A Method for Calculating the Thermal Efficiency of Pipelines in Large Thermal Power Plants

A thermal power plant, thermal efficiency technology, applied in computing, data processing applications, energy industry, etc., can solve problems such as overestimation, inaccurate pipeline efficiency, and underestimation of pipeline impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

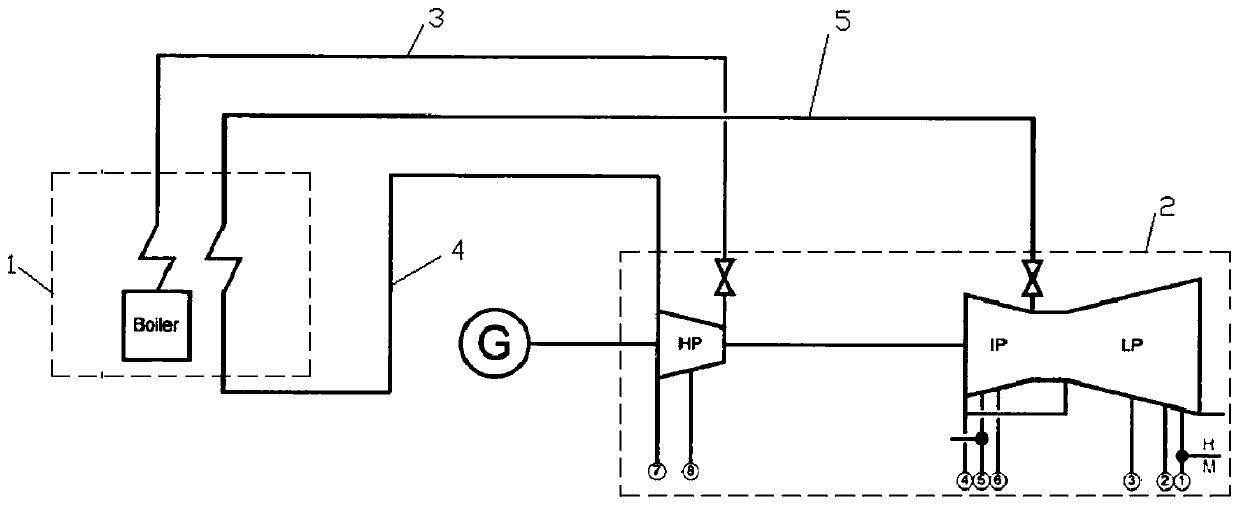

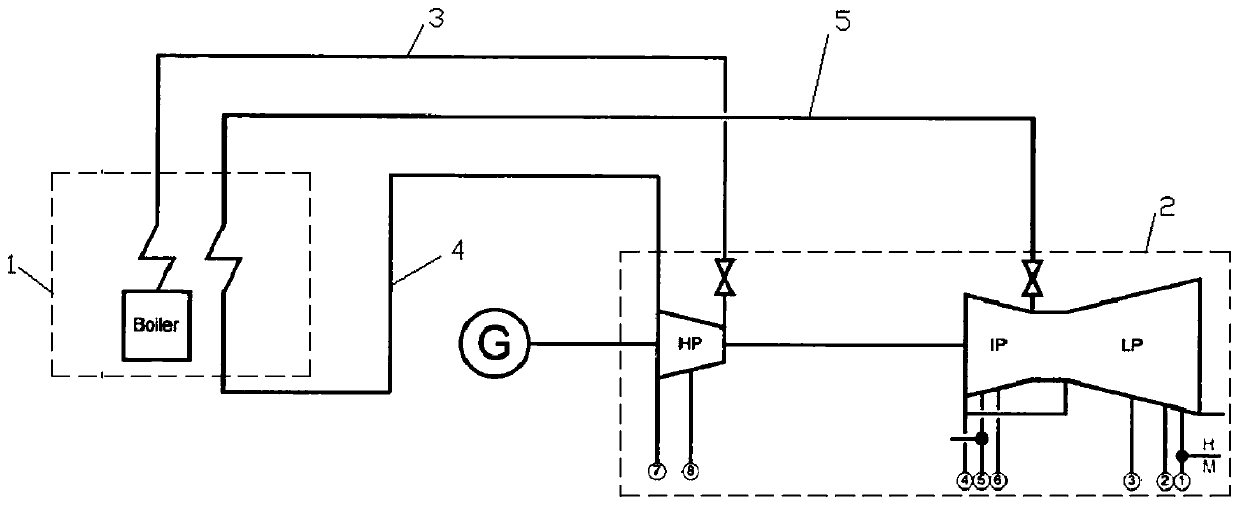

[0026] The present invention is mainly applicable to steam pipeline systems of large-scale (power generation greater than 125MW) thermal power plants, such as figure 1 , and its piping system includes main steam pipes, 3, cold reheating pipes 4 and hot reheating pipes 5. The boiler system 1 communicates with the steam turbine system 2 through the main steam pipeline 3, and the steam turbine system 2 flows back to the boiler system 1 through the cold reheat pipeline 4, and then enters the steam turbine system from the filter system 1 through the hot reheat pipeline 5.

[0027] Next, calculate the overall pipeline thermal efficiency of the main steam pipeline 3 , the cold reheat pipeline 4 and the hot reheat pipeline 5 using the method described in this application.

[0028] The specific calculation process of this embodiment is as follows.

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com