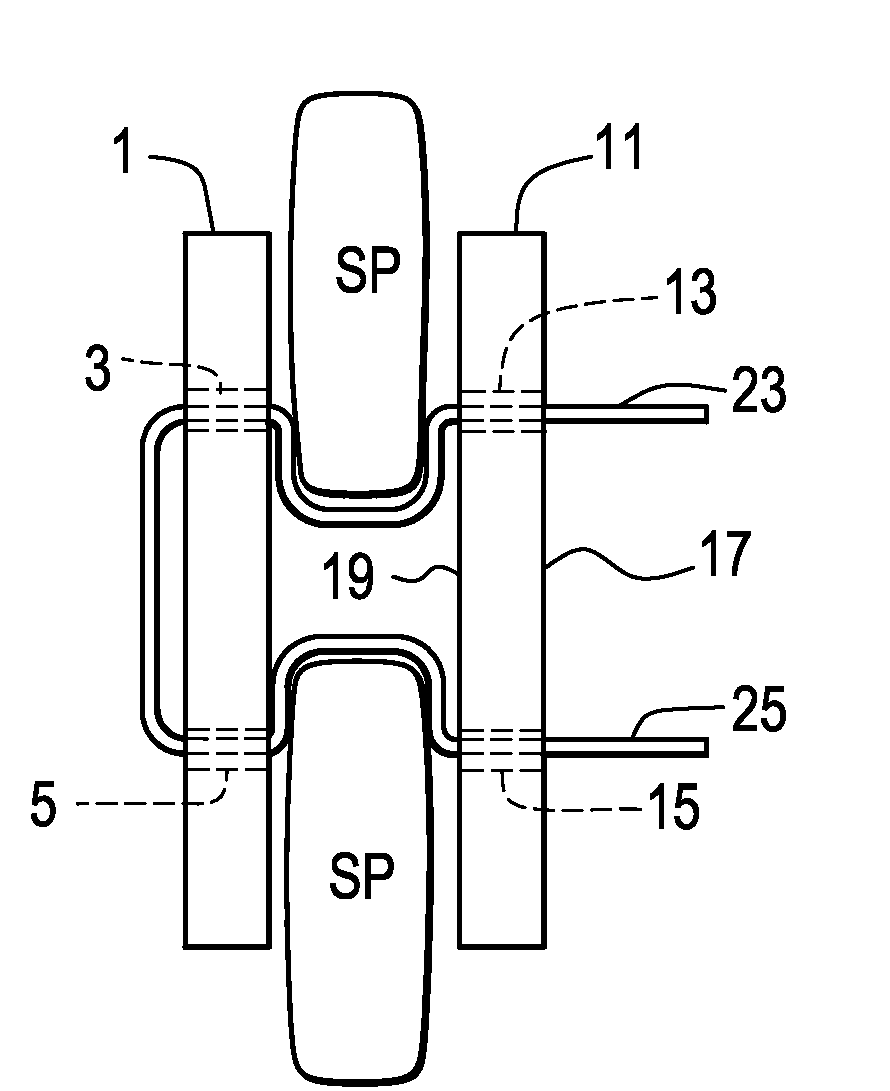

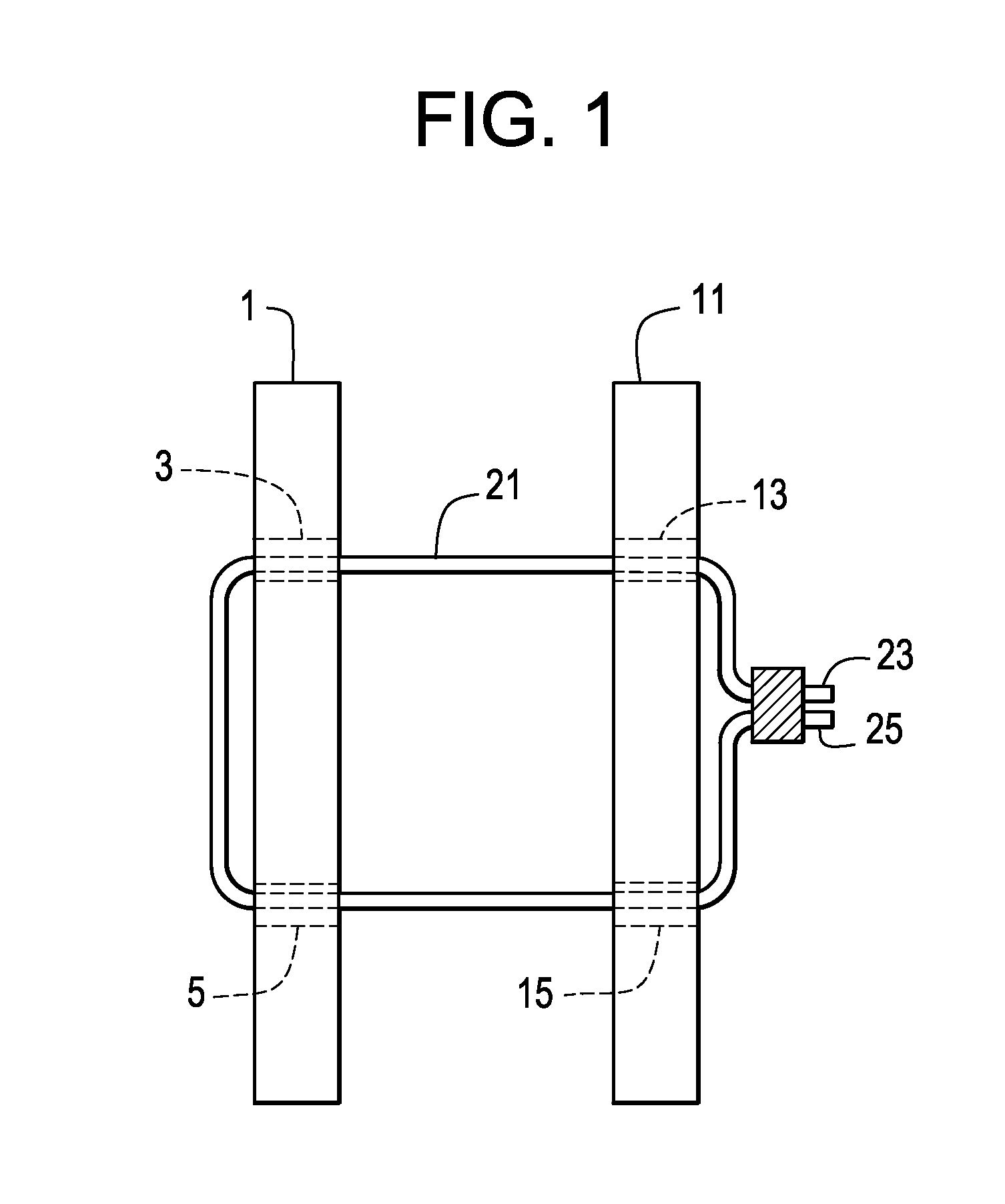

[0017]Now referring to FIG. 1, there is provided an interspinous spacer comprising:[0018]a) a first brace 1 having an upper throughhole 3 and a lower throughhole 5,[0019]b) a second brace 11 having an upper throughhole 13 and a lower throughhole 15,[0020]c) a ligament 21 having a first end 23 and a second end 25,

wherein the ligament extends from the upper throughhole of the first brace through the upper throughhole of the second brace, then through the lower throughhole of the second brace, then through the lower throughhole of the first brace, and

wherein the first end of the ligament is in mechanical connection with the second end of the ligament between the upper throughhole and a lower throughhole of the first brace.

