Automatic opening device for oil box cover of car

A technology for automatic opening and fuel tank cap, applied in power plant, vehicle parts, transportation and packaging, etc., can solve the problems of complex operation, difficult realization, complex structure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the first technical scheme.

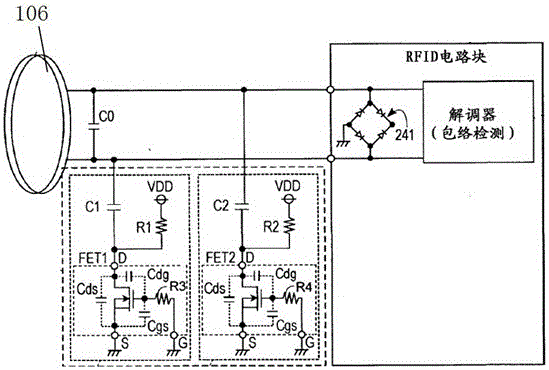

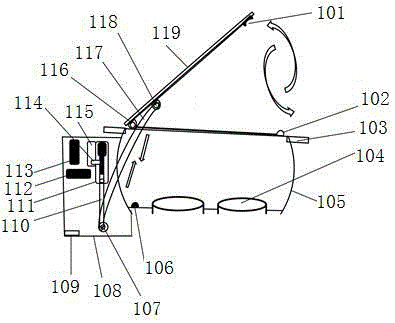

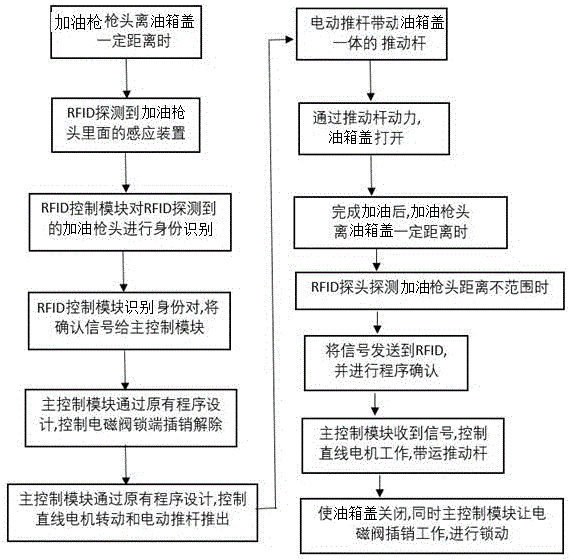

[0034] Such as Figure 1-5 As shown, the automatic opening device of the fuel tank cap of the automobile is arranged in the fuel tank cap 119 and placed in the side protective shell 108 of the fuel tank cap main body 105, and the fuel tank cap 119 passes through the mouth edge of the fuel tank cap main body 105 The fixed shaft 116 is connected, and the automatic opening device includes a push rod 117, a linear drive device, a main control module 113, an RFID control and detection module 112, and one end of the push rod 117 is connected to the fuel tank cover 119 through a first fixed shaft 118. The inner side, the other end is connected with the linear driving device through the second fixed rotating shaft 107, the linear driving device includes a linear motor main body 111, a linear electric push rod 110, and the outer surface of the linear electric push rod 110 The end is connected to the second fixed rotating shaft 107. Th...

Embodiment 2

[0053] Embodiment 2: the second technical solution.

[0054] Such as Figure 6 As shown, an automatic opening device for the fuel tank cap of an automobile, the linear drive device can be replaced by a motor turntable drive device;

[0055] The motor turntable drive device includes a rotating motor 201 and a turntable 202. The rotating rod of the turning motor 201 is connected to the turntable 202. The eccentric disc body of the turntable 202 is provided with a positioning hole 203, and the positioning hole 203 is provided with a push a rod hinge part, the push rod hinge part hinges the push rod 117;

[0056] The rotating motor 201 rotates to drive the turntable 202 to rotate, and the turntable 202 drives the push rod 117 to move to open or close the fuel tank cap 119 .

Embodiment 3

[0057] Embodiment 3: the third technical scheme.

[0058] Such as Figure 7-8 As shown, an automatic opening device for the fuel tank cap of an automobile, the linear drive device can be replaced by a push-pull electromagnet drive device;

[0059] The push-pull electromagnet driving device includes a metal buckle 301, a tension spring 302, a magnetic coil 304, a second locking pin 305, a movable iron core 307, a round tube shell 308, a guide rod 309, a return spring 310, and a stroke control Buckle 311, the inner wall of the round tube shell 308 is provided with a magnetic coil 304, the magnetic coil 304 is connected to the input power supply, and the magnetic coil 304 is provided with a movable iron core 307. The rod body of the movable iron core 307 is placed in the magnetic coil 304, the other end passes through the round tube shell 308 through hole to expose a section of rod body, the end of the rod body of the exposed part is provided with a mounting hole 306, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com