Ballast hopper vehicle motor

A technology for bucket trucks and storage batteries, applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve the effects of reducing mechanical vibration, reducing material costs, and avoiding line burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

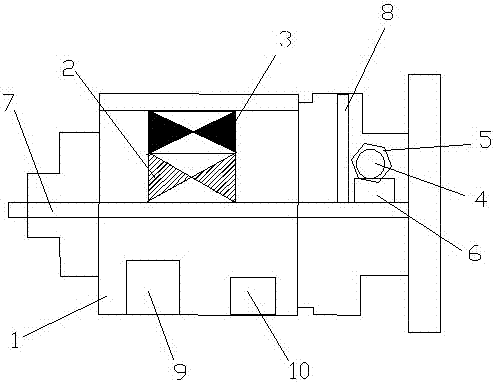

[0018] A ballast loaded bucket car motor, including a housing 1, a stator 2, a rotor 3, a fan 4, a windshield 5 and a storage battery 6, a rotating shaft 7 is arranged in the middle of the housing 1, and the stator 2 is arranged on the rotor 3 One end inside the housing 1 is provided with a partition 8, one side of the partition 8 is provided with the fan 4, and the other side of the partition 8 is provided with the stator 2 and the The rotor 3, the windshield 5 is arranged on the outside of the fan 4, the battery 6 is arranged below the fan 4, and the outer wall of the housing 1 is radially distributed with cooling ribs, and the cooling ribs have a diameter of Distributed at intervals, the heat dissipation ribs are covered with an outer cover plate, and the outer cover plate is provided with heat dissipation grooves and heat dissipation holes, and heat dissipation fins are arranged in the heat dissipation grooves, and the heat dissipation fins and the heat dissipation holes ar...

Embodiment 2

[0021] A ballast loaded bucket car motor, including a housing 1, a stator 2, a rotor 3, a fan 4, a windshield 5 and a storage battery 6, a rotating shaft 7 is arranged in the middle of the housing 1, and the stator 2 is arranged on the rotor 3 One end inside the housing 1 is provided with a partition 8, one side of the partition 8 is provided with the fan 4, and the other side of the partition 8 is provided with the stator 2 and the The rotor 3, the windshield 5 is arranged on the outside of the fan 4, the battery 6 is arranged below the fan 4, the outer wall of the housing 1 is radially distributed with cooling ribs, and the outer wall of the cooling rib has The outer cover plate is provided with heat dissipation grooves and heat dissipation holes, the heat dissipation grooves are provided with heat dissipation fins, and the heat dissipation fins are arranged in a dislocation manner with the heat dissipation holes.

[0022] The inside of the housing is also provided with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com