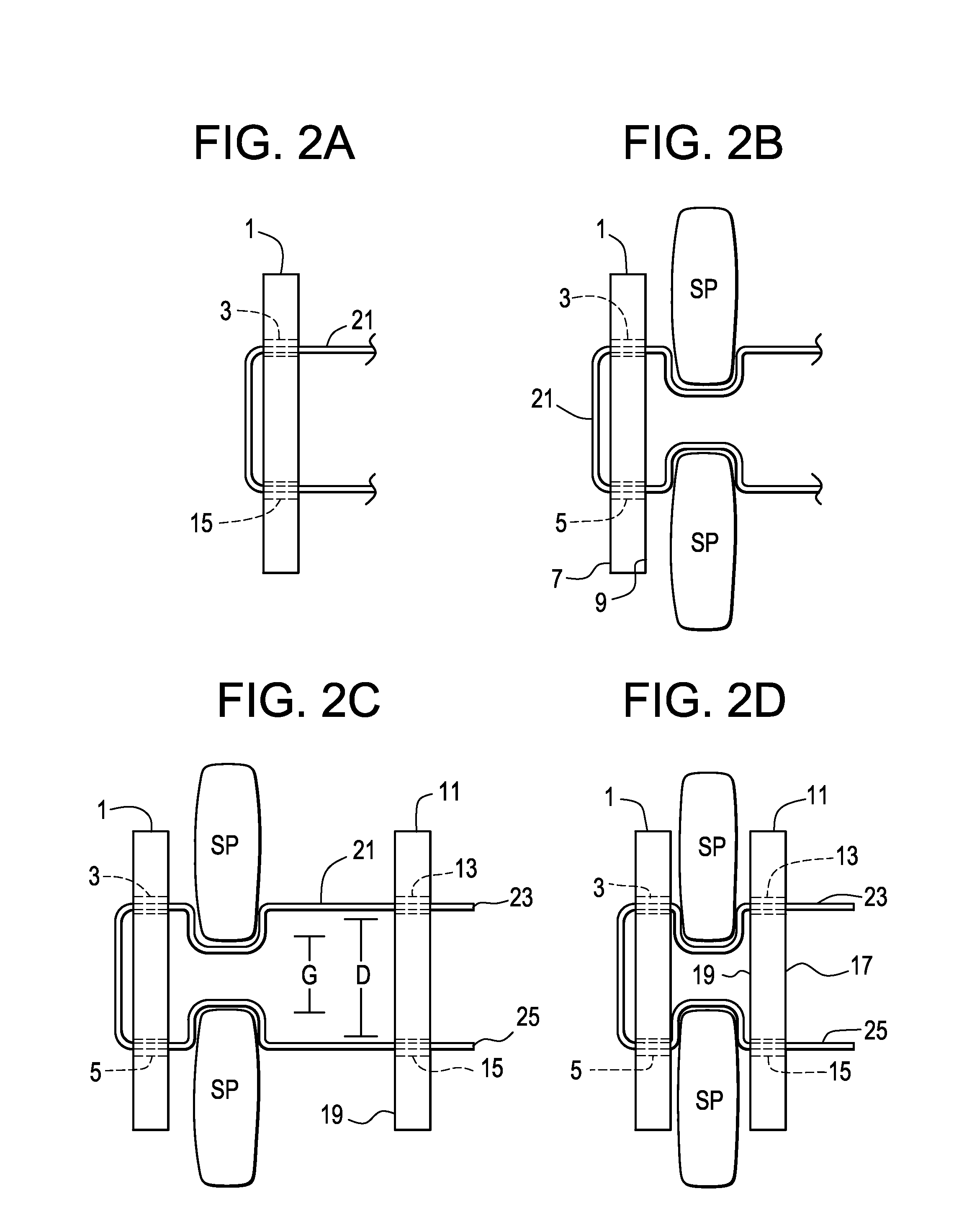

[0021]Now referring to FIGS. 2a-2f, the spacer is assembled in situ as follows: First, and now referring to FIG. 2a, the ligament is drawn through each of the upper and lower holes of a first brace, with each end of the ligament exiting the respective holes in the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com