Space operation robot

An operating robot and space technology, applied in the field of space and space exploration, can solve the problems of small working range, astronaut error, and inconvenient movement of robots, and achieve the effect of flexible movement and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

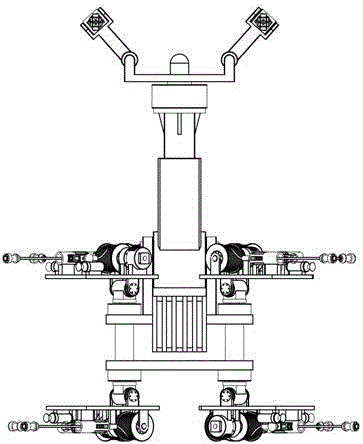

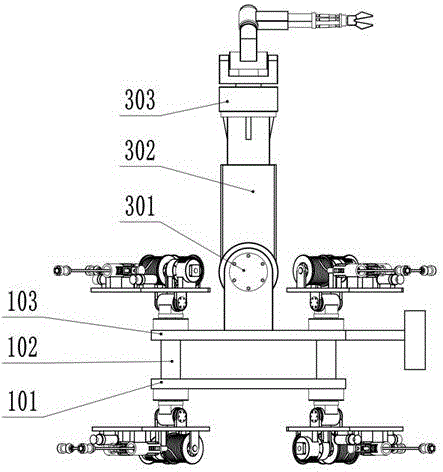

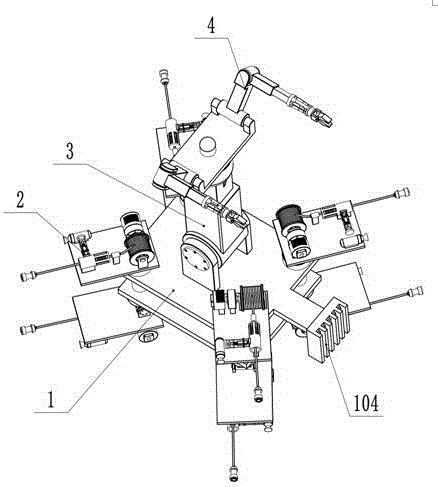

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, a space working robot includes a frame 1, eight fixed modules 2, a main arm module 3, and two working arm modules 4, and is characterized in that: the eight fixed modules 2 pass through respective first The lower end surface of the motor 204 is fixedly installed on the four corners of the lower end surface of the lower bottom plate 101 of the frame 1 and the four corners of the upper end surface of the upper bottom plate 103; The upper end surface of the bottom plate 103 is in the center; the two working arm modules 4 are respectively installed on the left and right sides of the upper end surface of the second turntable 304 of the main arm module 3 through the third joint 401 at the end;

[0022] The frame 1 includes a lower base plate 101, four pillars 102, an upper base plate 103, and a tool seat 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com