Simple novel pipe clamp

A new type of pipe clamp technology, applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of inability to adapt to different lengths of hangers, inability to clamp pipes of different diameters, etc., to achieve easy installation and selection. Simple and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

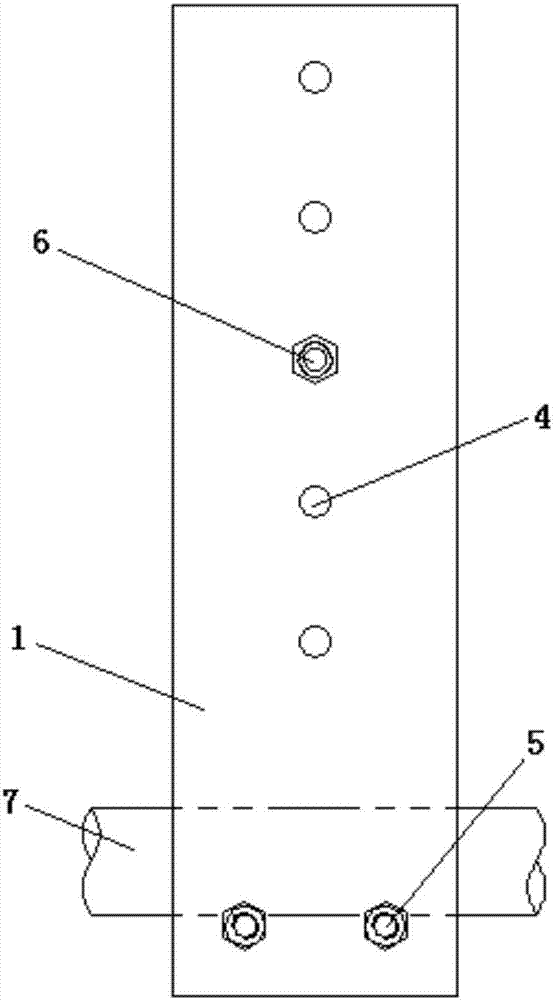

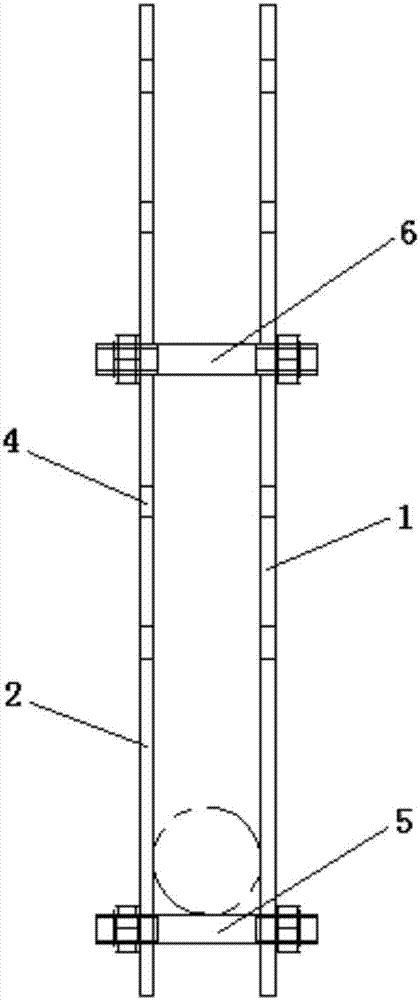

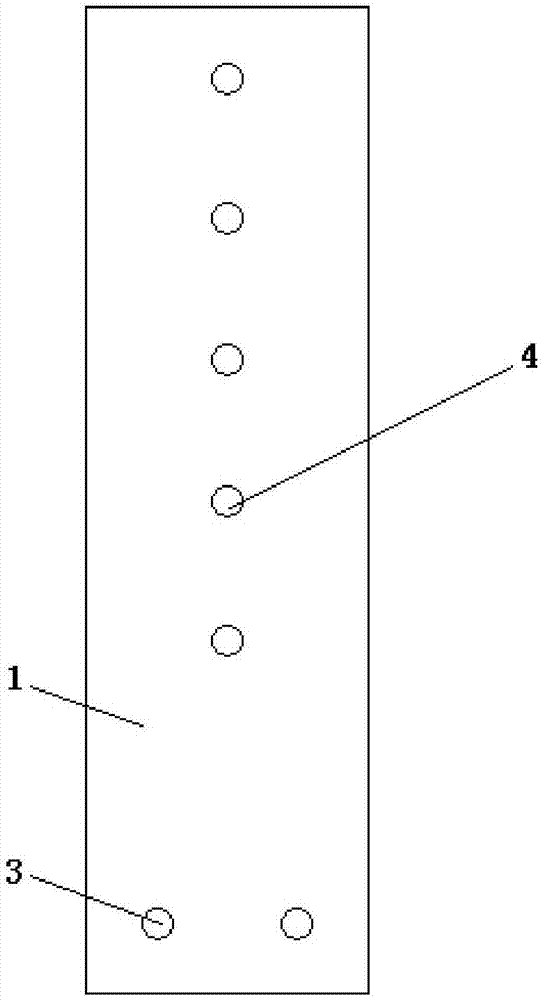

[0014] Such as Figure 1 to Figure 3 As shown, a simple new pipe clamp according to the present invention includes a first splint 1, a second splint 2, a first hanging hole 3, a second hanging hole 4, a first connecting rod 5 and a second connecting rod 6 ;

[0015] There are at least two first hanging holes 3 on the outer walls of the lower ends of the first splint 1 and the second splint 2, and a plurality of second hanging holes are also opened on the outer walls of the first splint 1 and the second splint 2. 4. The second hanging hole 4 is located above the first hanging hole 3, the first splint 1 and the second splint 2 are connected by the first connecting rod 5 and the second connecting rod 6, and the first connecting rod 5 and the first The hanging hole 3 is matched, and the second connecting rod 6 is matched with the second hanging h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com