Method for assembling detachable drum

An assembly method and disassembly technology, applied in percussion instruments, instruments, musical instruments, etc., can solve the problems of complicated hand drum production, inconvenient tuning, waste of resources, etc., and achieve the effects of rich timbre, convenient tuning, and reduction of waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

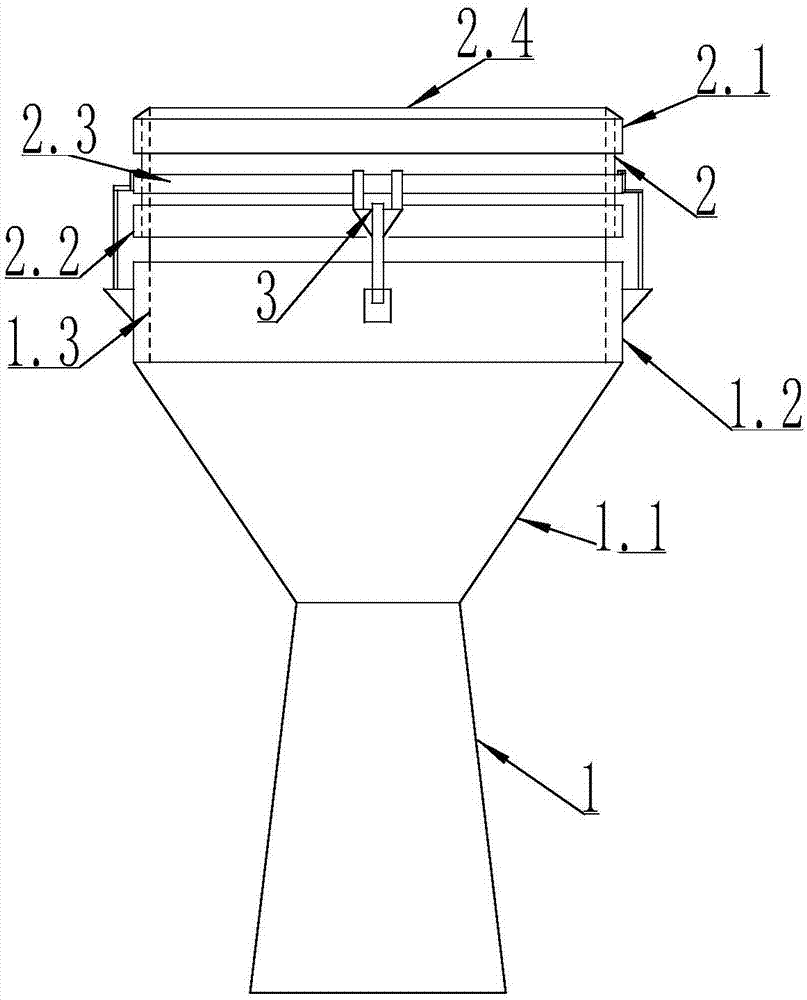

[0022] A funnel-shaped middle drum body 1.1 is arranged between the cylindrical upper drum body 1.2 and the inverted funnel-shaped lower drum body 1. The height of the middle drum body 1.1 is smaller than that of the lower drum body 1, and the cone surface of the middle drum body 1.1 is larger than that of the lower drum body. The cone surface of the body 1, a cylindrical support ring 1.3 is arranged in the upper drum body 1.2, and a drum cover is arranged on the upper periphery of the support ring 1.3, and at least four tuning connectors are evenly distributed between the upper drum body 1.2 and the drum cover 3. The upper end of the tuning connector 3 is set on the outer circumference of the drum cover, the lower end of the tuning connector 3 is set on the outer circumference of the upper drum body 1.2, and the drum cover is connected with the upper drum body 1.2 through the tuning connector 3. One;

[0023] The structure of the drum cover is as follows: the installation par...

Embodiment 2

[0025] The assembly method of the drum body is: the upper end of the inverted funnel-shaped lower drum body 1 is installed with the funnel-shaped middle drum body 1.1, and the upper end surface of the middle drum body 1.1 is sequentially installed with a cylindrical upper drum body 1.2 and a support ring from the outside to the inside. 1.3, the support ring 1.3 is located in the upper drum body 1.2;

[0026] The assembly method of the drum cover is as follows: the drum skin 2.4 is installed on the top of the drum skin ring sleeve 2.1, the outer peripheral edge of the drum skin 2.4 is fixedly installed in the drum skin ring sleeve 2.1, the drum skin ring sleeve 2.1 is installed on the upper end of the installation part 2, and the installation part 2 The lower end of the lower ring sleeve 2.2 is installed, and the fixed ring sleeve 2.3 is installed in the annular groove on the outer periphery of the installation part 2;

[0027] The drum cover is placed on the support ring 1.3, ...

Embodiment 3

[0029] The material of the drum skin 2.4 is PVC film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com