Rolling mill bearing demounting device

A rolling mill and bearing technology, which is applied in the field of rolling mill bearing maintenance equipment, can solve the problems of staff injury, hidden dangers, and complicated disassembly and assembly, and achieve the effects of improving disassembly and assembly efficiency, improving safety, and avoiding scattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

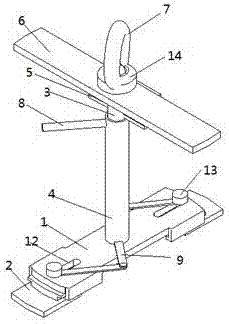

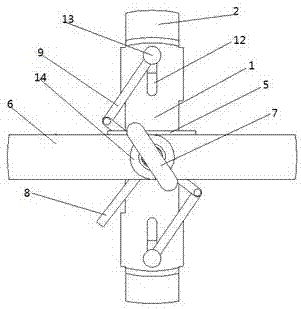

[0021] figure 1 and figure 2 It shows that a rolling mill bearing dismounting tool of the present invention includes a base 1 with a rectangular upper surface, a connecting rod 3 whose lower end is vertically fixed to the center of the upper surface of the base 1, and is sleeved on the connecting rod 3 and between the connecting rod 3 Rotating sleeve 4 with clearance fit, positioning plate 5 fixed on the upper part of connecting rod 3, rectangular bearing pressure plate 6 and suspension ring 7;

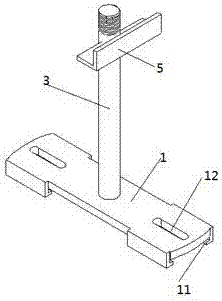

[0022] image 3 It shows that two ends of the base 1 are provided with two slideways 11 along the length direction of the base 1;

[0023] figure 1 and figure 2 It shows that two sliders 2 are slidably connected to the two slideways 11 respectively, and the two sliders 2 can slide telescopically along the length direction of the base 1 in the slideways 11; Shaped holes 12, the strip-shaped holes 12 extend along the length direction of the base, two hinge shafts 13 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com