Air bearing

A technology of carrier and air flotation, which is applied in the direction of instruments, measuring instrument components, measuring devices, etc., can solve the problems of difficult to maintain the level effect of the substrate, precise detection, easy accumulation of airflow, and bulging of the substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

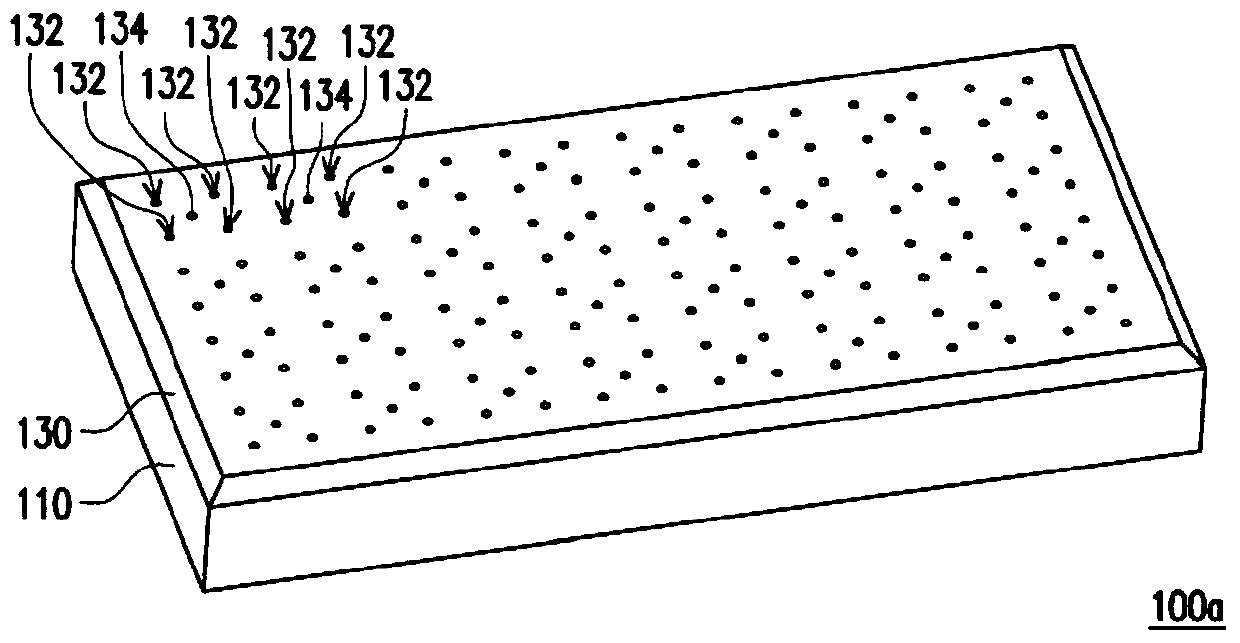

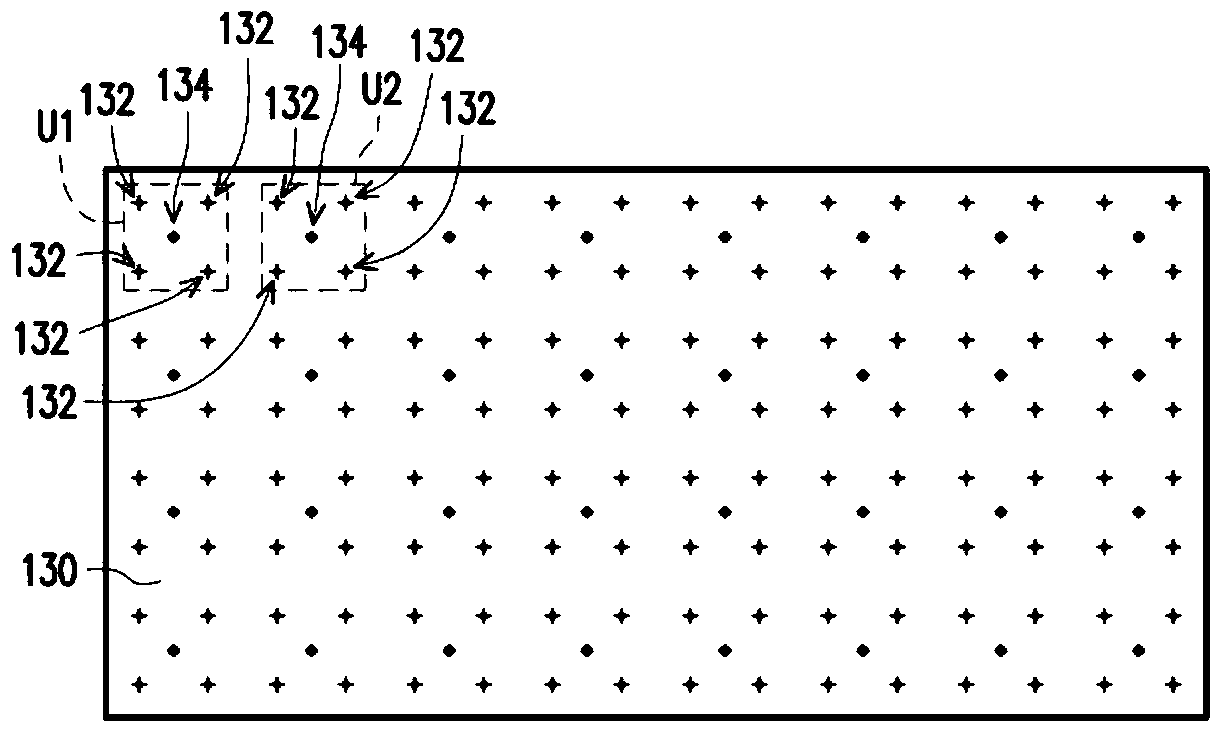

[0035] figure 1 is a schematic diagram of an air bearing platform according to an embodiment of the present invention. Please refer to figure 1 , in this embodiment, the air bearing platform 100 a includes a bottom layer 110 and a top layer 130 , and the top layer 130 is disposed above the bottom layer 110 . That is to say, the air bearing platform 100a is a double-layer structure composed of a bottom layer 110 and a top layer 130, wherein the bottom layer 110 and the top layer 130 are stacked together in sequence and fixed by fixing members (such as screws). Moreover, the air bearing stage 100a is suitable for providing airflow for carrying a substrate (not shown), such as glass or other objects to be inspected, so as to perform precise inspection on the substrate.

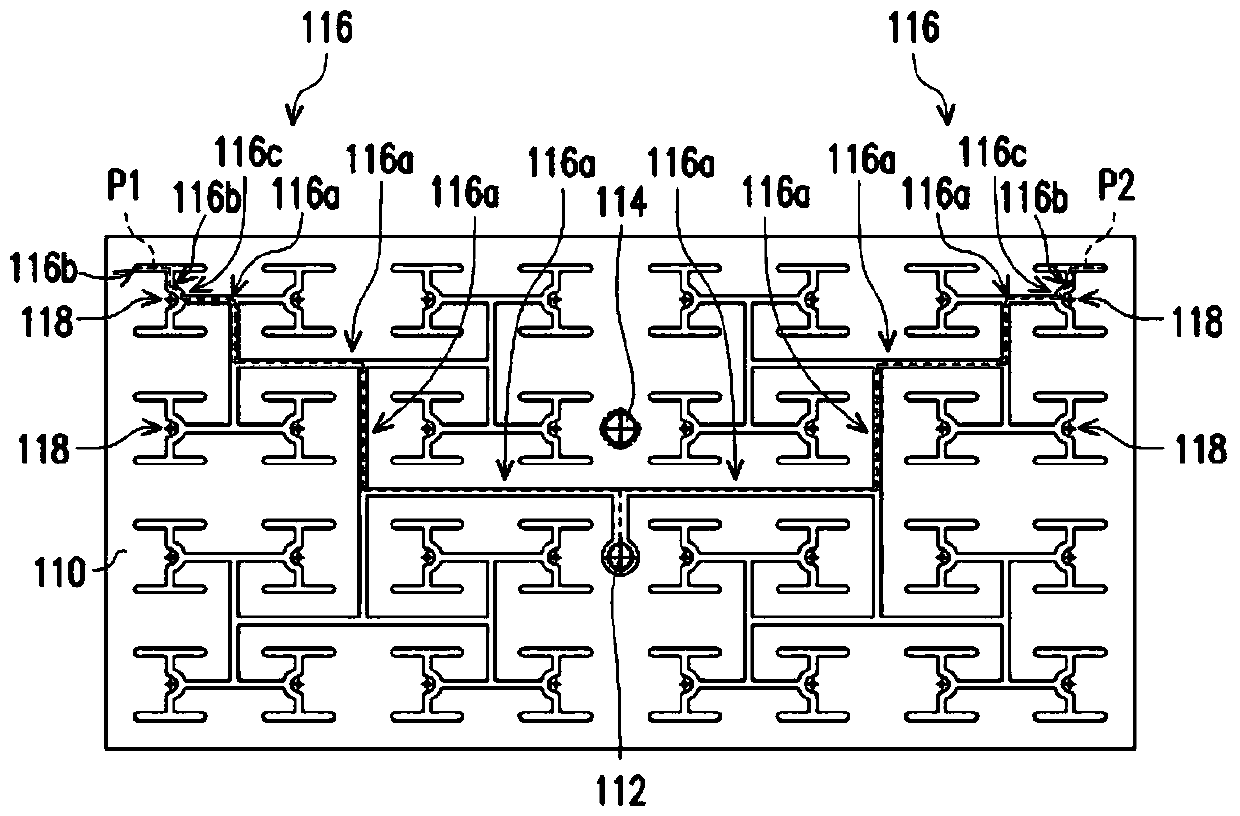

[0036] Specifically, in this embodiment, the air bearing platform 100a further includes a first airflow path and a second airflow path. The airflow is adapted to flow from the bottom layer 110 to the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com